A kind of preparation method of porous carbon matrix composite material

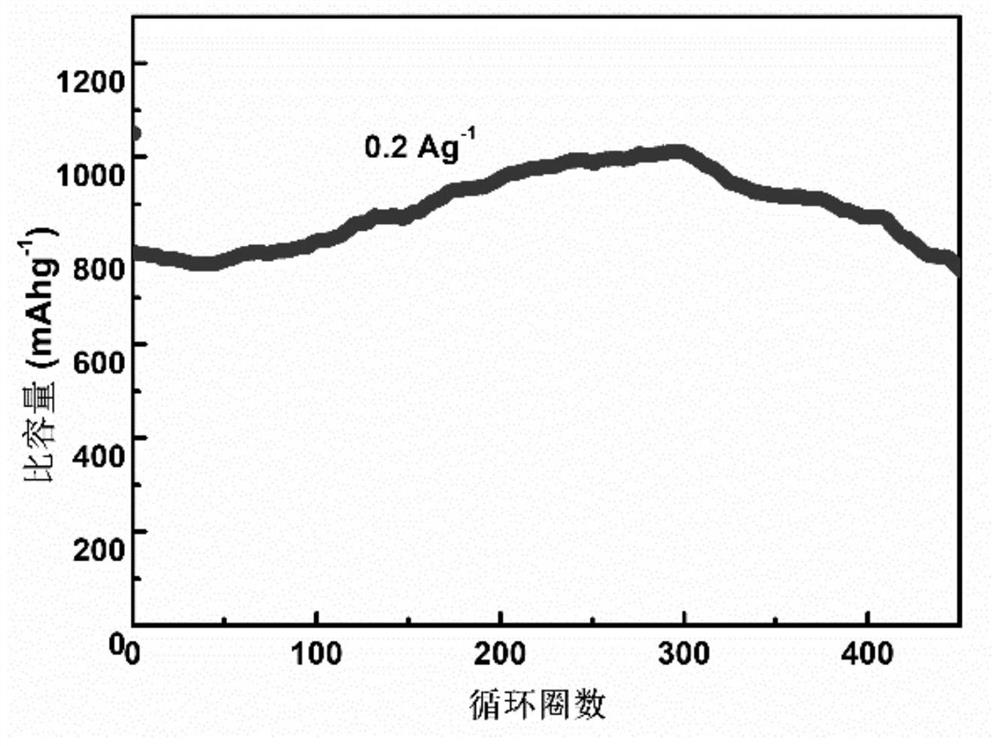

A composite material, porous carbon technology, applied in the preparation/purification of carbon, hybrid capacitor electrodes, structural parts, etc., can solve the problems of changing soil microbial diversity, complex preparation process, polluting the environment, etc. The effect of simple process flow and excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

