Method and system for treating high-ammonia nitrogen photovoltaic waste water containing cadmium and thiourea

A waste water treatment, high ammonia nitrogen technology, applied in the treatment process, high ammonia nitrogen, cadmium and thiourea photovoltaic wastewater treatment field, to achieve the effect of reducing operating costs, large environmental benefits, and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

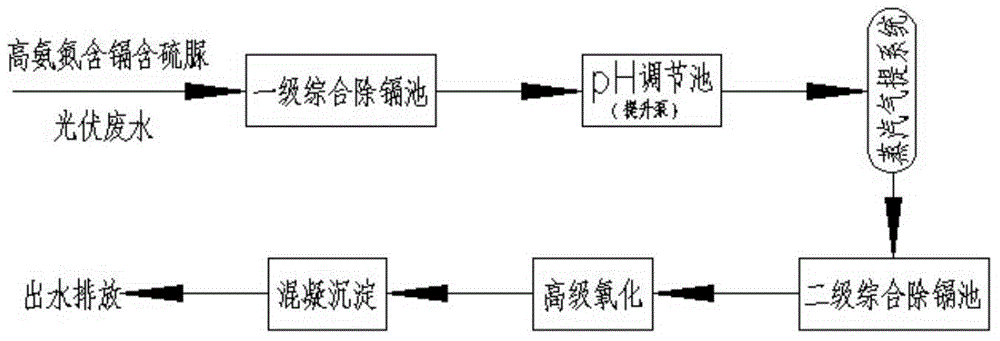

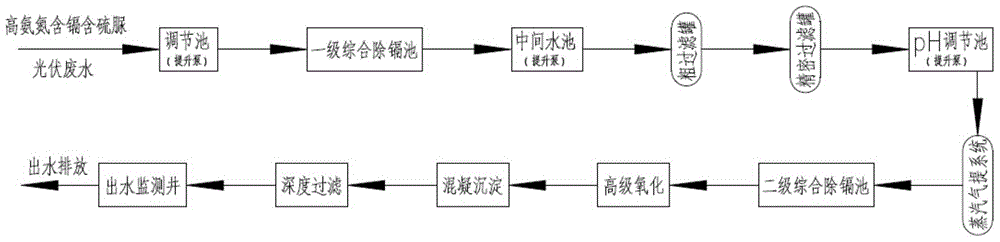

[0031] In the actual application process, the present invention adopts such as figure 1 , 2 The shown process is realized, and the high ammonia nitrogen-containing cadmium-containing thiourea photovoltaic wastewater treatment system involved in the present invention includes a first-level comprehensive cadmium removal tank, a pH adjustment tank, a steam stripping system, a second-level comprehensive cadmium removal tank, and advanced oxidation Pool, coagulation sedimentation tank; the first-level comprehensive cadmium removal tank, pH adjustment tank, second-level comprehensive cadmium removal tank, advanced oxidation tank, and coagulation-sedimentation tank are respectively equipped with chemical dosing systems. The first-level comprehensive cadmium removal pool is also equipped with a sedimentation tank, an intermediate pool, a coarse filter tank, and a precision filter tank; the steam stripping system includes an ammonia distillation stripper, an ammonia absorption tower, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com