Synthetic technology of 3,5-dichloro-2-pentanone

A synthesis process and technology for mixtures, which are applied in the preparation of heterocyclic compounds, separation/purification of carbonyl compounds, organic chemistry, etc., can solve the problems of reducing the reaction yield and increasing the difficulty of treatment of three wastes, etc., and achieve high purity and yield. The effect of chlorination reaction time and conversion rate improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

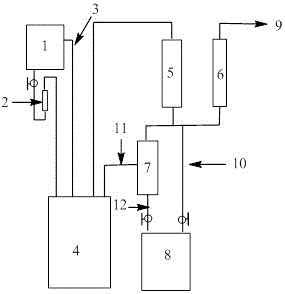

[0025] Add 4.8 Kg of glacial acetic acid (99.5%) and 21.3 Kg of concentrated hydrochloric acid (31%) in the 50 L reactor 4, start stirring and mix thoroughly and heat up to 70 o C; 12 Kg (purity 98%) α-chloro-α-acetyl-γ-butyrolactone and 292 g methyltrioctylammonium chloride are fully mixed in a mixer and then pumped into the premix liquid head tank 1 , the flow rate is controlled by the dropping flowmeter 2 to drop the premixed liquid into the reaction kettle; after the dropping, the temperature rises to 78-80 o C. After stirring for 30 minutes, turn on the vacuum to -0.08 MPa for steam distillation under reduced pressure, and keep the internal temperature at 78-80 o C, steam distilled for 2.5 hours until the distillate does not contain products; drop the balance pipe 3 to maintain the pressure balance in the premixed liquid head tank 1 and the reactor 4, so that the premixed liquid can flow smoothly into the reactor 4 Inside; the balance pipe 10 is used to maintain the pres...

Embodiment 2

[0027] Except that the acid added in the reactor was changed to 25.5 Kg concentrated hydrochloric acid (31%), all the others were the same as in Example 1. After the reaction was finished, 9.7 Kg of colorless 3,5-dichloro-2-pentanone was obtained with a purity of 94.8%. Yield 82.0%.

Embodiment 3

[0029] Except that the phase transfer catalyst was benzyltriethylammonium chloride, the others were the same as in Example 1. After the reaction, the purity of the final product 3,5-dichloro-2-pentanone was 95.2%, and the yield was 88.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com