A biochar-based cathode electrode sheet for lithium-air batteries

A technology of biochar and electrode sheets, which is applied to battery electrodes, fuel cell half-cells, secondary battery-type half-cells, circuits, etc., can solve the problems of not having the advantages of industrial-scale large-scale preparation, and achieve convenient Promote, improve the depth of utilization, and avoid the effect of technical routes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]Step 1. Mix Qigang and KOH according to the mass ratio of 5:3, then place it under a nitrogen atmosphere, and pyrolyze it at 900°C for 2 hours to obtain biochar; wherein, the yield of biochar prepared from Qigang as raw material is 30%;

[0035] Step 2. Grind the biochar obtained in step 1 into powder, then mix the biochar powder, acetylene black and PVDF evenly according to the mass ratio of 8:1:1 to obtain a slurry; then apply the slurry to the carbon Put it on the paper, dry it in a vacuum drying oven at 80°C, roll it, and cut it into pieces to obtain the positive electrode sheet of the lithium-air battery.

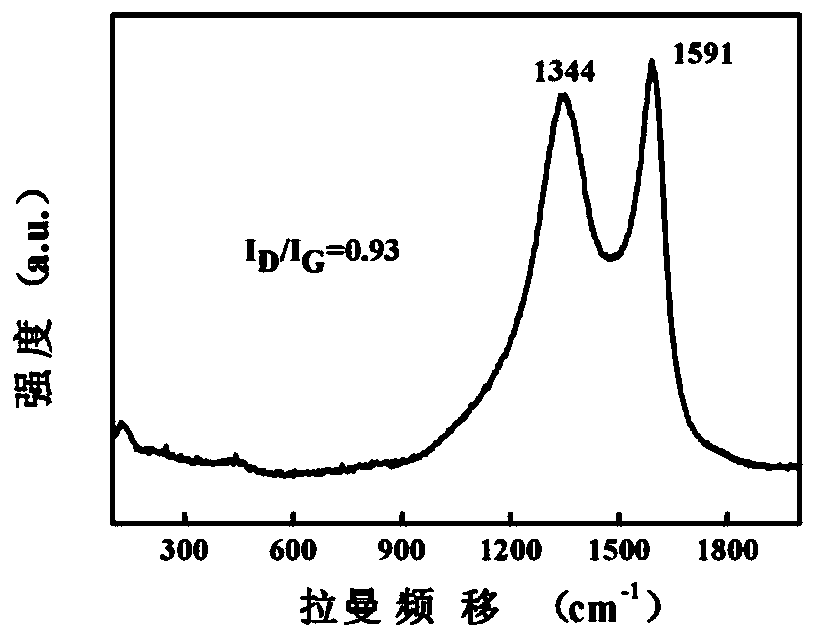

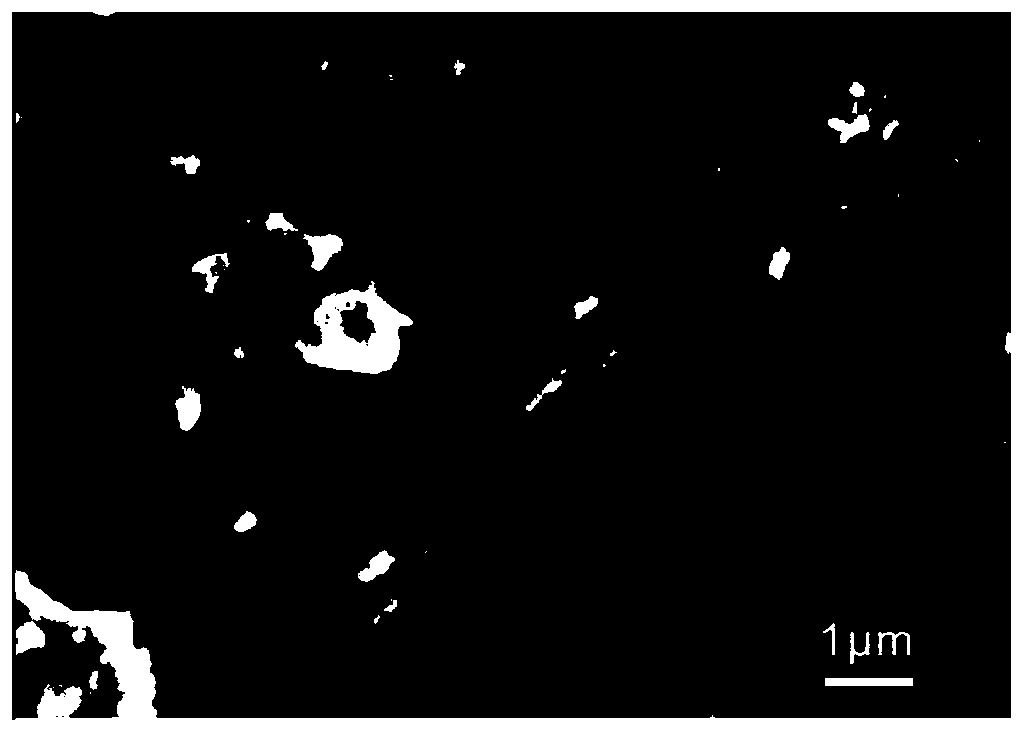

[0036] figure 1 It is the SEM image of the biochar prepared in step 1. It can be seen from the figure that the prepared biochar is a porous honeycomb structure, which is conducive to accommodating a large amount of air and increasing the discharge product (Li 2 o 2 ) storage space, providing more three-phase reaction interface, so it is beneficial to improve t...

Embodiment 2

[0046] Step 1. Mix Pennisetum hybrida and KOH at a mass ratio of 5:6, then place it under a nitrogen atmosphere, and pyrolyze it at 1200°C for 1 hour to obtain biochar; among them, biochar is prepared from Pennisetum hybrida as raw material The yield rate of 20%;

[0047] Step 2. Grind the biochar obtained in step 1 into powder, then mix the biochar powder, acetylene black and PVDF evenly according to the mass ratio of 8:1:1 to obtain a slurry; then apply the slurry to the carbon Put it on the paper, dry it in a vacuum drying oven at 80°C, roll it, and cut it into pieces to obtain the positive electrode sheet of the lithium-air battery.

[0048] From the SEM figure of the biochar prepared in this example, it can be seen that the prepared biochar is a porous structure, which is conducive to accommodating a large amount of oxygen (air), and increases the discharge product (Li 2 o 2 ) storage space, which provides more three-phase reaction interface, and thus is beneficial to i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com