High-weather-resistance heat-reflection steel plate coil metal paint and preparation method thereof

A metal coating and heat reflection technology, applied in the direction of reflection/signal paint, coating, etc., can solve problems such as improper use of dispersants, influence of coating film fluidity, and reduction of coating film weather resistance, and achieve good heat reflection performance, excellent High weather resistance, surface temperature reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

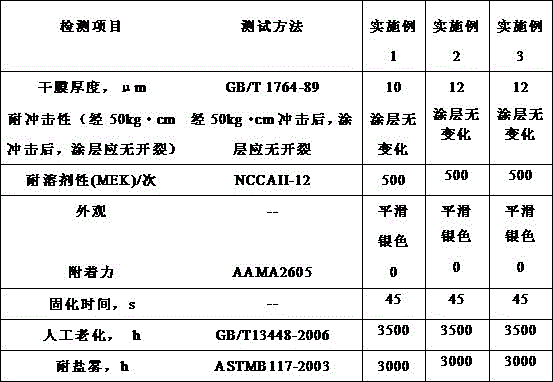

Examples

Embodiment 1

[0034] PVDF resin 24%,

[0035] Acrylic resin 8%,

[0036] Polymethyl methacrylate 2.5%,

[0037] Aluminum powder 10.2%,

[0038] Isophorone 40%,

[0039] Diisobutyl ketone 10%,

[0040] Defoamer 0.3%,

[0041] Silane coupling agent 0.6%,

[0042] UV ultraviolet absorber 0.4%,

[0043] Leveling aid 0.4%,

[0044] Titanium dioxide 3%,

[0045] Alignment agent 0.6%.

[0046] The preparation method of the highly weather-resistant heat-reflecting steel coil metal coating, the steps are as follows: according to the ratio, acrylic resin, polymethyl methacrylate and aluminum powder are stirred and dispersed at 3000r / min, and then organic Solvent ball milling until the slurry fineness is less than 10μm, then add PVDF resin, defoamer, silane coupling agent, UV ultraviolet absorber, leveling aid, titanium dioxide and alignment agent, stir and disperse evenly at 3000r / min to obtain The highly weatherable heat reflective steel sheet metal coating.

Embodiment 2

[0048] PVDF resin 22%,

[0049] Acrylic resin 10%,

[0050] Polymethyl methacrylate 3%,

[0051] Aluminum powder 11%,

[0052] Isophorone 42%

[0053] Xylene 5.3%

[0054] Defoamer 0.4%,

[0055] Silane coupling agent 0.6%,

[0056] UV ultraviolet absorber 0.5%,

[0057] Leveling aid 0.5%,

[0058] Titanium dioxide 4%,

[0059] Alignment agent 0.7%.

[0060] The preparation method of the highly weather-resistant heat-reflecting steel coil metal coating, the steps are as follows: according to the ratio, acrylic resin, polymethyl methacrylate and aluminum powder are stirred and dispersed at 3000r / min, and then organic Solvent ball milling until the slurry fineness is less than 10μm, then add PVDF resin, defoamer, silane coupling agent, UV ultraviolet absorber, leveling aid, titanium dioxide and alignment agent, stir and disperse evenly at 3000r / min to obtain The highly weatherable heat reflective steel sheet metal coating.

Embodiment 3

[0062] PVDF resin 20%,

[0063] Acrylic resin 10.5%,

[0064] Polymethyl methacrylate 5%,

[0065] Aluminum powder 12%,

[0066] Isophorone 45%,

[0067] Defoamer 0.4%,

[0068] Silane coupling agent 0.5%,

[0069] UV ultraviolet absorber 0.6%,

[0070] Leveling aid 0.5%,

[0071] Titanium dioxide 5%,

[0072] Alignment agent 0.5%.

[0073]The preparation method of the highly weather-resistant heat-reflecting steel coil metal coating, the steps are as follows: according to the ratio, acrylic resin, polymethyl methacrylate and aluminum powder are stirred and dispersed at 3000r / min, and then organic Solvent ball milling until the slurry fineness is less than 10μm, then add PVDF resin, defoamer, silane coupling agent, UV ultraviolet absorber, leveling aid, titanium dioxide and alignment agent, stir and disperse evenly at 3000r / min to obtain The highly weatherable heat reflective steel sheet metal coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com