Widely-applicable high-efficiency nondestructive method for repairing heavy metal polluted farmland in situ

An in-situ remediation and heavy metal technology, which is applied in the field of contaminated soil remediation, can solve the problems of easy corrosion and decomposition of straw ropes, safety risks, and changes in soil micro-ecological systems, so as to achieve safe and reliable implementation, low investment and operation costs, and increased soil pollution. The effect of fertility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

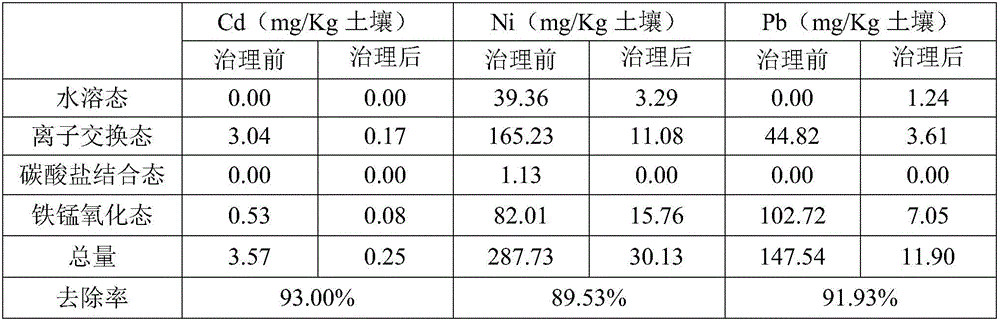

Embodiment 1

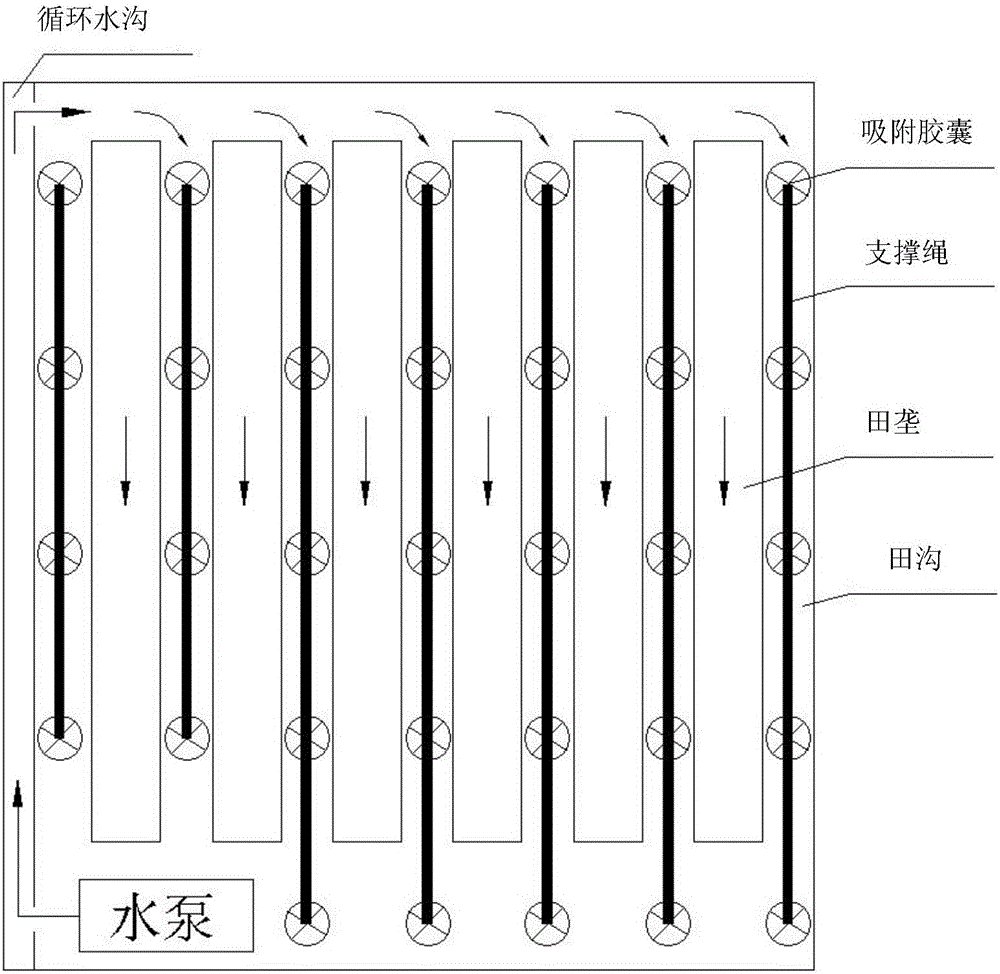

[0032] Step 1: plow the surface soil of the farmland polluted by heavy metals to a depth of 30 cm, and build a field ridge with a depth of 30 cm, a width of 40 cm, and a field ditch of 30 cm;

