Oilfield reinjection water comprehensive treatment system

A technology for oil field re-injection and comprehensive treatment, applied in the field of oil-field re-injection water comprehensive treatment system, can solve the problems of bacteria clogging the oil layer, incomplete sterilization, rising water injection pressure, etc., to improve the degree of automation, solve incomplete sterilization, and simplify oil removal. the effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

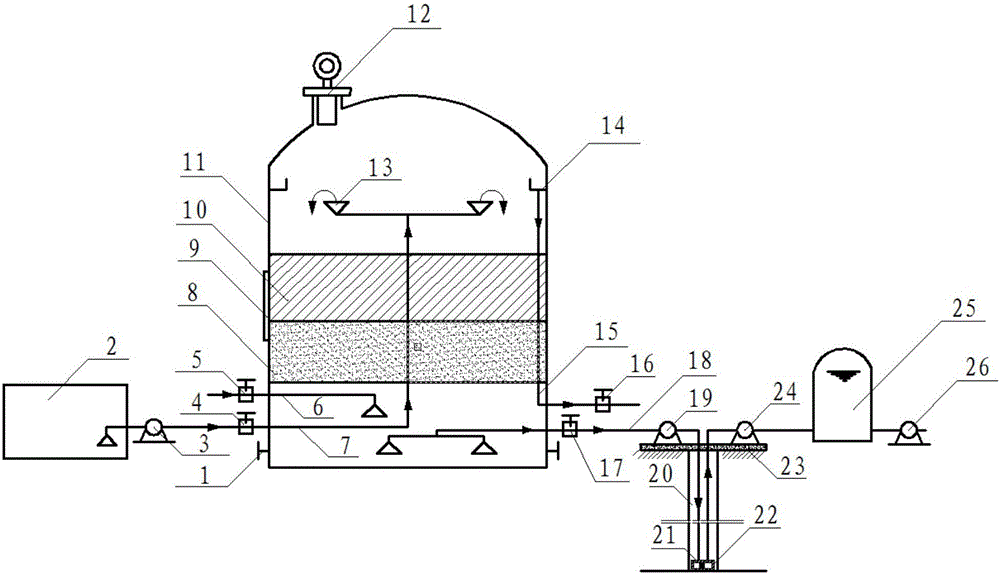

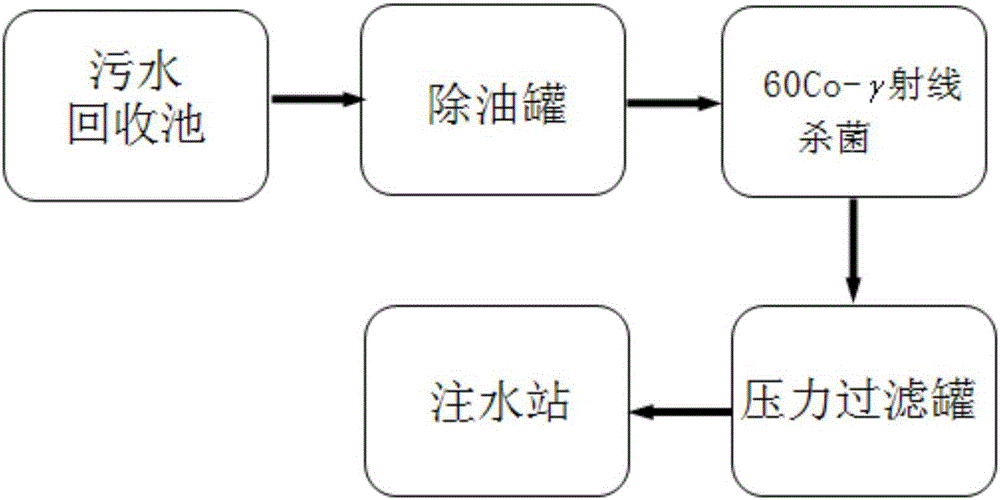

[0026] Such as figure 1 As shown, a comprehensive oilfield reinjection water treatment system includes three parts: sterilization, oil removal and filtration. The sterilizing part mainly includes a radioactive source 21 , a stainless steel sealing device 22 and a concrete sealing device 23 . Put the radioactive source 60Co into the abandoned oil well 20, open the gate valve 17 after the oil removal is completed, and inject the sewage into the abandoned oil well 20 through the water delivery pump 19 along the water delivery pipeline 18, using 60Co-γ rays with high energy and strong penetrating power The characteristics of sterilization. For the sulfate-reducing bacteria, saprophytic bacteria, rust bacteria and other bacteria that have certain drug resistance and are difficult to kill mainly in oilfield sewage, the irradiation metering can be ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com