Jet lubrication structure

A spray-type, structural technology, applied in the direction of pressure lubricant, engine lubrication, machine/engine, etc., can solve the problems of high frictional resistance between the piston and the cylinder hole, the heat cannot be dissipated in time, and the top of the piston is burned to achieve lubrication. Good effect, improve power output or transmission efficiency, and reduce friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

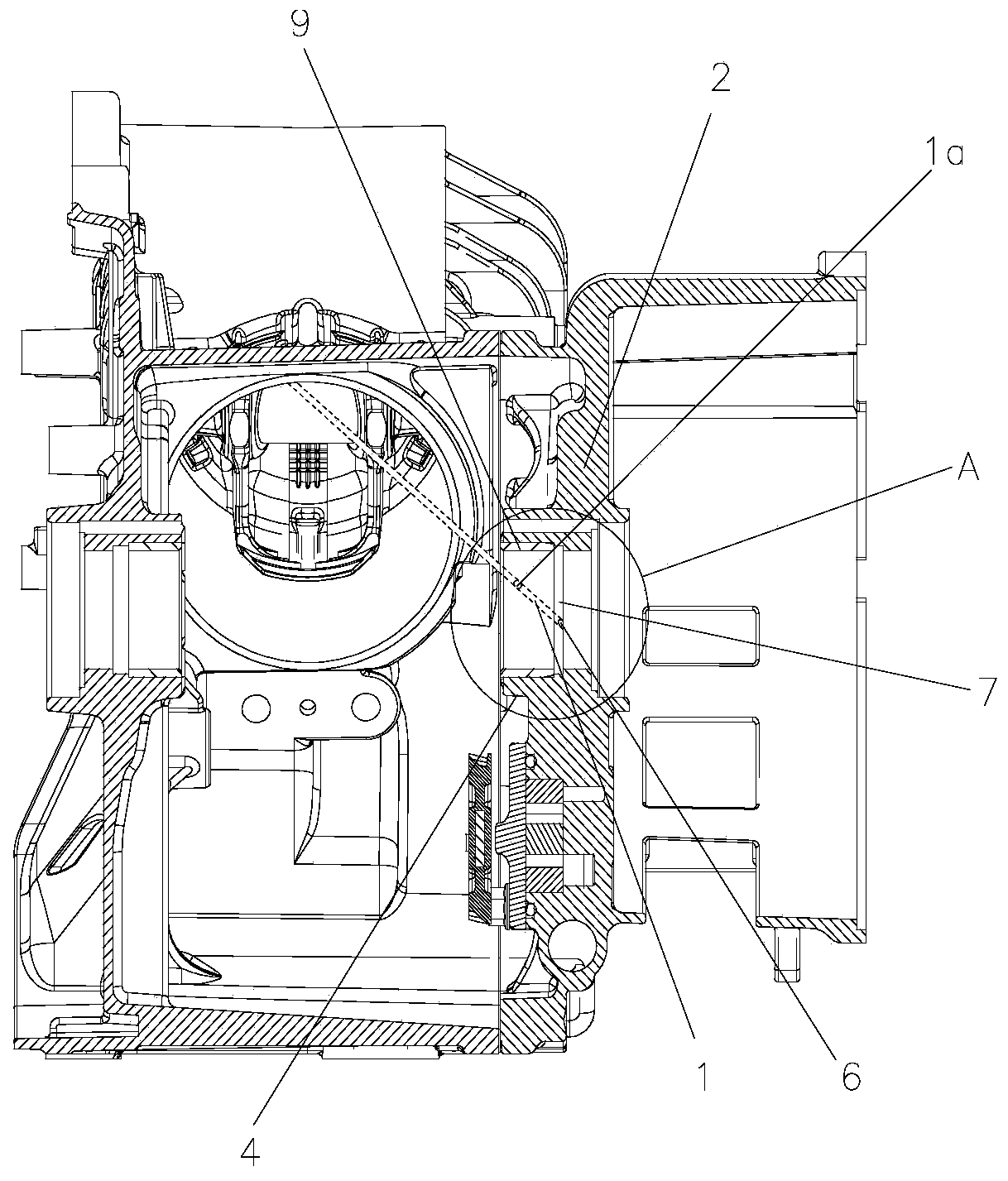