[0033] Step 2: Use local water sources as irrigation water, use phosphoric acid to adjust the pH value of the irrigation water to 4.0, use it to irrigate the polluted farmland, submerge the field ridges to a height of 10 cm, and soak for 3 days;

[0034] Step 3: Arrange a movable adsorption module every 2m in each field ditch. The movable adsorption module is composed of a support rope, a fixed ring, and a detachable adsorption capsule. The detachable adsorption capsule has a particle size of 0.5mm 、Specific surface area≥1000m 2 Composed of / g activated carbon and gauze bag, the detachable adsorption capsule is installed at a depth of 15cm from the water surface, and at the same time starts the internal circulation of the soaking water in the farmland, so that the soaking water is in a ...

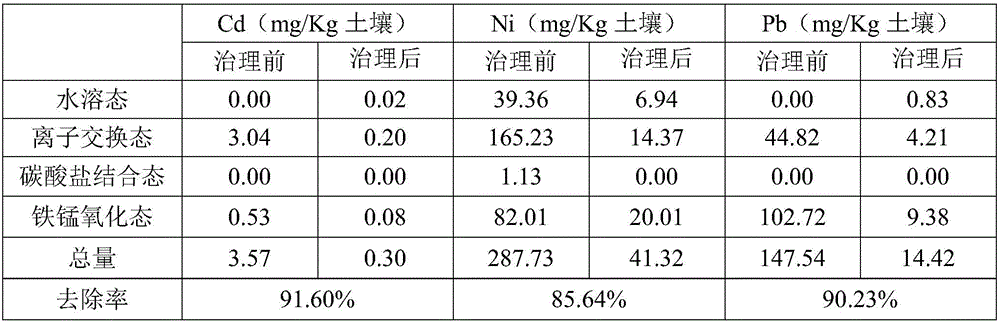

Embodiment 2

[0040] Step 1: plow the surface soil of the farmland polluted by heavy metals to a depth of 35 cm, and build a field ridge with a depth of 30 cm, a width of 40 cm, and a field ditch of 30 cm;

[0041] Step 2: Use local water sources as irrigation water, use phosphoric acid to adjust the pH value of the irrigation water to 5.0, use it to irrigate the polluted farmland, submerge the field ridges to a height of 10 cm, and soak for 5 days;

[0042] Step 3: Arrange a movable adsorption module every 2m in each field ditch. The movable adsorption module is composed of a support rope, a fixed ring, and a detachable adsorption capsule. The detachable adsorption capsule consists of a particle size of 1mm, Specific surface area ≥ 1500m 2 / g Activated carbon fiber and gauze bag. The detachable adsorption capsule is installed at a depth of 15cm from the water surface. At the same time, the internal circulation of the soaking water in the farmland is started to make the soaking water flow s...

Embodiment 3

[0048] Step 1. Plow the surface soil of the farmland polluted by heavy metals to a depth of 40 cm, and build a field ridge with a depth of 30 cm, a width of 40 cm, and a field ditch of 30 cm;

[0049] Step 2: Use local water sources as irrigation water, use phosphoric acid to adjust the pH value of the irrigation water to 6.0, use it to irrigate the polluted farmland, submerge the field ridges to a height of 10 cm, and soak for 7 days;

[0050] Step 3: Arrange a movable adsorption module every 2m in each field ditch. The movable adsorption module is composed of a support rope, a fixed ring, and a detachable adsorption capsule. The detachable adsorption capsule consists of a particle size of 3mm, Specific surface area ≥ 500m 2 Composed of / g activated carbon and gauze bag, the detachable adsorption capsule is installed at a depth of 15cm from the water surface, and at the same time starts the internal circulation of the soaking water in the farmland, so that the soaking water i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com