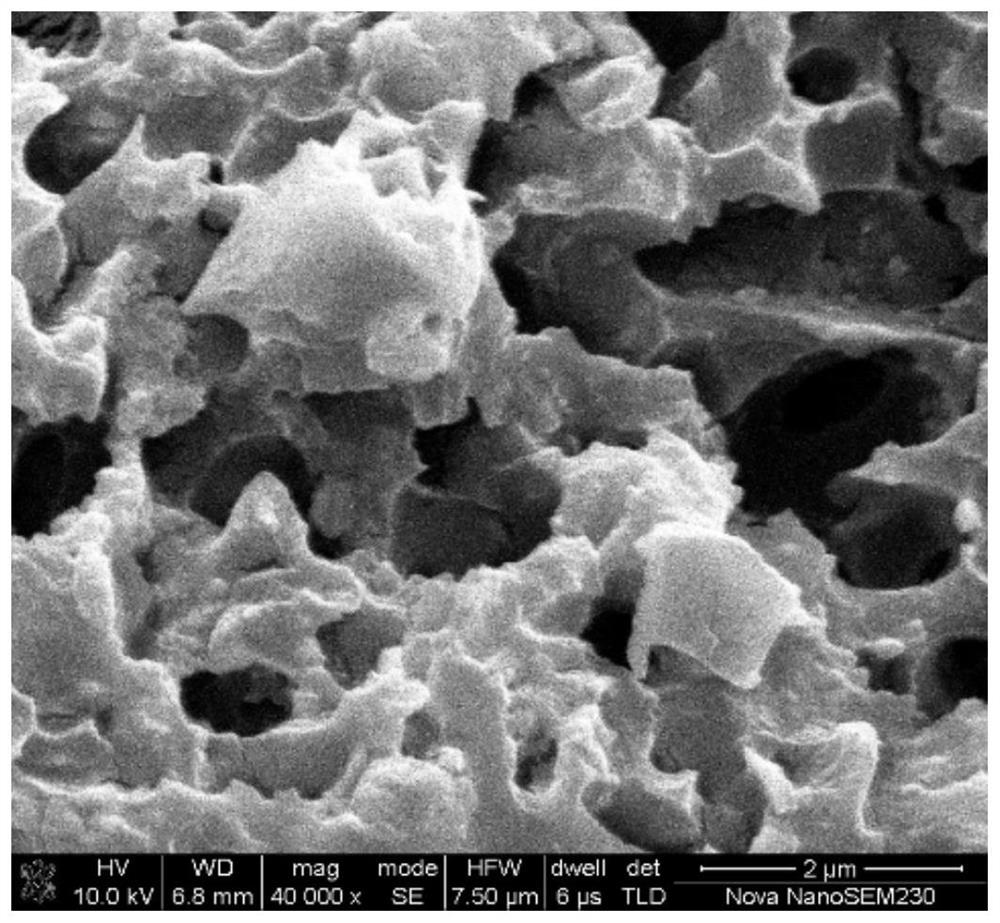

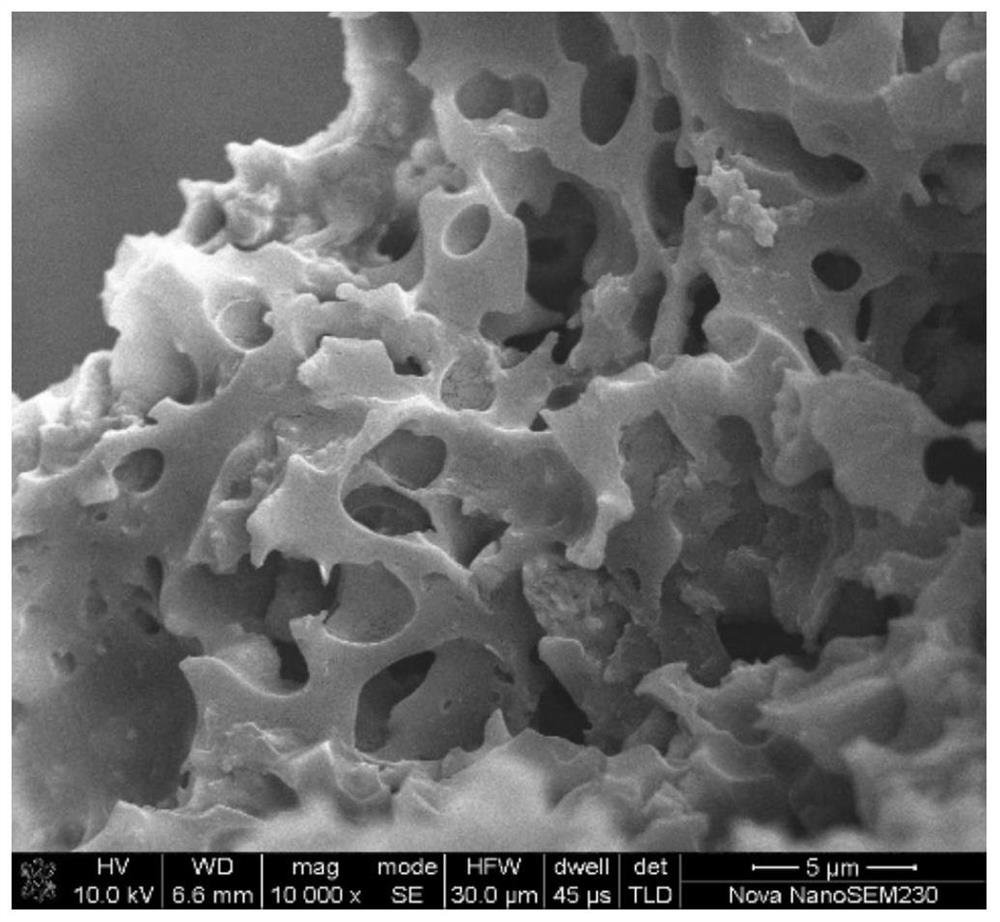

Image

Examples

Embodiment 1

[0036] The invention provides a method for preparing a porous carbon-based composite material, comprising the following steps:

[0037] (1) After drying 6g of oxytetracycline bacteria residue at 120°C for 24 hours, mix and stir with 8ml of deionized water to make a suspension of bacteria residue;

[0038] (2) Weigh 1.45g potassium hydroxide and dissolve in 5ml deionized water, weigh 0.3g potassium permanganate and dissolve in 5ml deionized water;

[0039] (3) Mix the lye prepared in step (2) with the suspension of bacterial residue, stir for 2 hours, after the cleavage reaction ends, remove impurities by filtration to obtain the bacterial residue solution, then add potassium permanganate solution dropwise and stir at 90°C until Evaporate to dryness to be solid, obtain solidified mixture;

[0040] (4) Place the solidified mixture in a muffle furnace with a nitrogen atmosphere, heat it to 900°C at 5°C / min and keep it warm for 2h, wash and dry the product with an aqueous ethanol...

Embodiment 2

[0043] The invention provides a method for preparing a porous carbon-based composite material, comprising the following steps:

[0044] (1) After drying 6g of penicillin bacteria residue at 120°C for 14h, mix and stir with 8ml of deionized water to make a suspension of bacteria residue;

[0045] (2) Weigh 1.3g of sodium hydroxide and dissolve in 5ml of deionized water, weigh 0.5g of nickel nitrate and dissolve in 5ml of deionized water;

