Method for preparing lithium ion battery cathode material wrapped and modified by Li-lacked material

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of reduced capacity, increased battery polarization, and inability to form dopant bodies, etc., and achieve low Li/Ni mixed discharge , high charge and discharge efficiency, and excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

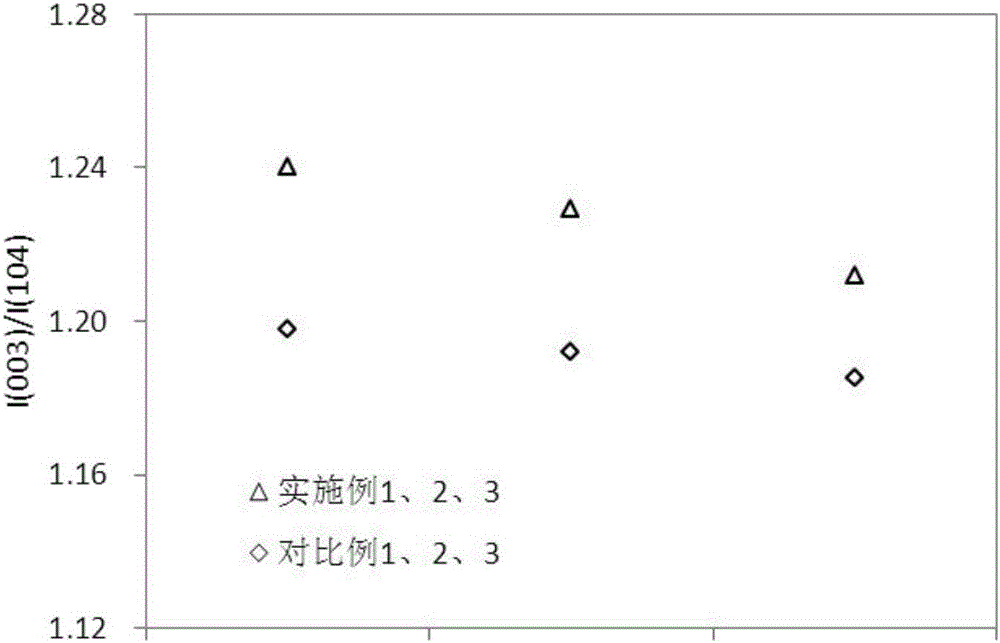

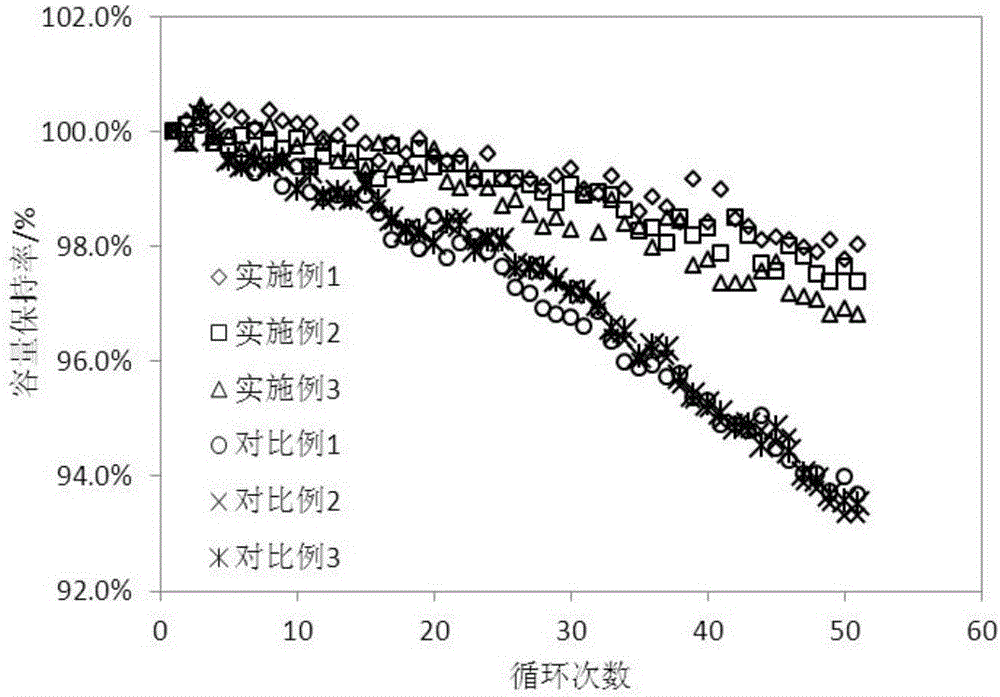

[0031] Example 1: Li 0.98 CoO 2 Coating modified Li(Ni 0.5 co 0.18 mn 0.3 al 0.02 )O 2 Preparation of cathode materials

