A surface strengthening method for reducing the porosity of laser additive parts

A laser additive and surface strengthening technology, used in the fields of laser shock, laser additive manufacturing, and laser welding to achieve the effect of improving fatigue resistance and strengthening materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

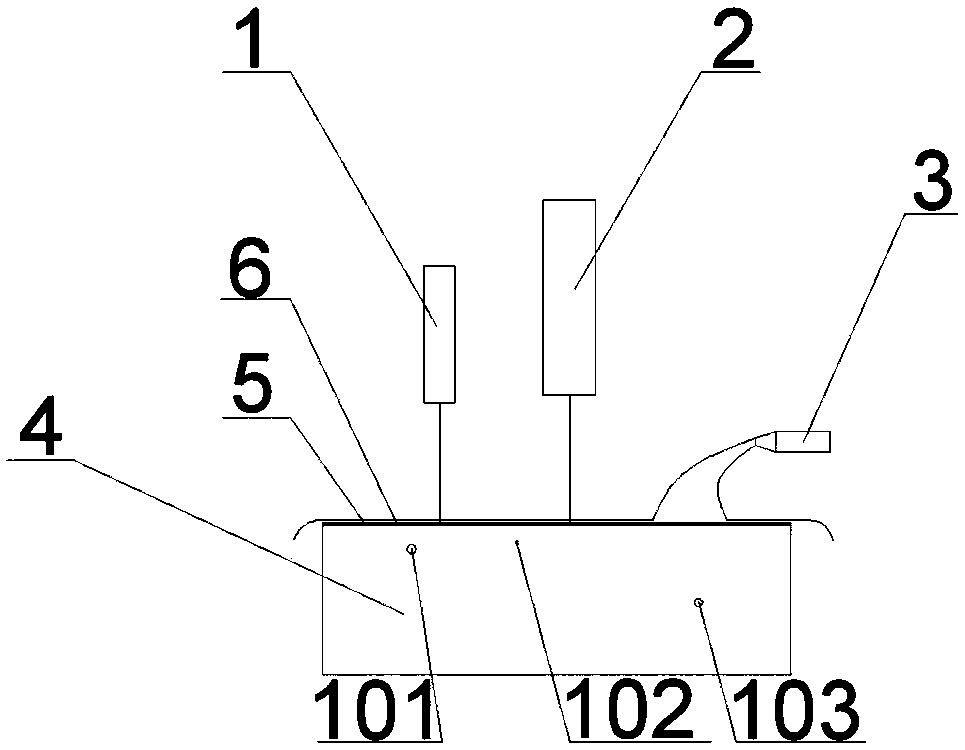

[0025] Firstly, X-ray 1 tomographically scans the surface of the part 4 manufactured by laser additive manufacturing, and detects the distribution of pores inside the part. The surface of the part is coated with an absorbing layer 6 and a water-constrained layer 5 is applied by a water-coating robot, and the laser 2 enters a standby mode for laser shock. Input the pore parameters into the industrial computer, and the industrial computer formulates the laser shock strategy according to the distribution and size of the pores:

[0026] When the first air hole 101 is close to the surface (0-1.5mm) and the diameter of the air hole 101 is relatively large (10um-20um), the medium-sized laser energy (10J-15J) is used to shock the surface of the part 4, and the shock wave is A back and forth reflection between the walls of a pore 101 will generate residual compressive stress in the material around the hole wall, preventing the hole wall from becoming a source of cracks.

[0027] When ...

specific Embodiment 2

[0029] Specific embodiment 2: use laser energy 8J, pulse width 22ns, repetition frequency 0.5Hz, spot diameter 6mm, overlap rate 50% of the laser to impact the two sides of the material, and generate pore compression zone CP on both sides of the material.

[0030] Such as Figure 2c , 2d Shown is the change of the pores P in the tensile fracture of the aluminum alloy weld before and after the double-sided laser impact. Figure 2c The middle area I is the impact area, and II is the non-impact area. It can be clearly seen that the pores P are reduced after the impact, and the material structure is refined. The porosity decreased from 2.42% before impact to 0.82%, and the tensile strength increased from 203.98MPa to 237.9MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com