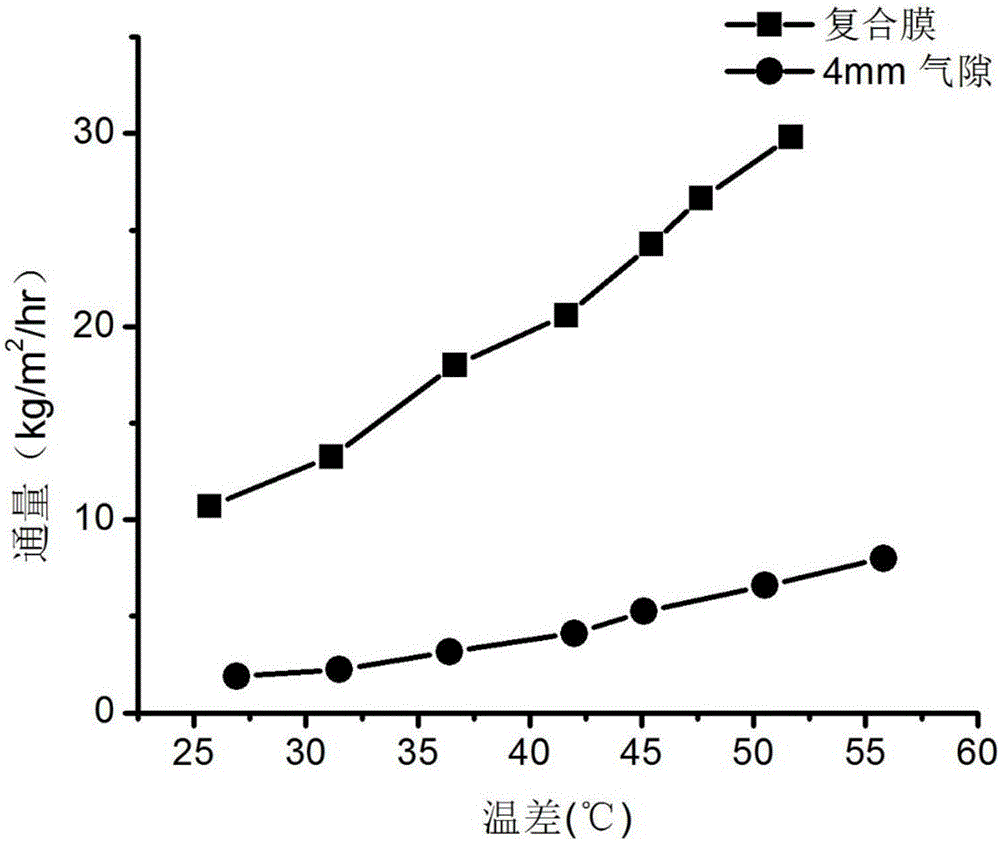

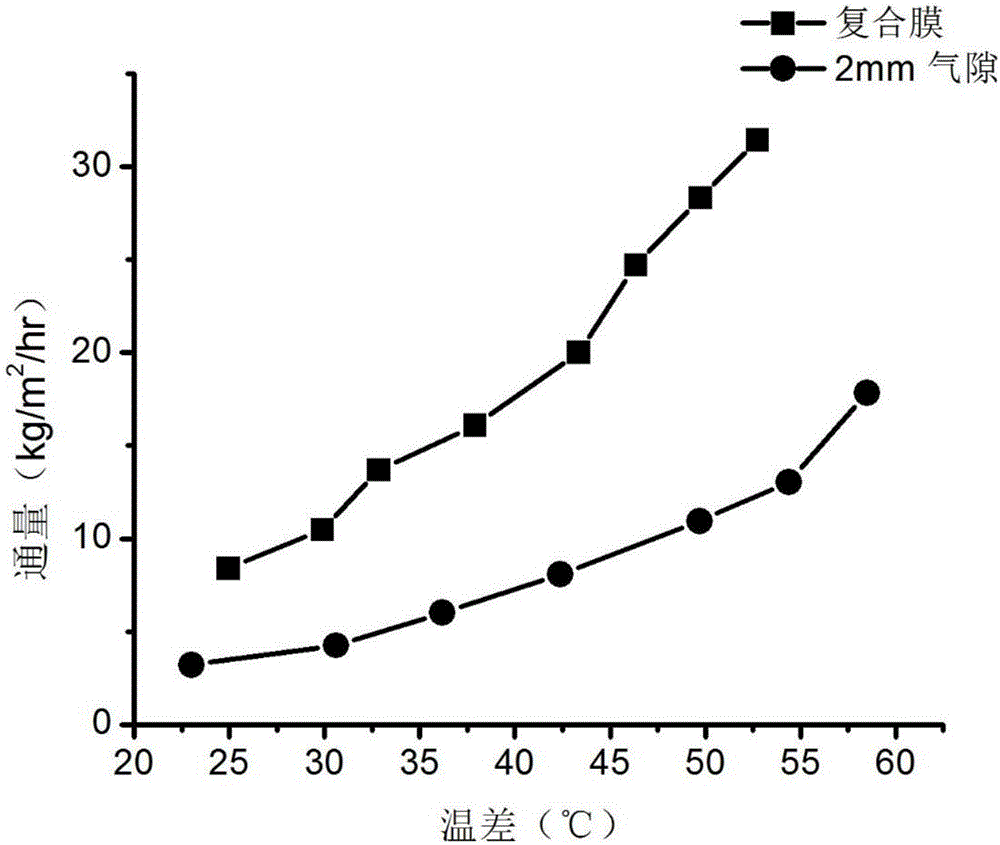

Composite membrane structure for desalting air gap type membranes

A composite membrane and thin film technology, applied in the field of chemical engineering, can solve the problems of unit flux limitation and increase the complexity of the structure, and achieve the effects of simplifying the structure, increasing the unit water purification capacity, and increasing the unit steam throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0011] A film of composite structure or post-processing of an existing film, comprising a film layer and a coarse fiber layer. The desalination film layer is a hydrophobic material, and the thick fiber layer can be either a hydrophobic material or a hydrophilic material. The material of the thick fiber can be a hydrophilic material, such as nylon, etc.; it can also be a hydrophobic material, such as polyvinylidene fluoride, polytetrafluoroethylene, polypropylene, etc.

[0012] The invention is a novel composite membrane material in which thick fibers are attached to the membrane. The production method can directly spray and attach the crude fiber to the film; it can also make the crude fiber in advance and then attach it to the existing film. Coarse fibers can be produced by spinning technology, or by stretching a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com