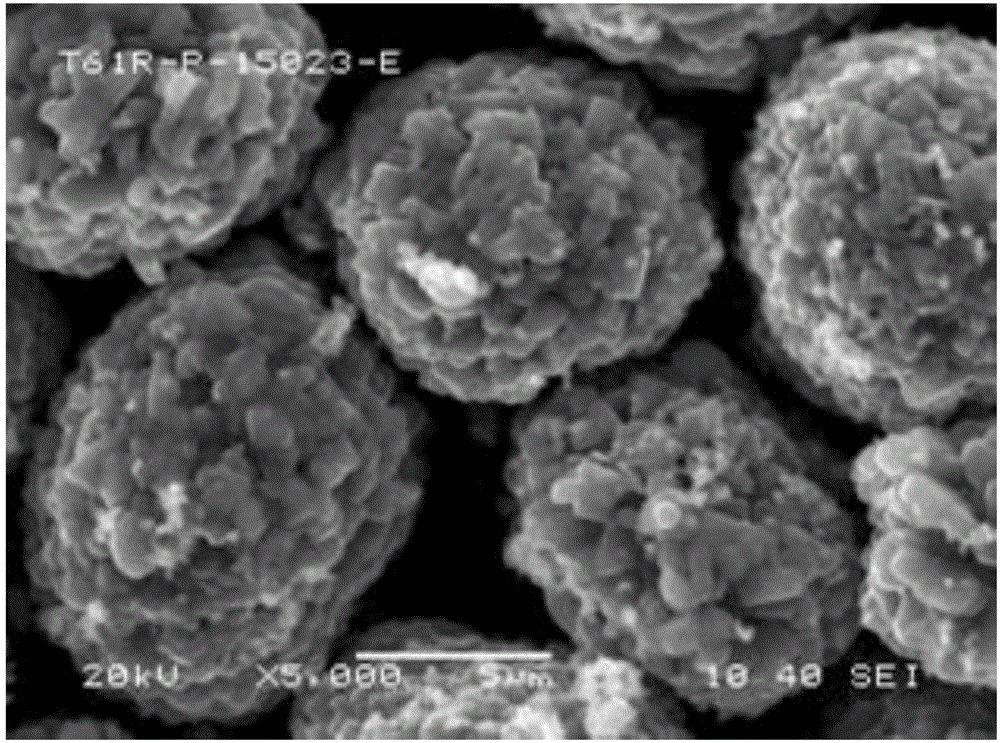

[0032] a kind of like figure 1 The Li-deficient state material of the present invention is shown as a lithium-ion battery positive electrode material coated with modification, and its preparation method specifically includes the following steps:

[0033] (1) 50.0g Ni 0.5 co 0.2 mn 0.3 (OH) 2 , 21.1g Li 2 CO 3 , 0.2g Al 2 o 3 Ball milling and mixing at 1000rpm for 3h, and then sintering at 850°C for 12h to prepare the positive active material matrix; the molecular formula of the positive active material matrix is Li(Ni 0.5 co 0.18 mn 0.3 al 0.02 )O 2 ;

[0034] (2) 20.0g Co 3 o 4 and 8.9g Li 2 CO 3 Mixed by ball milling at 1200rpm for 3h, and then sintered at 1030°C for 15h to obtain the Li-deficient active material; the molecular formula of the Li-deficient active material is Li 0.98 CoO 2 ;

[0035] (3) Weigh the positive elect...

Embodiment 2

[0037] Example 2: Li 0.97 (Ni 0.5 co 0.2 mn 0.3 )O 2 Coating modified Li(Ni 0.6 co 0.2 mn 0.2 )O 2 Preparation of cathode material

[0038] A lithium-ion battery positive electrode material coated with a Li-deficient state material of the present invention, and its preparation method specifically includes the following steps:

[0039] (1) 50.0g Ni 0.6 co 0.2 mn 0.2 (OH) 2 , 21.0g Li 2 CO 3 Mixed by ball milling at 1000rpm for 3h, and then sintered at 840°C for 10h to obtain the positive active material matrix; the molecular formula of the positive active material matrix is Li(Ni 0.6 co 0.2 mn 0.2 )O 2 ;

[0040] (2) 20.0g Ni 0.5 co 0.2 mn 0.3 (OH) 2 and 7.8g Li 2 CO 3 Mixed by ball milling at 1200rpm for 3h, and then sintered at 870°C for 10h to obtain the Li-deficient active material; the molecular formula of the Li-deficient active material is Li 0.97 (Ni 0.5 co 0.2 mn 0.3 )O 2 ;

[0041] (3) Weigh the positive electrode active material matrix...

Embodiment 3

[0043] Example 3: Li 0.96 (Ni 0.6 co 0.2 mn 0.2 )O 2 Coating modified Li(Ni 0.8 co 0.1 mn 0.1 )O 2 Preparation of cathode material

[0044] A lithium-ion battery positive electrode material coated with a Li-deficient state material of the present invention, and its preparation method specifically includes the following steps:

[0045] (1) 50.0g Ni 0.8 co 0.1 mn 0.1 (OH) 2 , 20.8g Li 2 CO 3 Ball milling and mixing at 1000rpm for 3h, and then sintering at 820°C for 10h to prepare the positive active material matrix; the molecular formula of the positive active material matrix is Li(Ni 0.8 co 0.1 mn 0.1 )O 2 ;

[0046] (2) 20.0g Ni 0.6 co 0.2 mn 0.2 (OH) 2 and 7.7g Li 2 CO 3Mixed by ball milling at 1200rpm for 3h, and then sintered at 860°C for 10h to obtain the Li-deficient active material; the molecular formula of the Li-deficient active material is Li 0.96 (Ni 0.6 co 0.2 mn 0.2 )O 2 ;

[0047] (3) Weigh the positive electrode active material mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com