Environment-friendly chitosan compound containing corrosion and scale inhibitor and preparation method thereof

A technology of corrosion and scale inhibitor, chitosan, applied in the field of phosphorus-free scale and corrosion inhibitor and its preparation, can solve the problems of difficult biodegradation, high price, polluted water resources, etc., achieves good biodegradability, avoids The effect of eutrophication and improving water saving rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

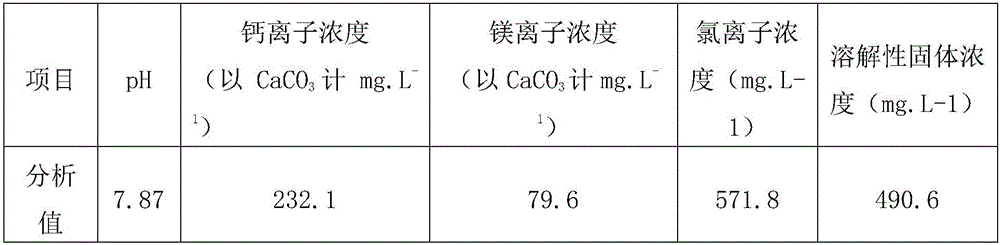

Method used

Image

Examples

preparation example Construction

[0025] Preparation of chitosan-containing compound corrosion and scale inhibitors, the method is as follows:

[0026] Add chitosan, polyaspartic acid or polyepoxysuccinic acid into distilled water in sequence, heat in a water bath to 80°C, add dilute hydrochloric acid with a mass concentration of 1% to 2%, stir at constant temperature for 1 to 2 hours, and let stand. After the temperature drops to normal temperature, a chitosan compound is obtained, wherein the mass ratio of chitosan to polyaspartic acid or polyepoxysuccinic acid is 1:2.7~1:3.4, and the mass concentration of chitosan to 1 The mass ratio of %~2% dilute hydrochloric acid is 1:1~1:1.5;

[0027] Each material is taken according to the following composition mass percentage: chitosan compound 35% ~ 40%, acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer 4% ~ 6%, polyacrylate 6% ~ 10%, sodium gluconate 10% ~ 15%, soluble zinc salt 3% ~ 5%, the rest is distilled water;

[0028] Add acrylic acid-2-acryl...

Embodiment 1

[0031] Prepare the chitosan compound according to the preparation method of the above-mentioned chitosan compound, wherein: chitosan 8g, polyaspartic acid 27g, water bath heating temperature 80 ℃, dilute hydrochloric acid mass concentration 1%, consumption 10g, constant temperature Stirring time 1h,

[0032] Prepare 100g of chitosan-containing compound corrosion and scale inhibitors according to the above method, the amount of each raw material: chitosan-polyaspartic acid compound 35g, acrylic acid-2-acrylamide-2-methylpropanesulfonate Acid copolymer (solid content is 40%) 4g, sodium polyacrylate 9g, sodium gluconate 12g, Zn(NO 3 ) 2 .6H 2 O 5g, the rest is distilled water.

Embodiment 2

[0034] Prepare the chitosan compound according to the preparation method of the above-mentioned chitosan compound: wherein: chitosan 9g, polyepoxysuccinic acid 27g, water bath heating temperature 80°C, dilute hydrochloric acid mass concentration 1%, consumption 10g, constant temperature Stirring time 1h,

[0035] Prepare 100g of chitosan-containing compound corrosion and scale inhibitors, raw materials: chitosan-polyepoxysuccinic acid compound 36g, acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer (solid Content is 40%) 5g, sodium polyacrylate 8g, sodium gluconate 13g, Zn(NO 3 ) 2 .6H 2 O 4g, the rest is distilled water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com