Tobacco aroma enhancing and moisture retaining agent and preparation method and application thereof

A technology of flavoring agent and moisturizing flavoring agent, which is applied in the directions of tobacco, tobacco preparation, application, etc., to achieve the effects of good compatibility, improving moisturizing effect and product safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

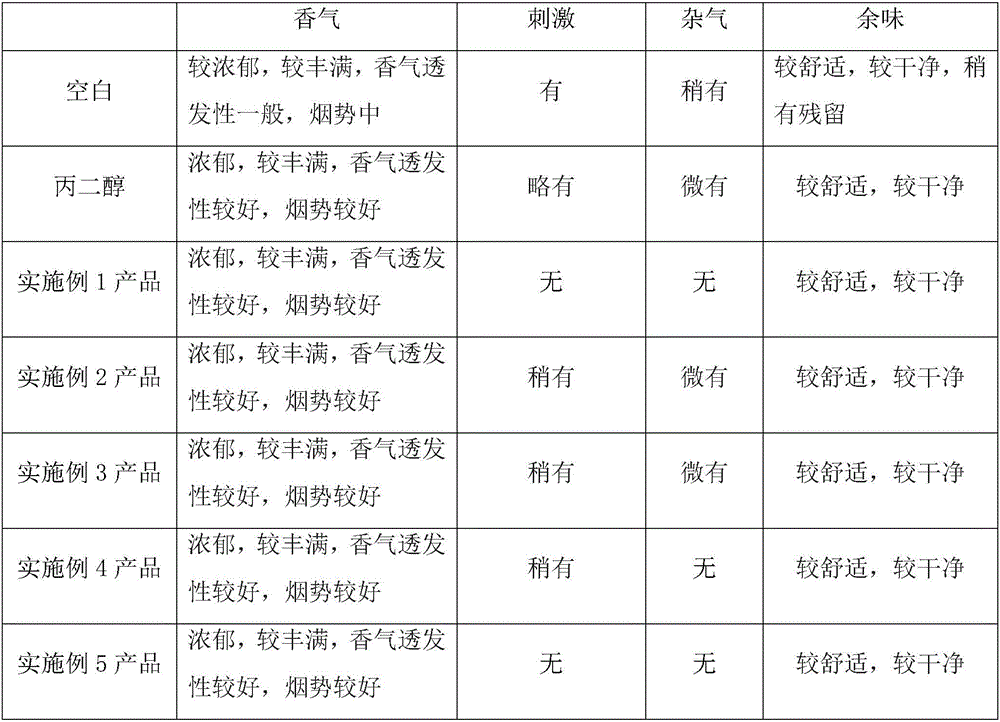

Examples

Embodiment 1

[0024] A tobacco moisturizing and flavoring agent of the present invention is prepared from the following raw materials in parts by weight: 2 parts of carotenoids, 5 parts of phenolic compounds, 12 parts of emulsifiers, 40 parts of polyols, 0.5 parts of antioxidants, deionized 40.5 parts of water.

[0025] (1) Mix 35g of propylene glycol, 5g of inositol, 2g of carotenoids, and 0.5g of butylated hydroxyanisole at a stirring speed of 1000rpm, heat up to 60°C, and stir at a constant temperature for 20min;

[0026] (2) Add 5 g of chlorogenic acid to 40.5 g of deionized water, heat to 60 ° C and stir to dissolve, then add the solution prepared in step (1), and simultaneously add 5 g of polysorbate-80 and 7 g of sucrose ester to mix the emulsifier uniformly, Set the stirring speed at 2000rpm, the temperature at 60°C, and stir at a constant temperature for 40 minutes to fully dissolve the mixture under the action of strong shear force and achieve emulsification and homogeneity;

[0...

Embodiment 2

[0030] A tobacco moisturizing and flavoring agent of the present invention is prepared from the following raw materials in parts by weight: 0.5 parts of carotenoids, 10 parts of phenolic compounds, 5 parts of emulsifiers, 30 parts of polyols, 0.1 parts of antioxidants, deionized 54.4 parts of water.

[0031] (1) Mix 20g of propylene glycol, 2g of inositol, 8g of glycerol, 0.5g of carotenoids, and 0.1g of dibutyl hydroxytoluene at a stirring speed of 1500rpm, raise the temperature to 40°C, and stir at a constant temperature for 30min;

[0032] (2) Add 5g of chlorogenic acid and 5g of caffeic acid to 54.4g of deionized water, heat to 40°C and stir to dissolve, then add the solution prepared in step (1), and add 2g of polysorbate-80 and 3g of alkyl glucoside at the same time to mix Uniform emulsifier, set the stirring speed at 2500rpm, the temperature at 40°C, and stir at a constant temperature for 50 minutes to make the mixture fully dissolve under the action of strong shear for...

Embodiment 3

[0036] A tobacco moisturizing and flavoring agent of the present invention is prepared from the following raw materials in parts by weight: 1 part of carotenoids, 8 parts of phenolic compounds, 10 parts of emulsifiers, 50 parts of polyols, 0.2 parts of antioxidants, deionized 31 parts of water;

[0037] (1) Mix 50g propylene glycol, 1g carotenoid, 0.1g butyl hydroxyanisole, and 0.1g propyl gallate, stir at 800rpm, heat up to 50°C, and stir at constant temperature for 40min;

[0038] (2) Add 5g of chlorogenic acid and 3g of scopoletin to 40.5g of deionized water, heat to 50°C and stir to dissolve, then add the solution prepared in step (1), and simultaneously add 2g of polysorbate-80, 3g of sucrose ester, 5g of Glyceryl monostearate is an emulsifier evenly mixed, the stirring speed is set to 2200rpm, the temperature is 50°C, and the constant temperature is stirred for 60 minutes, so that the mixture is fully dissolved under the action of strong shear force, and emulsification a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com