A sorting and processing device for urban organic waste

A technology for organic waste and treatment equipment, which is applied in grain treatment, solid waste removal, etc., can solve the problems of fixed structure and poor separation efficiency, and achieve the effect of high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

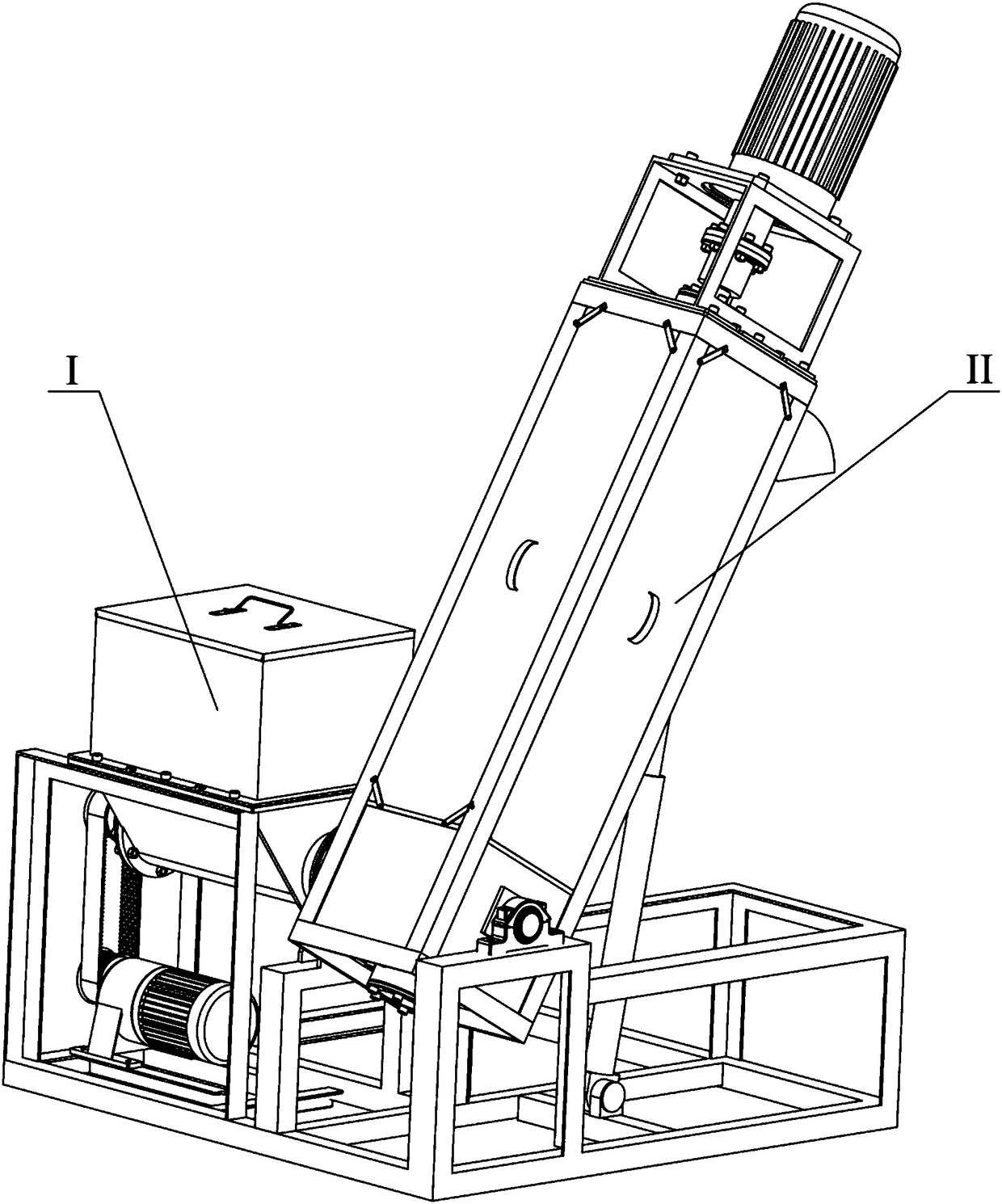

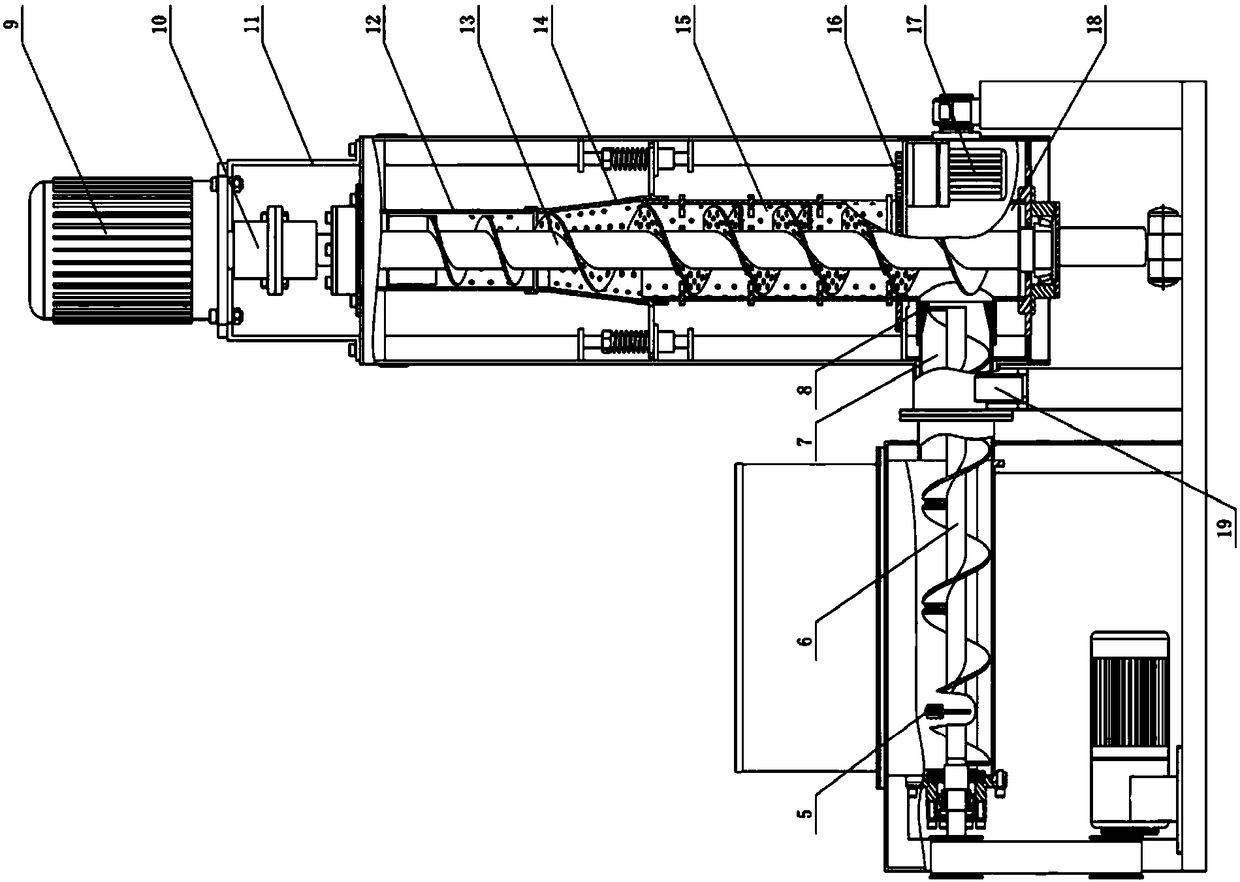

[0029] The staggered dispersing screw barrel pair of the sorting pulping device is an embodiment of the present invention. In the dispersion pulping screw ( Figure 4 ) staggered spiral dispersing section, outer drum with screen drum ( Figure 5 ), fluctuation ring ( Figure 6 ) and the hydraulic adjustment mechanism to realize the separation and treatment of organic waste.

[0030] Figure 4Pulping auger for sorting. The method of welding the spiral blade and the mandrel is adopted. According to the function, it is divided into three areas: 1. Interlaced and dispersed spiral section; 2. Variable-diameter screw extrusion section; 3. Equal-diameter spiral conveying section. The total length of the spiral from the sorting feed inlet to 1 / 3-1 / 2 from the feed inlet is a staggered dispersing helical section, and the staggered dispersing helical section is two helical blades with a pitch of S arranged alternately, and the helical blades have apertures of For 8MM sieve holes, t...

