Preparation method and application of sulfur nano-particle dispersion liquid

A nanoparticle and dispersion technology is applied in the field of preparation of sulfur nanoparticle dispersion, which can solve the problems of unfavorable improvement of electrochemical performance, uneven material size, limited feasibility, etc. , the effect of improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

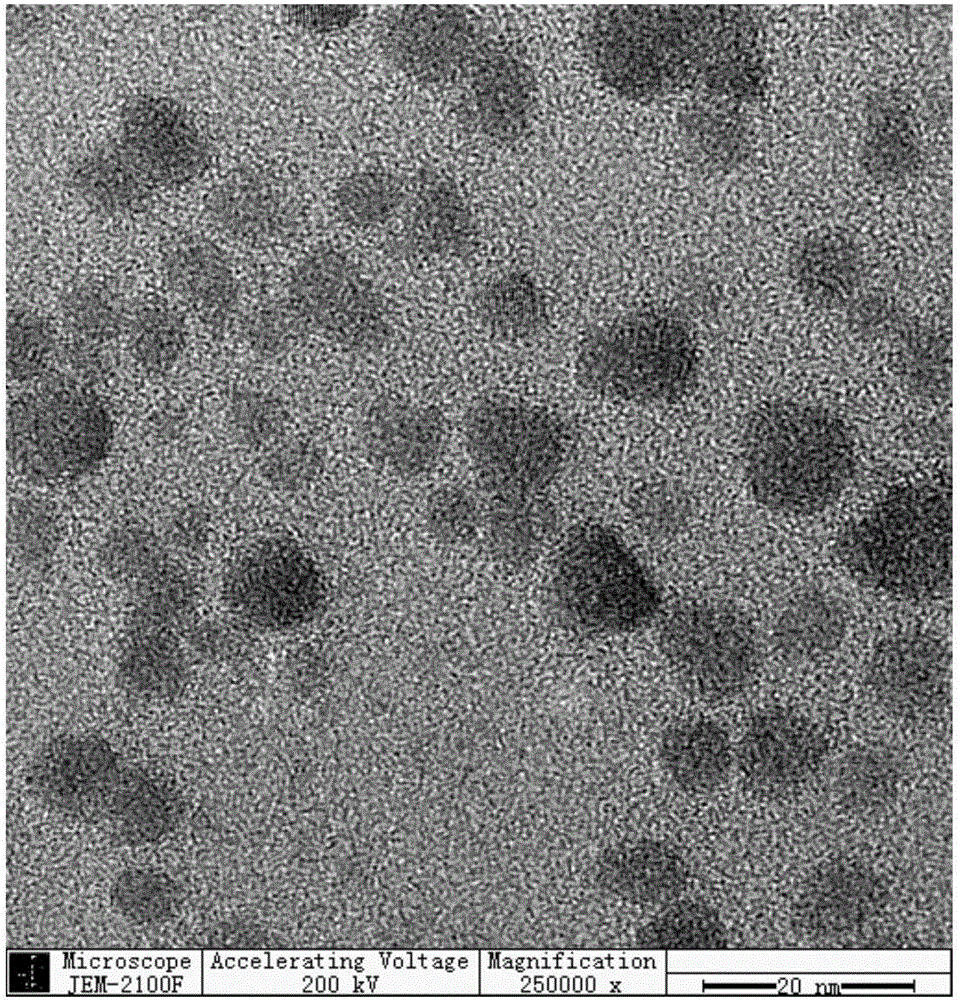

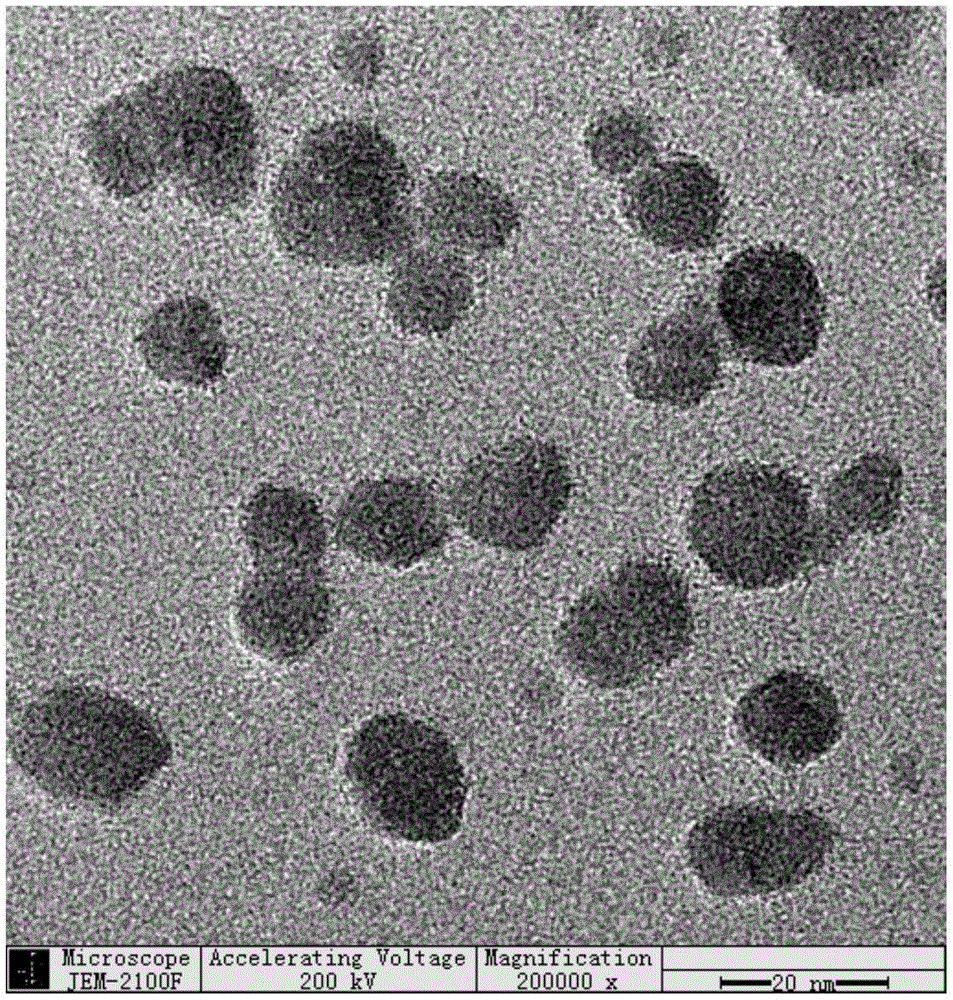

Image

Examples

Embodiment 1

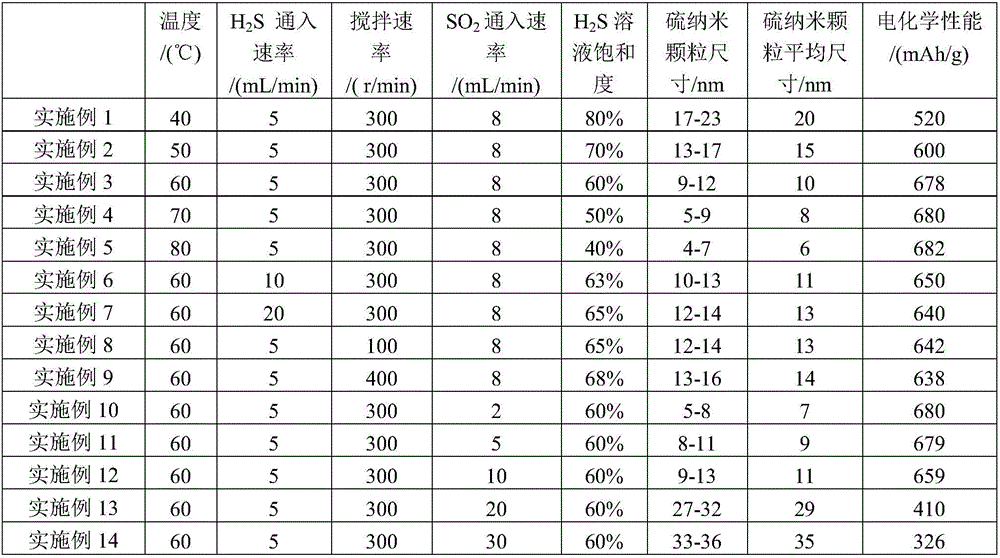

[0022] Embodiment 1: the hydrogen sulfide gas is passed into the container that fills 100mL deionized water, under the situation of 40 ℃, keep 20min, take the deionized water of unit volume (1L) as a benchmark, the rate of passage is 5mL / min, So that part of the hydrogen sulfide gas is dissolved in water, the saturation is 80%, keep fully stirring 300r / min in this process, guarantee the uniform distribution of hydrogen sulfide gas; The injection rate was 8mL / min, while keeping the hydrogen sulfide input rate constant, the two gases were jointly injected into the water phase for 20 minutes, and after the solution appeared pale white, the gas was stopped, and the obtained pale white solution was the sulfur nanoparticle dispersed solution. liquid. The particle size distribution and electrochemical performance of the prepared sulfur nanoparticle dispersion are shown in Table 1.

Embodiment 2

[0023] Embodiment 2: The process of this embodiment is the same as that of Embodiment 1, except that the reaction temperature is changed to 50°C. The rest are the same as in Embodiment 1, and will not be repeated here. The particle size distribution and electrochemical performance of the prepared sulfur nanoparticle dispersion are shown in Table 1.

Embodiment 3

[0024] Embodiment 3: The process of this embodiment is the same as that of Embodiment 1, except that the reaction temperature is changed to 60°C. The rest are the same as in Embodiment 1, and will not be repeated here. The particle size distribution and electrochemical performance of the prepared sulfur nanoparticle dispersion are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com