Polypeptide amino acid plant growth stimulant and preparation method thereof

A plant growth and amino acid technology, which is applied in the field of polypeptide amino acid plant growth stimulant and its preparation, can solve the problems of single amino acid component and poor absorption and utilization rate of plants, so as to improve harvest quality, increase photosynthetic rate and photosynthetic intensity, The effect of high fruit setting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

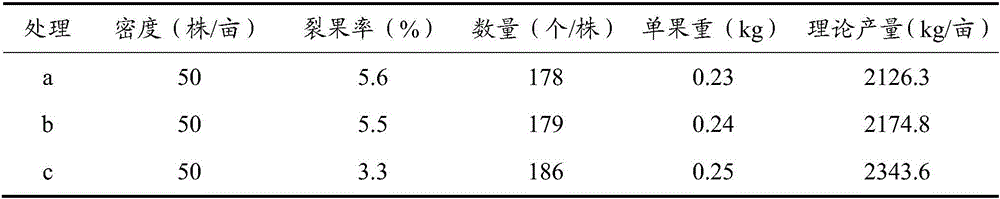

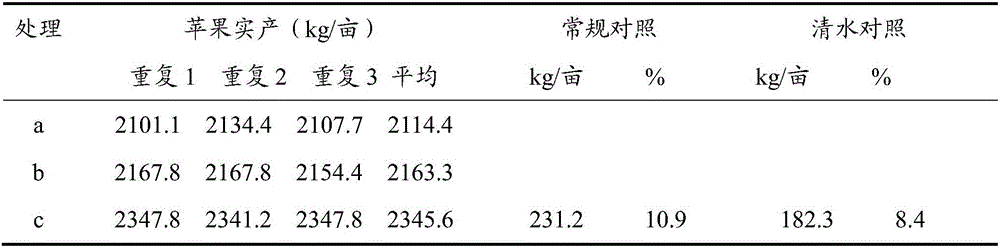

Examples

Embodiment 1

[0022] The polypeptide amino acid plant growth stimulant in Example 1 of the present invention is mainly made of the following raw materials in parts by weight: 150 parts of free amino acids, 350 parts of small molecule active peptides, 80 parts of organic nitrogen, 5 parts of urea nitrogen, and 260 parts of organic carbon parts and 55 parts of other trace elements.

[0023] The preparation method of the polypeptide amino acid plant growth stimulant in the present embodiment 1 is specifically: 500 parts of polypeptide amino acids with a mass percentage concentration of 55%, including 150 parts of free amino acids and 350 parts of small molecule active peptides, and 80 parts of organic nitrogen , 5 parts of urea nitrogen, 260 parts of organic carbon, 55 parts of medium and trace elements are mixed, then add water that is 100 parts by weight and stir and chelate in the reactor for 6 hours, and the chelating temperature is 80 ° C; then step 1 The product prepared in was cooled to...

Embodiment 2

[0025] The polypeptide amino acid plant growth stimulant of Example 2 of the present invention is mainly made of the following raw materials in parts by weight: 150 parts of free amino acids, 350 parts of small molecule active peptides, 80 parts of organic nitrogen, 5 parts of urea nitrogen, and 260 parts of organic carbon parts and 55 parts of other trace elements.

[0026] The preparation method of the polypeptide amino acid plant growth stimulant of the present embodiment 2 is specifically: 500 parts of polypeptide amino acids with a mass percentage concentration of 55%, including 150 parts of free amino acids and 350 parts of small molecule active peptides, and 80 parts of organic nitrogen , 5 parts of urea nitrogen, 260 parts of organic carbon, 55 parts of medium and trace elements are mixed, then add water that is 100 parts by weight and stir and chelate in the reactor for 6 hours, and the chelating temperature is 80 ° C; then step 1 The product prepared in was cooled to...

Embodiment 3

[0028] The polypeptide amino acid plant growth stimulant of Example 3 of the present invention is mainly made of the following raw materials in parts by weight: 150 parts of free amino acids, 350 parts of small molecule active peptides, 80 parts of organic nitrogen, 5 parts of urea nitrogen, and 260 parts of organic carbon parts and 55 parts of other trace elements.

[0029] The preparation method of the polypeptide amino acid plant growth stimulant of the present embodiment 3 is specifically: 500 parts of polypeptide amino acids with a mass percentage concentration of 55%, including 150 parts of free amino acids and 350 parts of small molecule active peptides, and 80 parts of organic nitrogen , 5 parts of urea nitrogen, 260 parts of organic carbon, 55 parts of medium and trace elements are mixed, then add water that is 100 parts by weight and stir and chelate in the reactor for 6 hours, and the chelating temperature is 80 ° C; then step 1 The product prepared in was cooled to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com