Modified nano TiO2/Ag/bamboo charcoal composite material and method for killing microorganisms in medical sewage by virtue of same

A composite material and bamboo charcoal technology, applied in the field of TiO2/Ag/bamboo charcoal composite materials, can solve the problems of serious bio-fouling and pungent odor in the pipe network

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

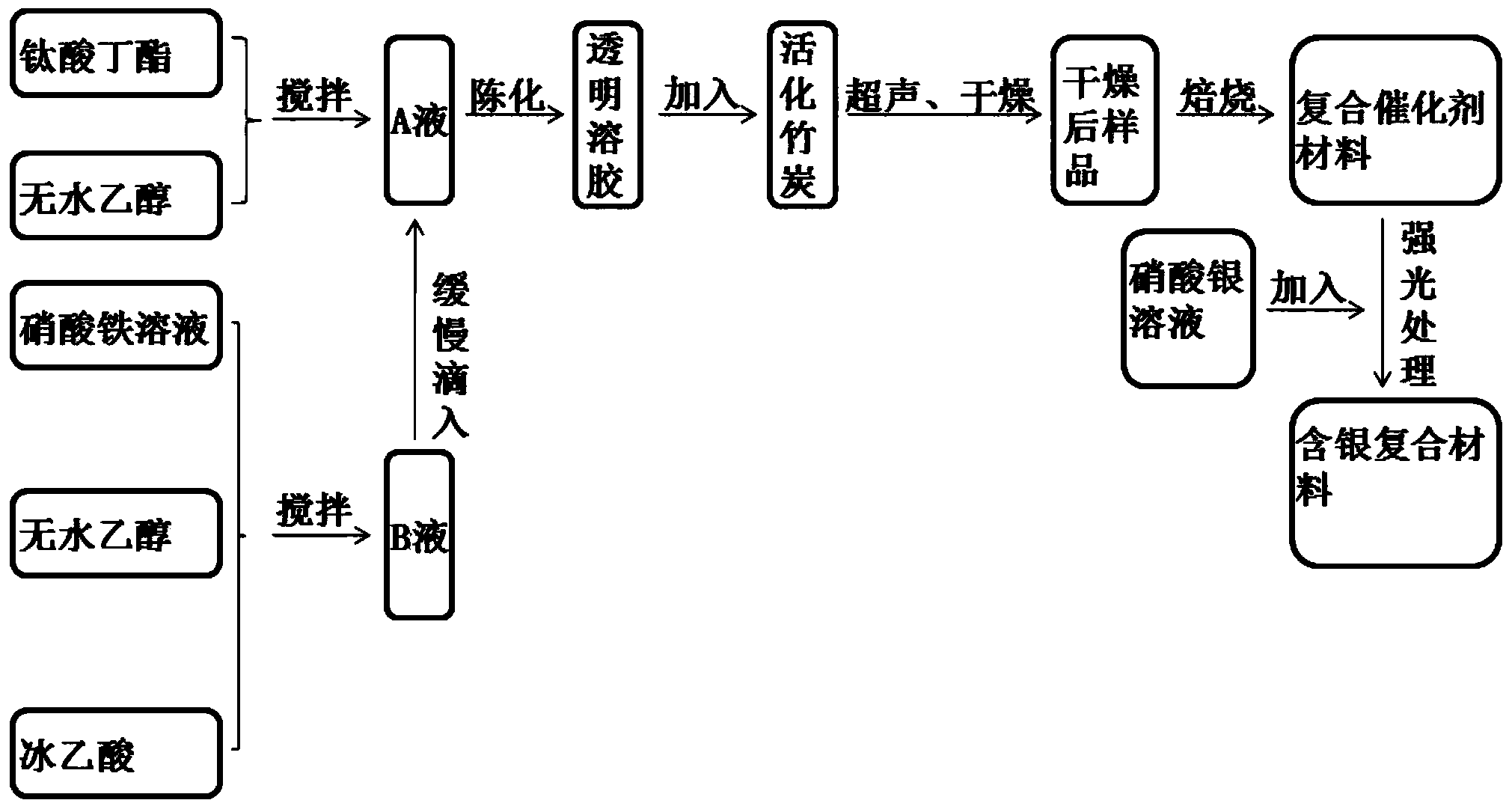

Method used

Image

Examples

Embodiment 1

[0028] Example 1: 1. Add 1 part of butyl titanate and 3 parts of absolute ethanol by volume into a dry clean container and stir evenly to make A solution, then add 0.3 parts of nitric acid with a concentration of 0.21mol / L Add iron solution, 1 part of absolute ethanol, and 0.5 part of glacial acetic acid by volume into a dry container and stir evenly to make solution B; ②, slowly add solution B to solution A, stir while adding, and dropwise complete Then continue to stir for about 30 minutes to form a stable sol, and age the sol for about 5 hours for use; ③. After putting the bamboo charcoal into the aged sol prepared in step ②, treat it under ultrasonic conditions with a frequency of 45KHz at 32°C for 1 hour to dilute the sol. The gel enters the internal pores of the bamboo charcoal, and then the bamboo charcoal is taken out and dried at 80°C; ④, the bamboo charcoal is taken out of the drying oven in step ③ and roasted in a tube furnace at 550°C for 3 hours in a nitrogen atmos...

Embodiment 2

[0029] Example 2: 1. Add 1 part of butyl titanate and 3 parts of absolute ethanol by volume into a dry container and stir evenly to make A solution, then add 0.4 parts of nitric acid with a concentration of 0.21mol / L Add iron solution, 1 part of absolute ethanol, and 0.5 part of glacial acetic acid by volume into a dry container and stir evenly to make solution B; ②, slowly add solution B to solution A, stir while adding, and dropwise complete Then continue to stir for about 30 minutes to form a stable sol, and age the sol for about 5 hours for use; ③. After putting the bamboo charcoal into the aged sol prepared in step ②, treat it under ultrasonic conditions with a frequency of 45KHz at 32°C for 1 hour to dilute the sol. The gel enters the internal pores of the bamboo charcoal, and then the bamboo charcoal is taken out and dried at 80°C; ④, the bamboo charcoal is taken out of the drying oven in step ③ and roasted in a tube furnace at 550°C for 3 hours in a nitrogen atmosphere ...

Embodiment 3

[0030] Example 3: 1. Add 1 part of butyl titanate and 3 parts of absolute ethanol by volume into a dry clean container and stir evenly to make A solution, then add 0.4 parts of nitric acid with a concentration of 0.21mol / L Add iron solution, 1 part of absolute ethanol, and 0.5 part of glacial acetic acid by volume into a dry container and stir evenly to make solution B; ②, slowly add solution B to solution A, stir while adding, and dropwise complete Then continue to stir for about 30 minutes to form a stable sol, and age the sol for about 5 hours for use; ③. After putting the bamboo charcoal into the aged sol prepared in step ②, treat it under ultrasonic conditions with a frequency of 45KHz at 32°C for 1 hour to dilute the sol. The gel enters the internal pores of the bamboo charcoal, and then the bamboo charcoal is taken out and dried at 80°C; ④, the bamboo charcoal is taken out of the drying oven in step ③ and roasted in a tube furnace at 550°C for 3 hours in a nitrogen atmos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com