Novel water-based epoxy anticorrosive coating and preparation method thereof

An anti-corrosion coating, water-based epoxy technology, applied in the field of coatings, can solve the problems of coating anti-corrosion performance, failure to meet product coating requirements, performance gap and other problems, achieve high market application value, good environmental protection performance, and improve anti-corrosion performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

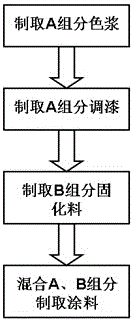

[0016] figure 1 It is a process step chart of the preparation method of the new water-based epoxy anti-corrosion coating in the embodiment of the present invention; the anti-corrosion coating is prepared by mixing the A-component letdown and the B-component curing material, and the preparation method includes the following steps: a) preparing Take component A color paste, b) prepare component A letdown paint, c) prepare component B curing material, d) mix components A and B to prepare paint.

[0017] The new water-based epoxy anti-corrosion coating mentioned in the present invention is based on water-based epoxy resin emulsion and water-based modified amine curing agent, and adopts suitable film-forming aids, dispersants, defoamers, leveling agents and other auxiliary agents. The active anti-rust pigment compounded by aluminum tripolyphosphate and zinc phosphate is selected for preparation. The prepared water-based epoxy anti-corrosion coating has good environmental performanc...

Embodiment 1

[0019] The specific preparation method is as follows:

[0020] a) Preparation of component A color paste, the specific preparation process is as follows: firstly weigh 2.2% iron oxide red, 10% rutile titanium dioxide, 20% precipitated barium sulfate, 3.1% mica powder, 14% active antirust pigment, 0.4% BYK-110 wetting and dispersing agent, 0.3% BYK-034 defoamer, 50% deionized water; then wetting and dispersing agent, defoaming agent and deionized water Mix to obtain the auxiliary agent mixture; then put iron oxide red, rutile titanium dioxide, precipitated barium sulfate, mica powder and active antirust pigment into the auxiliary agent mixture, and grind it to a fineness of less than 30um by a sand mill to obtain A component color paste.

[0021] b) Preparation of component A letdown, the specific preparation process is as follows: firstly weigh 45% of component A color paste, 50% of water-based epoxy resin emulsion, and 4.5% of ethylene glycol monobutyl ether film-forming aid...

Embodiment 2

[0025] The specific preparation method is as follows:

[0026] a) Preparation of component A color paste, the specific preparation process is as follows: firstly weigh 2.8% iron oxide red, 12% rutile titanium dioxide, 22% precipitated barium sulfate, 4.1% mica powder, 16% active antirust pigment, 0.6% BYK-110 wetting and dispersing agent, 0.5% BYK-034 defoamer, 42% deionized water; then wetting and dispersing agent, defoaming agent and deionized water Mix to obtain the auxiliary agent mixture; then put iron oxide red, rutile titanium dioxide, precipitated barium sulfate, mica powder and active antirust pigment into the auxiliary agent mixture, and grind it to a fineness of less than 30um by a sand mill to obtain A component color paste.

[0027] b) Preparation of component A letdown, the specific preparation process is as follows: firstly weigh 48% of component A color paste, 45% of water-based epoxy resin emulsion, and 6% of ethylene glycol monobutyl ether film-forming aid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com