Embodiment 2

[0036] Figure 7 is an embodiment of the present invention. The variable-diameter screw extrusion section conveys the material from the equal-diameter screw conveying section into the screw groove. The screw blade of the variable-diameter screw extrusion section has a sieve hole with a diameter of 8MM, and the depth of the screw groove of the screw blade decreases evenly. On a conical surface, the maximum depth of the screw groove is the same as the depth of the screw groove of the dispersion pulping spiral, and the minimum depth of the screw groove is the same as the depth of the screw groove of the equal-diameter spiral conveying section. The variable-diameter helical section accounts for between 1 / 5 and 1 / 3 of the length of the entire sorting helix, and the depth of the screw groove at the end of the variable-diameter helical section is 55%-65% of the depth of the initial screw groove.

[0037] In the variable-diameter spiral section, under the joint action of the variable...

Embodiment 3

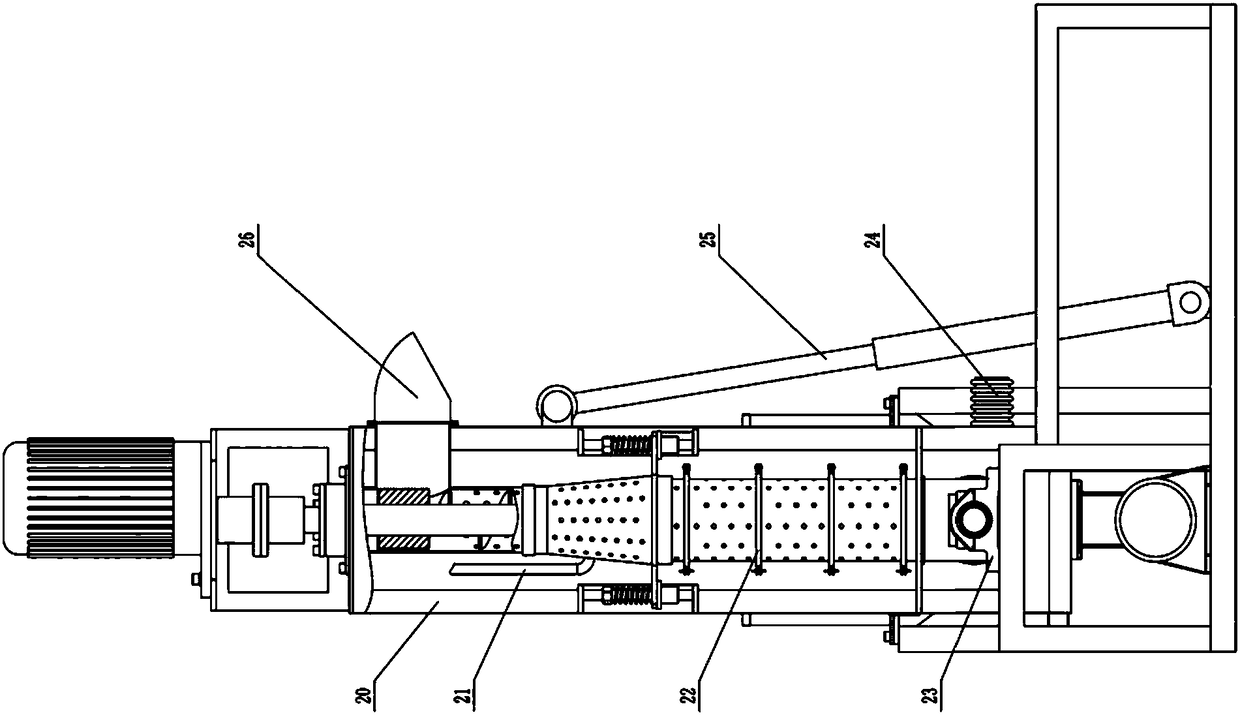

[0041] Figure 9 is an embodiment of the present invention. The connection structure between the mixing and crushing device (I) and the sorting and pulping device (II) is Figure 9 . The discharge cylinder (7) of the mixing and crushing device (I) is inserted into the feed cylinder (18) of the sorting and pulping device (II). ) between the feeding cylinders (18) form a groove cavity, and the fine particles in the garbage enter the inside of the groove during operation to form a self-sealing and reduce the leakage of liquid during operation.

[0042] The end of the discharge cylinder (7) of the mixing and crushing device (I) is welded with an inner cone ring (8), which forms a spiral pair with the variable-diameter spiral section of the mixing and crushing screw (6) at this position, and the spiral pair of this section increases during operation. The conveying pressure can avoid garbage backflow caused by the sorting and pulping screw (13) of the sorting and pulping device (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com