ldmos device and its manufacturing method

A device manufacturing method, N-type technology, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problem that the P-type layer is difficult to meet at the same time, to achieve reduced impact ionization, low conduction resistance, and improved The effect of on-state breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

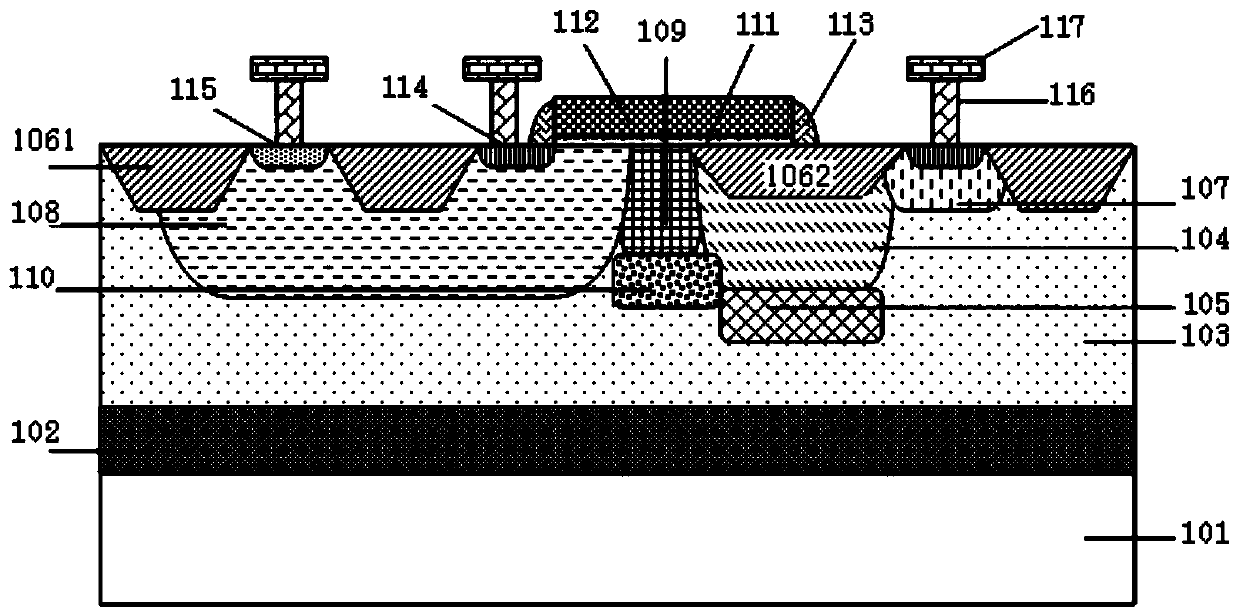

[0062] Such as figure 1 As shown, the LDMOS device includes a P-type epitaxial layer 103, an N well 107, a P well 108, a first N-type drift region 104, a first P-type layer 105, a second N-type drift region 109, a second P-type layer 110, Gate oxide layer 111, gate polysilicon 112;

[0063] The P-well 108, the second N-type drift region 109, the first N-type drift region 104, and the N-well 107 are successively formed on the upper part of the P-type epitaxial layer 103 from left to right;

[0064] The gate oxide layer 111 is formed on the right part of the P well 108, the left part of the first N-type drift region 104 and above the second N-type drift region 109;

[0065] The gate polysilicon 112 is formed on the gate oxide layer 111;

[0066] The second N-type drift region 109 is shallower than the first N-type drift region 104;

[0067] The second P-type layer 110 and the first P-type layer 105 are formed in the P-type epitaxial layer 103;

[0068] The second P-type laye...

Embodiment 2

[0076] Based on the LDMOS device of the first embodiment, the N-type doping concentration of the first N-type drift region 104 and the second N-type drift region 109 is smaller than the N-type doping concentration of the N-well 107 .

[0077] Preferably, the N-type doping concentration of the first N-type drift region 104 and the second N-type drift region 109 is within 1e 16 / cm 3 to 5e 16 / cm 3 between.

[0078] In the LDMOS device of the second embodiment, the N-type drift region is lightly doped, which can increase the breakdown voltage of the PN junction between the N well 107 and the P well 108 .

Embodiment 3

[0080] Based on the LDMOS device of Embodiment 1, a field oxide 1062 in a field oxide region is formed above the first N-type drift region 104;

[0081] The gate oxide layer 111 is formed on the right part of the P well 108, the left part of the field oxide region 1062 and above the second N-type drift region 109;

[0082] There is a trench isolation region isolation oxide 1061 between the N-type heavily doped region 114 and the P-type heavily doped region 115 formed on the P well 108;

[0083] The trench isolation region isolation oxide 1061 is deeper than the field oxide region 1062 .

[0084] The LDMOS device of Embodiment 3 can be integrated in the BCD process, and the N-type drift region and the P-type layer are implanted on the bottom of the ultra-shallow trench in the field oxygen region using the mask plate etched by the ultra-shallow trench, and then the conventional isolation is formed. Trench, because the ultra-shallow trench isolation is carried out separately fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com