Paper-plastic composite woven bag and production process thereof

A paper-plastic compounding and production process technology, applied in the direction of synthetic resin layered products, paper/cardboard layered products, bags, etc., can solve the problem of the deterioration of the items in the bag, the inability to effectively waterproof, moisture-proof, mildew-proof, and the durability of the composite bag. not long issue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] 1. The paper-plastic composite woven bag structure of the present invention

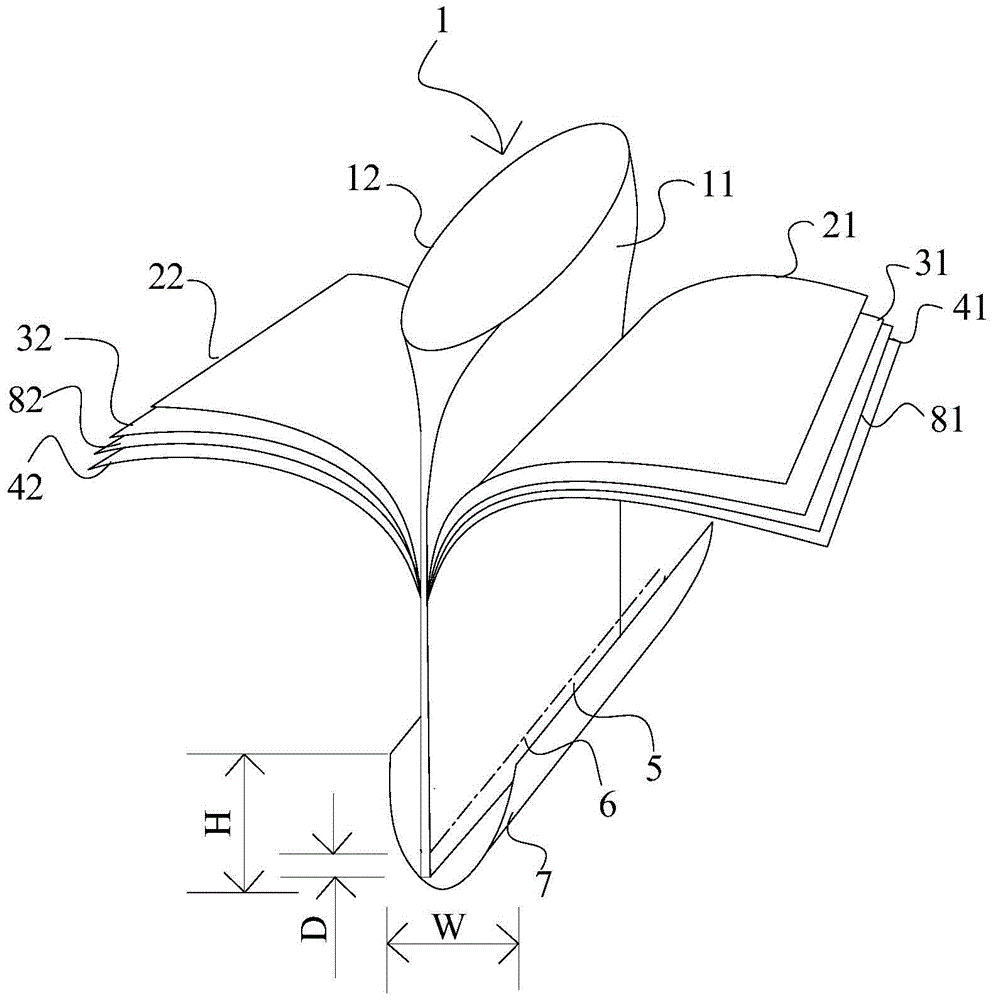

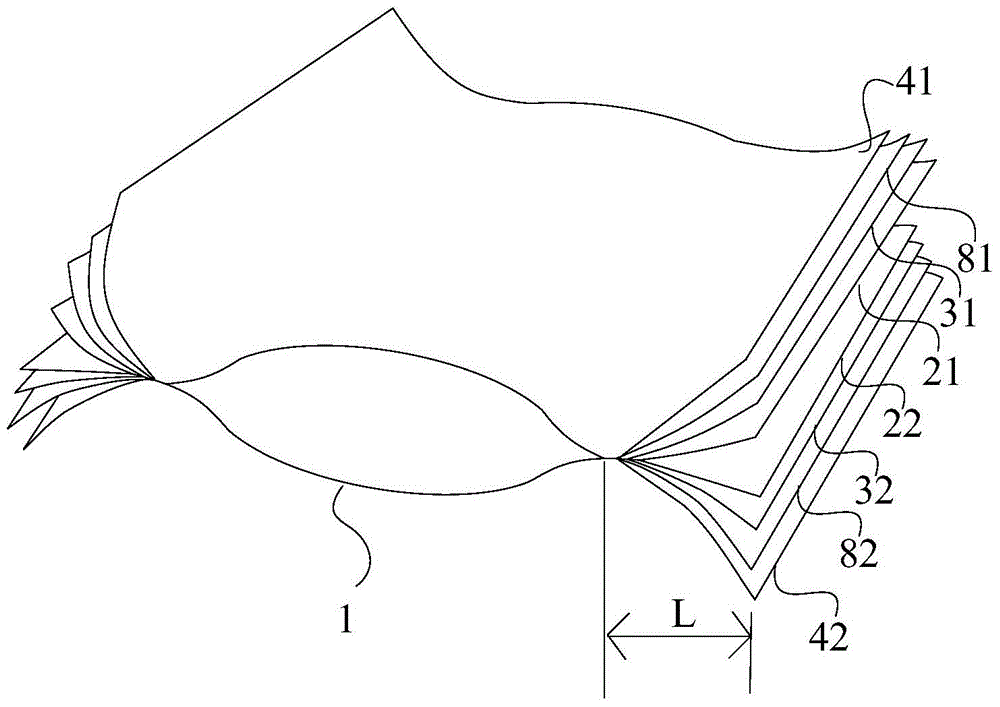

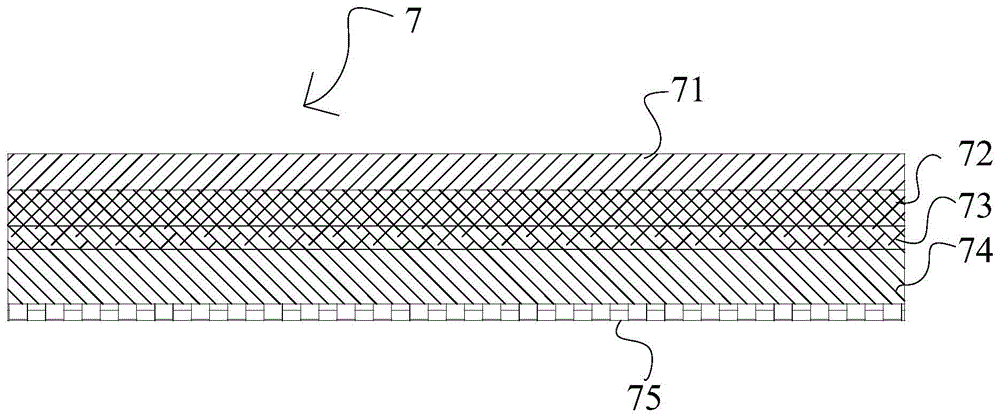

[0075] figure 1 A paper-plastic composite woven bag is shown. The paper-plastic composite woven bag includes a bag body 1 for holding articles, an adhesive layer, a high barrier material layer, a polyethylene material layer and a kraft paper layer. Wherein, the adhesive layer is coated on the outer surface of the bag body 1; the high barrier material layer is coated on the outer surface of the adhesive layer, and the high barrier material layer can block the gas in the bag body 1 Leakage: the polyethylene material layer is coated on the outer surface of the high barrier material layer, and the kraft paper layer is coated on the outer surface of the polyethylene material layer.

[0076] In addition, the bag body 1 is a cylindrical polypropylene woven bag with open upper and lower ends, and the material of the adhesive layer includes ethylene propylene polymer resin.

[0077] Please combine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com