A method for writing apodized fiber gratings

A fiber grating and apodization technology, applied in the directions of cladding fiber, optical waveguide light guide, light guide, etc., can solve the problems of modulation asymmetry, optical fiber core photosensitive refractive index modulation asymmetry, limited control accuracy, etc., to eliminate The effect of asymmetry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

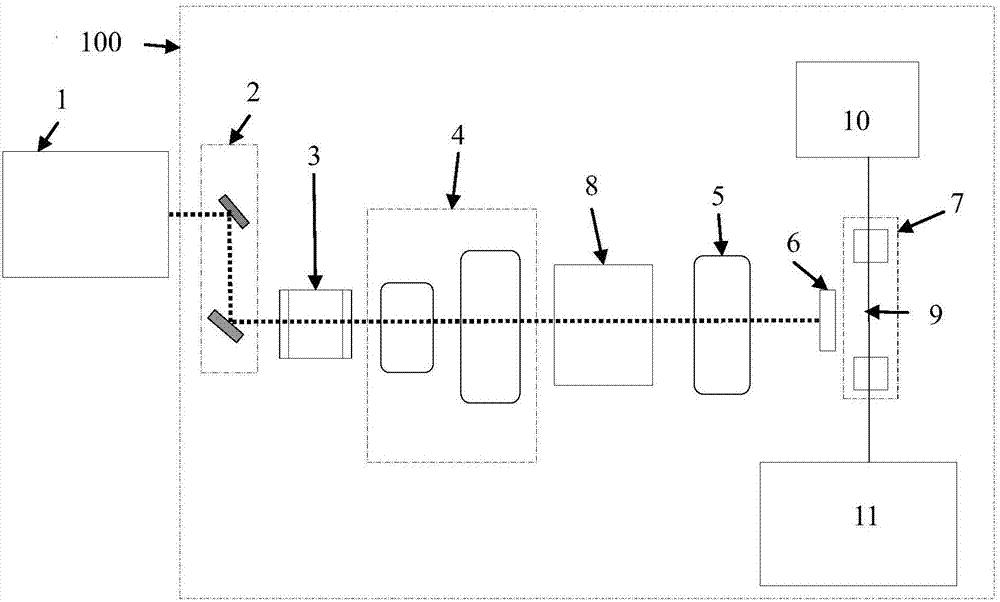

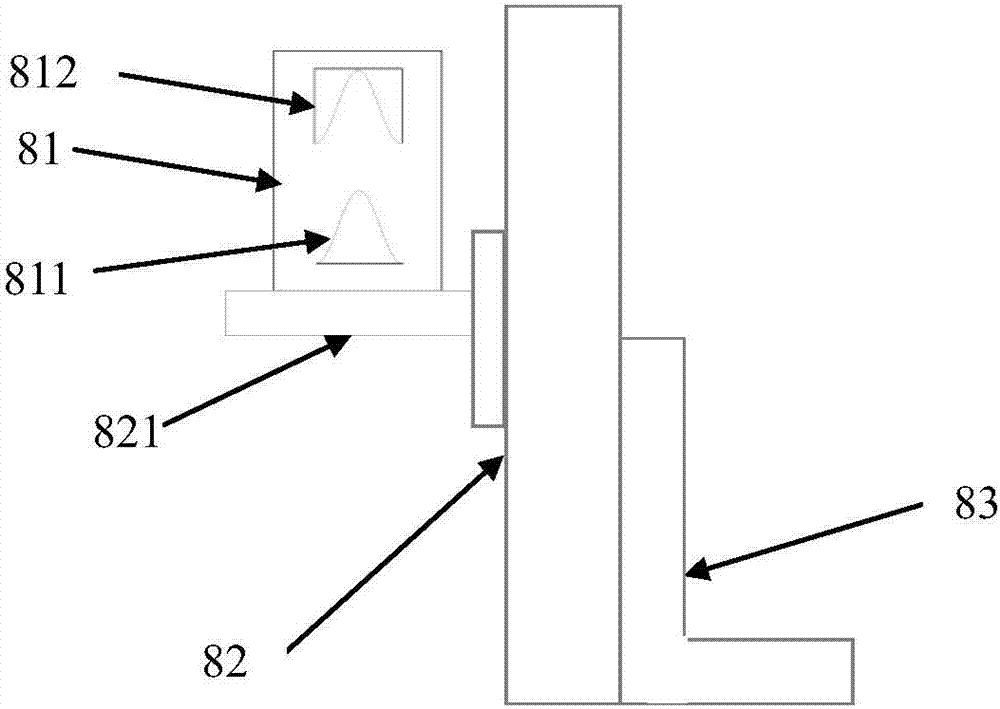

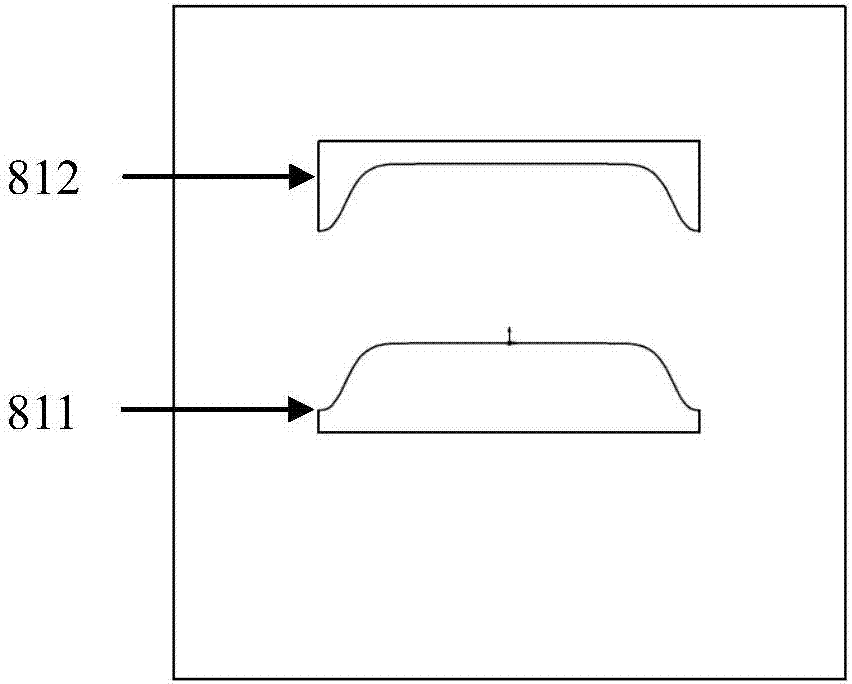

[0033] Such as figure 1 and figure 2 As shown, the apodized fiber grating writing system of the present invention includes an optical platform 100, an excimer laser 1, a mirror group 2, a diaphragm 3, a beam expanding cylindrical lens group 4, a focusing cylindrical lens 5, a phase mask 6 and a fiber clamp holding device 7, reflector group 2 is installed on the optical platform 100 for adjusting the position and height of excimer laser 1 outgoing beam, diaphragm 3, beam expanding cylindrical lens group 4, focusing cylindrical lens 5, phase mask 6 and optical fiber The clamping device 7 is sequentially arranged on the optical table 100 along the outgoing direction of the outgoing light beam reflected by the mirror group 2, and an apodization device 8 is arranged between the beam expander cylindrical lens group 4 and the focusing cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com