Gantry moving beam type vertical turning-milling combined machining center

A composite machining center and vertical lathe technology, applied in the direction of manufacturing tools and other manufacturing equipment/tools, can solve the problem that the processing capacity of embedded chips cannot support advanced network applications, and achieve high cost performance, good dynamic performance, and processing The effect of strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

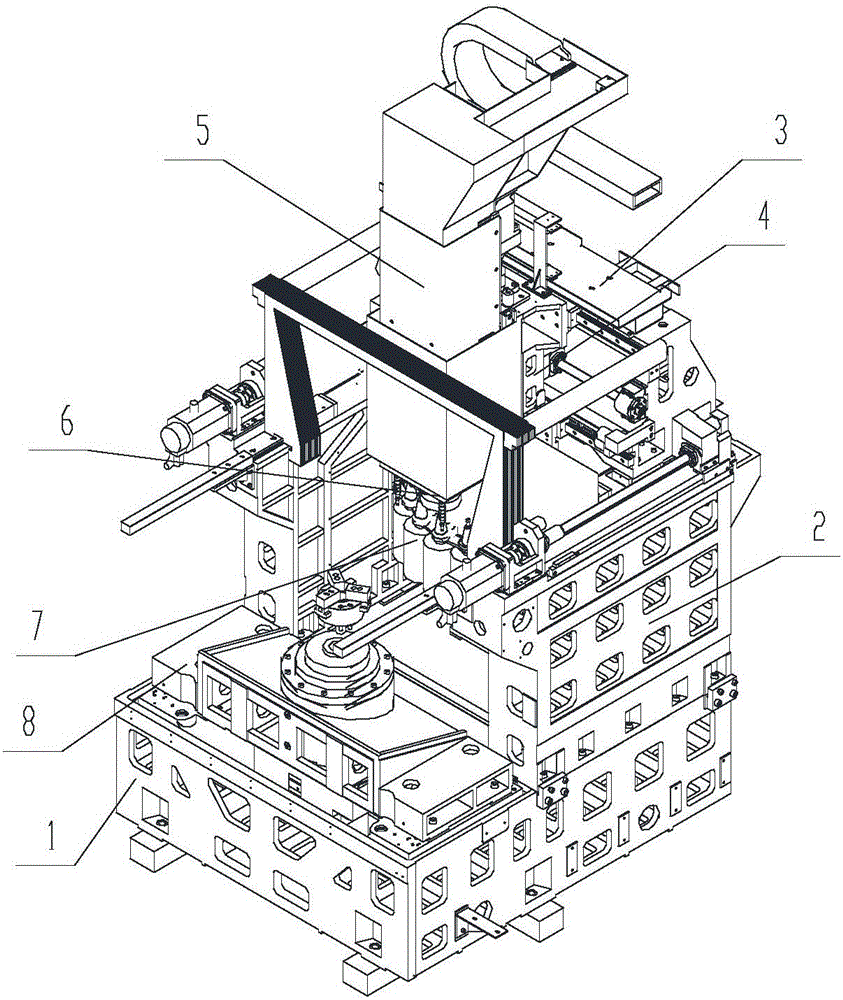

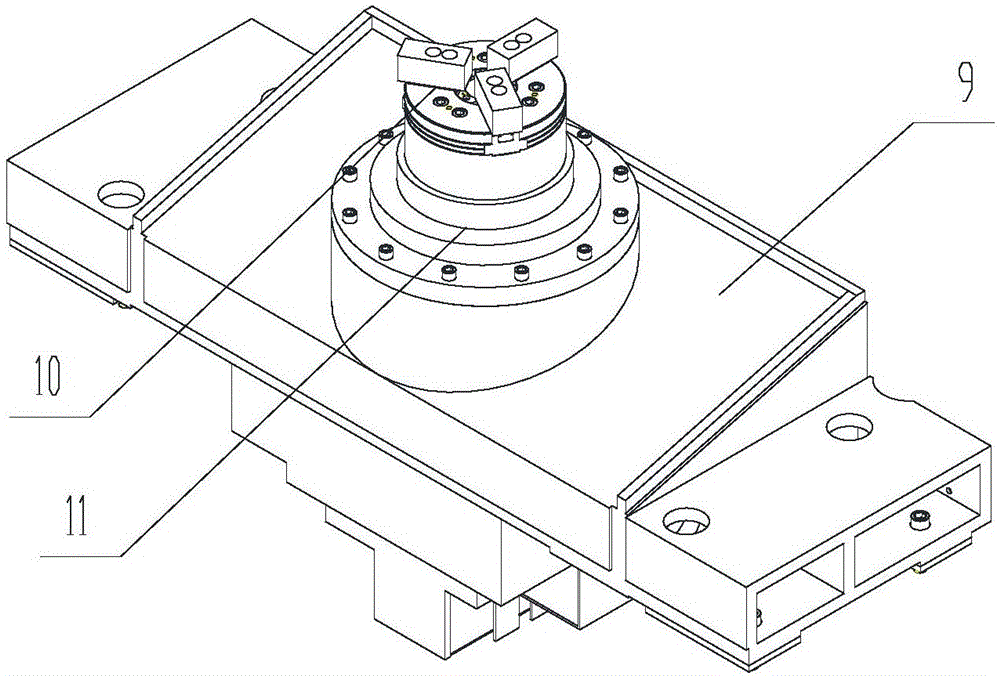

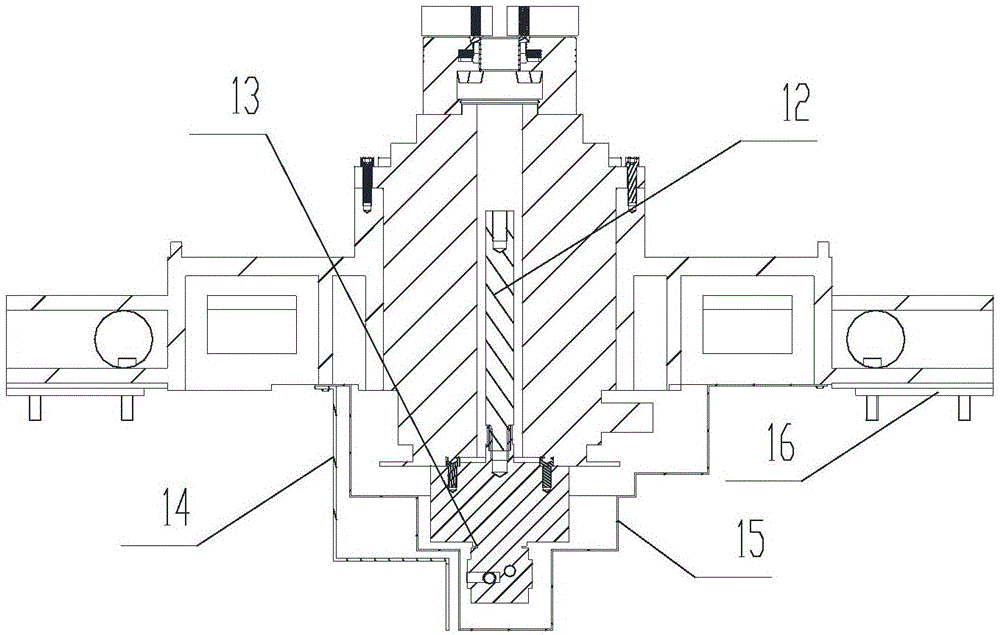

[0024] A gantry moving beam type vertical turning and milling compound machining center of the present invention, the structure and implementation scheme are as follows Figure 1-2-a , 2-b, including the setting of the gantry moving beam machine tool, which is characterized in that: i5CNC, the underlying motion control system based on the Internet, adopts the EtherCAT bus protocol to control PLC and motor drive. Carry out communication, accept instructions or send machine tool information; structural modularization: the vertical turning spindle unit 8 is fixed on the front horizontal surface of the gantry moving beam frame bed 1; the gantry moving beam frame setting includes the bed 1, left and right columns 2 is fixed on the bed 1, the crossbeam 3 is fixed on the guide rail slider and moves forward and backward on the column 2 in the Y axis, the sliding saddle 4 connected with the headstock 5 is fixed on the guide rail slider and moves on the crossbeam 3 in the X axis left and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com