A kind of modified activated carbon filler and its preparation method and application

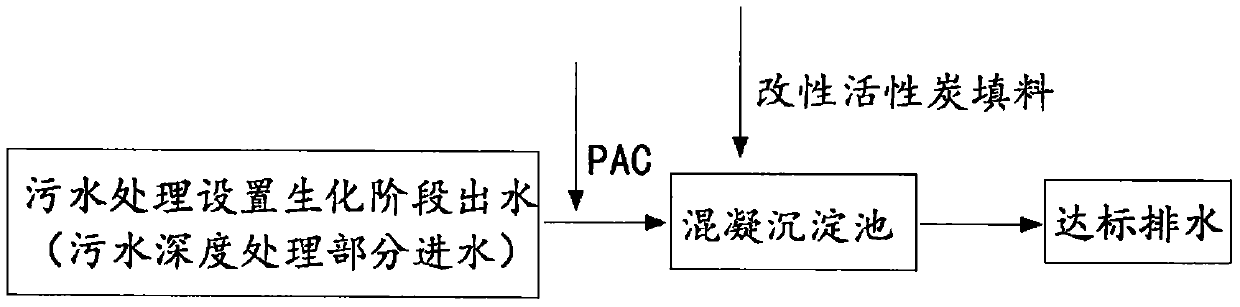

A technology of activated carbon and modification, which is applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc. The method is simple, the application effect is good, and the effect of improving physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] Based on the same inventive concept, the present invention also provides a specific preparation method for the above-mentioned modified activated carbon filler, which specifically includes the following steps:

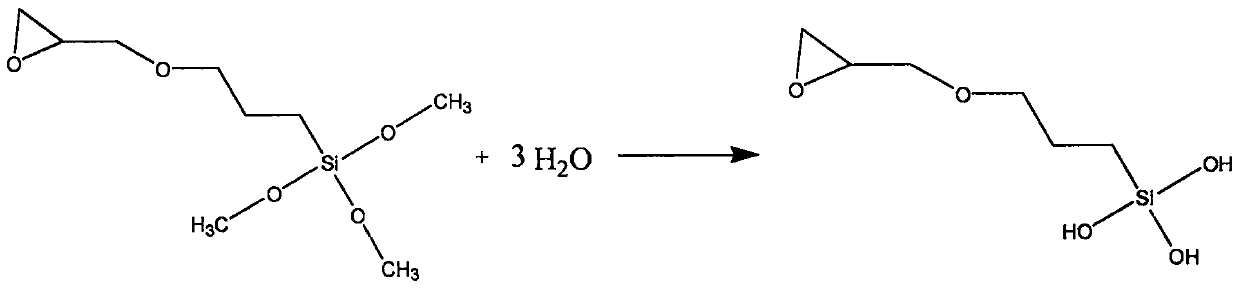

[0020] S1: Mix γ-(2,3-glycidoxy)propyltrimethoxysilane, water and alcohol solvent evenly according to the volume ratio of 1:1-2:15-30, and adjust the pH value at 5.2-5.5 , the reaction time is controlled at 6-6.5 hours, and a completely hydrolyzed turbid appearance gamma-(2,3-glycidyloxy)propyltrimethoxysilane hydrolyzate is obtained;

[0021] Concrete chemical reaction is as shown in formula (I):

[0022]

[0023] S2: Mix the prepared γ-(2,3-glycidyloxy)propyltrimethoxysilane hydrolyzate, activated carbon and alcohol solvent according to the ratio of 1L hydrolyzate: 900-1200g activated carbon: 1-2L alcohol solvent, and stirring, adjusting the pH value at 6.0-6.5, and controlling the reaction time at 7-8 hours to obtain the modified activated carbon filler; ...

Embodiment 1

[0028] Measure 100mL of γ-(2,3-glycidyloxy)propyltrimethoxysilane, 150mL of water and 2000mL of 75% ethanol respectively, mix the weighed components in the reactor, and stir , until uniform, adjust the pH value of the solution at 5.5, and control the reaction time at 6.5 hours to obtain a completely hydrolyzed turbid appearance gamma-(2,3-glycidoxy)propyltrimethoxysilane hydrolyzate;

[0029] Measure the turbid appearance γ-(2,3-glycidoxy) propyltrimethoxysilane hydrolyzate 1000mL, activated carbon 900g, 75% ethanol 2000mL of the thoroughly hydrolyzed appearance turbid type prepared above, and thoroughly hydrolyze The turbid appearance gamma-(2,3-glycidyloxy) propyltrimethoxysilane hydrolyzate is mixed with the above-mentioned activated carbon and 75% ethanol and fully stirred, the pH value is adjusted at 6.2, and the reaction time is controlled at 7.8 hours to prepare Obtain a fully modified liquid activated carbon filler;

[0030] The fully modified liquid activated carbon ...

Embodiment 2

[0032] Measure 100mL of γ-(2,3-glycidyloxy)propyltrimethoxysilane, 100mL of water and 1500mL of 90% ethanol respectively, mix the weighed components in the reactor, and stir , until uniform, adjust the pH value of the solution at 5.2, and control the reaction time at 6 hours to obtain a completely hydrolyzed turbid appearance gamma-(2,3-glycidoxy)propyltrimethoxysilane hydrolyzate;

[0033] Measure 1000 mL of the thoroughly hydrolyzed appearance turbid type γ-(2,3-glycidyloxy) propyltrimethoxysilane hydrolyzate, 1000 g of activated carbon, and 1500 mL of 90% ethanol obtained above. The turbid appearance gamma-(2,3-glycidyloxy) propyltrimethoxysilane hydrolyzate is mixed with the above-mentioned activated carbon and 90% ethanol and fully stirred, the pH value is adjusted at 6.0, and the reaction time is controlled at 7 hours. Obtain a fully modified liquid activated carbon filler;

[0034] The fully modified liquid activated carbon filler was placed in a 40°C constant temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com