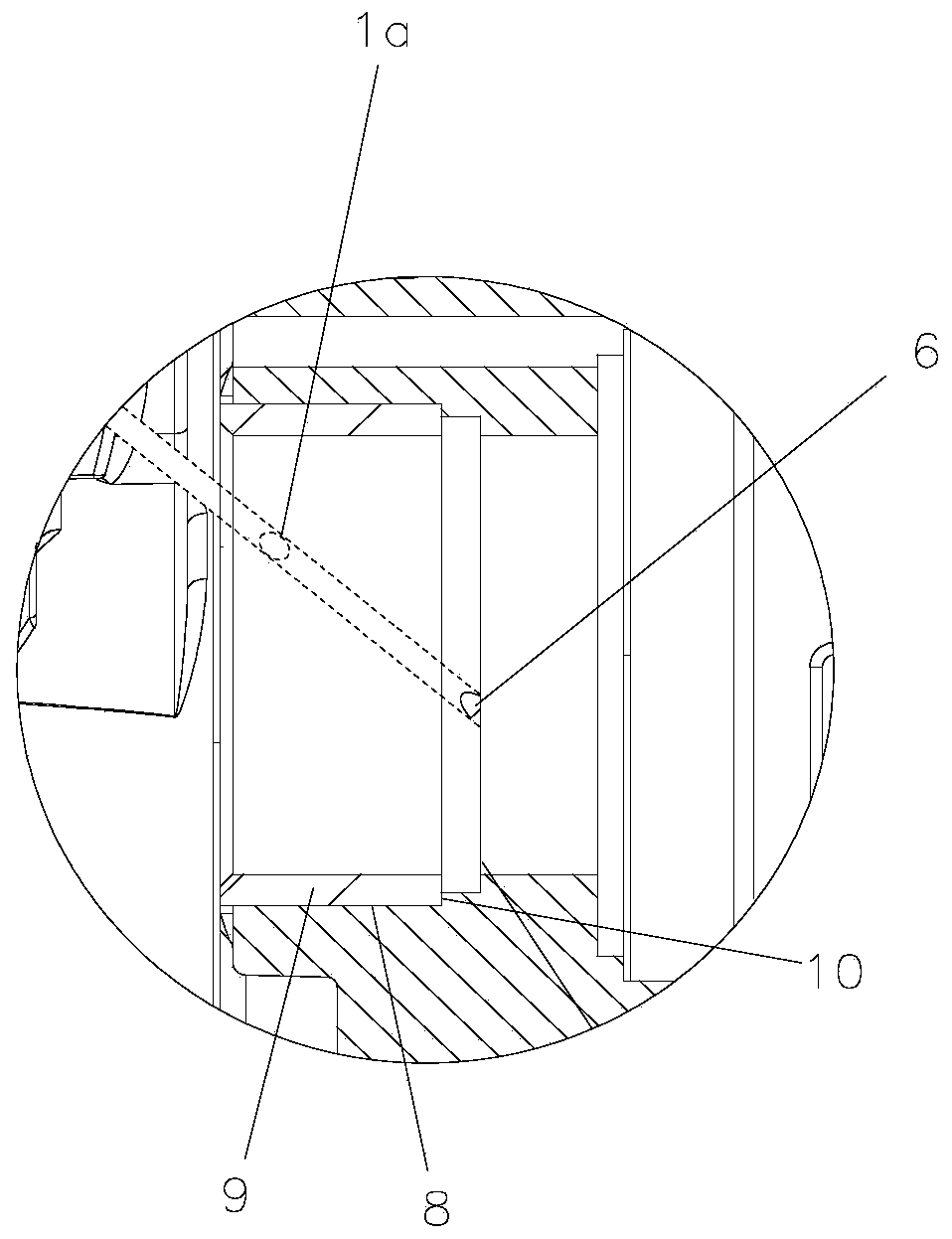

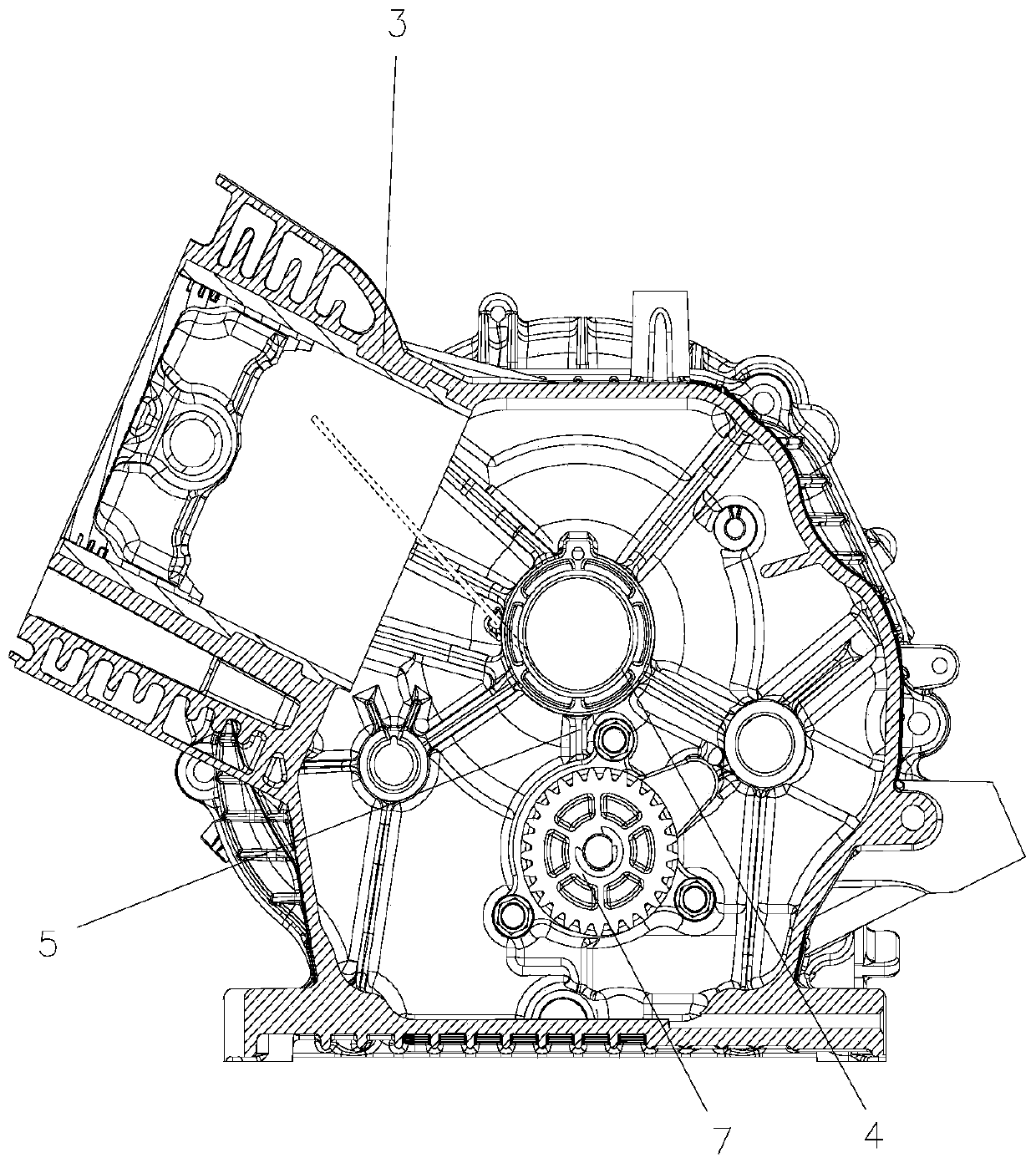

[0022] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 Enlarged view of A in the middle, image 3 It is another schematic diagram of the structure of the present invention, as shown in the figure, the injection lubrication structure in this embodiment includes an injection oil channel 1 arranged in the box, the injection oil channel 1 has an oil injection port 1a, and the injection oil channel 1 The oil injection direction of the oil port 1a is facing the piston cavity of the box body; the box body includes the crankcase and the cylinder 3 fixed to the crankcase, as shown in the figure, the crankcase includes the crankcase body and the crankcase cover 2, this Embodiment The injection oil passage 1 is arranged on the crankcase cover 2 of the crankcase. Of course, there is injection machine oil with a certain pressure in the injection oil passage 1. At the same time, the oil injection direction of the oil injection port 1a is faci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com