Novel amorphous master alloy ingot continuous casting system and application method thereof

An amorphous master alloy and amorphous alloy technology, which is applied in the field of continuous casting systems, can solve the problems of unsuitable promotion and use, high construction cost and operating cost, and poor controllability, and achieves the advantages of avoiding surface oxidation, low equipment cost and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

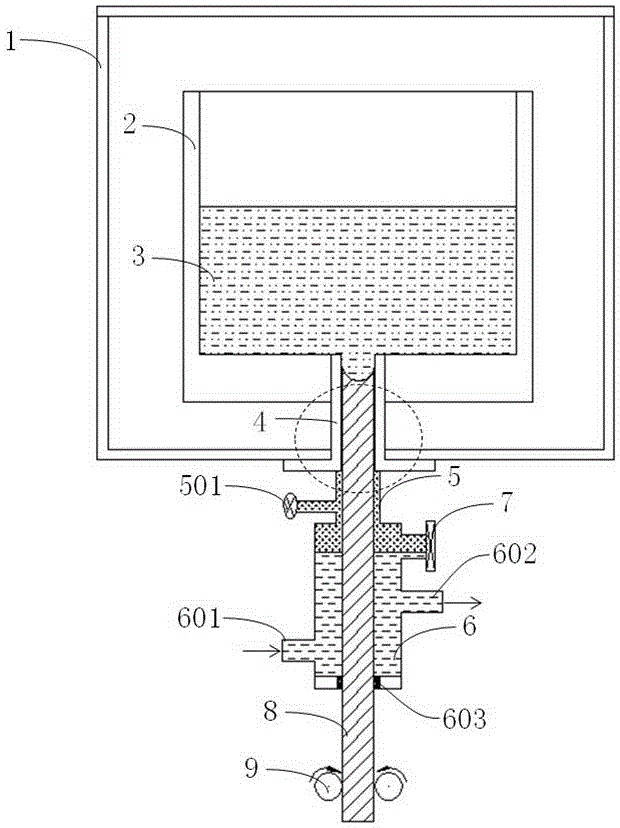

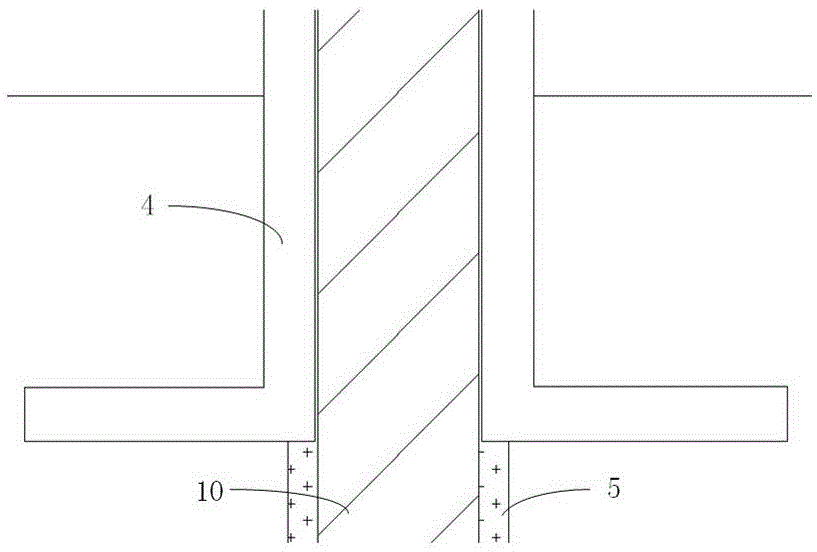

[0026] The vertical continuous casting system for amorphous master alloy ingot in this embodiment is as attached figure 1 As shown, it includes a melting device 2 , a water-cooled crystallizer 4 , a draw bar 8 and a draw device 9 . The melting material device can adopt the melting material device for amorphous alloy in the prior art, and the traction device can use rollers or other mechanical devices that can realize traction.

[0027] The molten material device 2 is arranged inside the vacuum chamber 1, and the amorphous alloy casting process is vacuum casting or inert atmosphere casting. The vacuum chamber 1 can adopt the structure of a vacuum melting chamber for ordinary amorphous alloy casting, such as the top or side of the vacuum chamber. Open and close for filling amorphous smelting raw materials, vacuum valves, inert gas valves, safety valves...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com