[0046] (3) Mix the sodium hydroxide solution prepared in step (2) with the bacteria residue suspension, stir for 5 hours, after the cleavage reaction ends, remove impurities by filtration to obtain the bacteria residue solution, then add nickel nitrate solution dropwise, and stir at 90°C Until it is evaporated to dryness and becomes a solid state, a solidified mixture is obtained;

[0047](4) Place the solidified mixture in a muffle furnace with a nitrogen atmosphere, heat it to 800°C at 5°C / min and keep it warm for 2h, wash and dry the prod...

Embodiment 3

[0050] The invention provides a method for preparing a porous carbon-based composite material, comprising the following steps:

[0051] (1) After drying 6 g of erythromycin residue at 120° C. for 14 hours, mix and stir with 5 ml of deionized water to form a suspension of bacteria residue;

[0052] (2) Weigh 3g of potassium hydroxide and dissolve in 10ml of deionized water, weigh 0.3g of potassium permanganate and dissolve in 10ml of deionized water;

[0053] (3) Mix the potassium hydroxide solution prepared in step (2) with the bacterium residue suspension, stir for 3h, after the cleavage reaction ends, remove impurities by filtration to obtain the bacterium residue solution, then add potassium permanganate solution dropwise at 90°C Stir until evaporated to dryness to obtain a solidified mixture;

[0054] (4) Place the solidified mixture in a muffle furnace with a nitrogen atmosphere, heat it to 800°C at 5°C / min and keep it warm for 2h, wash and dry the product with methanol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com