Fuel cell metal pole plate multiphase coating for suppressing columnar crystals and preparation method thereof

A metal plate and fuel cell technology, which is applied to fuel cell components, battery electrodes, circuits, etc., can solve the problems of low bonding ability between the coating and the substrate, large internal stress, etc., and achieve excellent substrate bonding performance and prolong Life expectancy, effect of growth improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

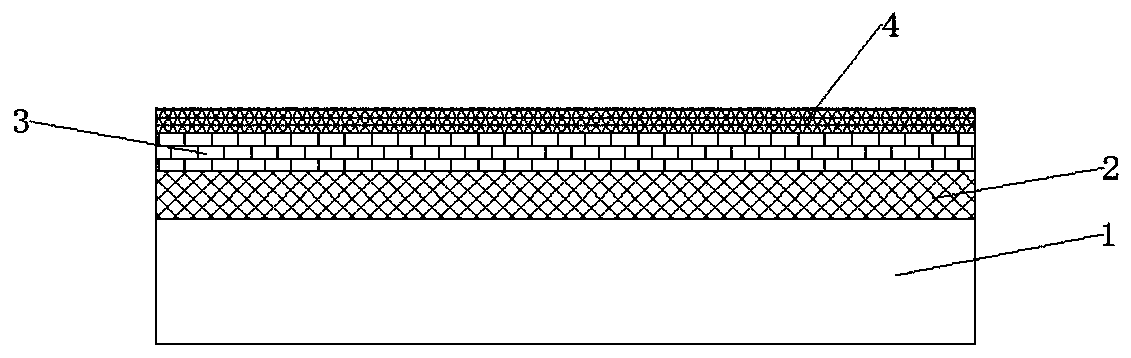

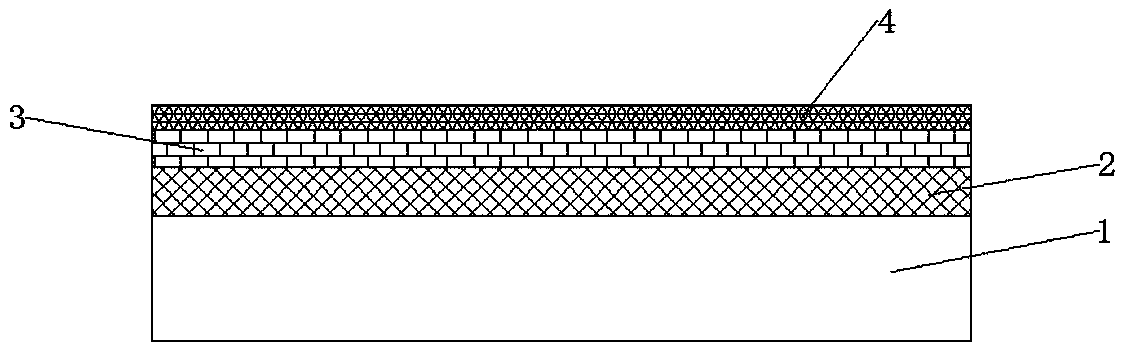

Image

Examples

Embodiment 1

[0039] Preparation method of Ti and Al multiphase coating for metal electrode plate of proton exchange membrane fuel cell:

[0040] (1) Surface pretreatment: After cleaning the stainless steel metal electrode plates with alkali solution and acid solution respectively, they are cleaned with deionized water, and then placed in absolute ethanol, acetone, and absolute ethanol for ultrasonic vibration treatment. Remove the oil stains on the surface of the metal plate to obtain a clean metal plate;

[0041] (2) Put the cleaned metal plates into the chamber of the unbalanced magnetron sputtering ion plating furnace and vacuumize to less than 3×10 -5 torr, filled with argon gas, working pressure maintained at 4×10 -4 Torr, the substrate bias voltage of the metal plate is -600V, the ion source is turned on for ion bombardment to remove the passivation layer of the substrate, the ion plating sputtering cleaning process time is 30min, the plate is hung on the rotating support, and the support ...

Embodiment 2

[0047] A Ti and Si multiphase coating used for the metal electrode plate of proton exchange membrane fuel cell and its preparation method:

[0048] (1) Surface pretreatment: After cleaning the stainless steel metal electrode plates with alkali solution and acid solution respectively, they are cleaned with deionized water, and then placed in absolute ethanol, acetone, and absolute ethanol for ultrasonic vibration treatment. Remove the oil stains on the surface of the metal plate to obtain a clean metal plate;

[0049] (2) Put the cleaned metal plates into the closed-field unbalanced magnetron sputtering furnace cavity and vacuumize to less than 3×10 -5 torr, filled with argon gas, working pressure maintained at 4×10 -4 Torr, the substrate bias voltage of the metal plate is -600V, the ion source is turned on for ion bombardment to remove the passivation layer of the substrate, the sputtering cleaning process time is 30 minutes, the plate is hung on the rotating support, and the suppor...

Embodiment 3

[0055] A Ti and Nb multiphase coating used for the metal electrode plate of a proton exchange membrane fuel cell and a preparation method thereof:

[0056] (1) Surface pretreatment: After cleaning the stainless steel metal electrode plates with alkali solution and acid solution respectively, they are cleaned with deionized water, and then placed in absolute ethanol, acetone, and absolute ethanol for ultrasonic vibration treatment. Remove the oil stains on the surface of the metal plate to obtain a clean metal plate;

[0057] (2) Put the cleaned metal plates into the cavity of the radio frequency sputtering furnace and vacuumize to less than 3×10 -5 torr, filled with argon gas, working pressure maintained at 4×10 -4 Torr, the substrate bias voltage of the metal electrode plate is -600V, the ion source is turned on for ion bombardment to remove the passivation layer of the substrate, the cleaning process time is 30 minutes, the electrode plate is hung on the rotating support, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com