Positive electrode catalyst for direct ethanol fuel cell and preparation method for positive electrode catalyst

A technology of fuel cells and catalysts, which is applied in the direction of battery electrodes, circuits, electrical components, etc., to achieve the effects of improving catalytic activity, simple and easy preparation methods, and easy industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

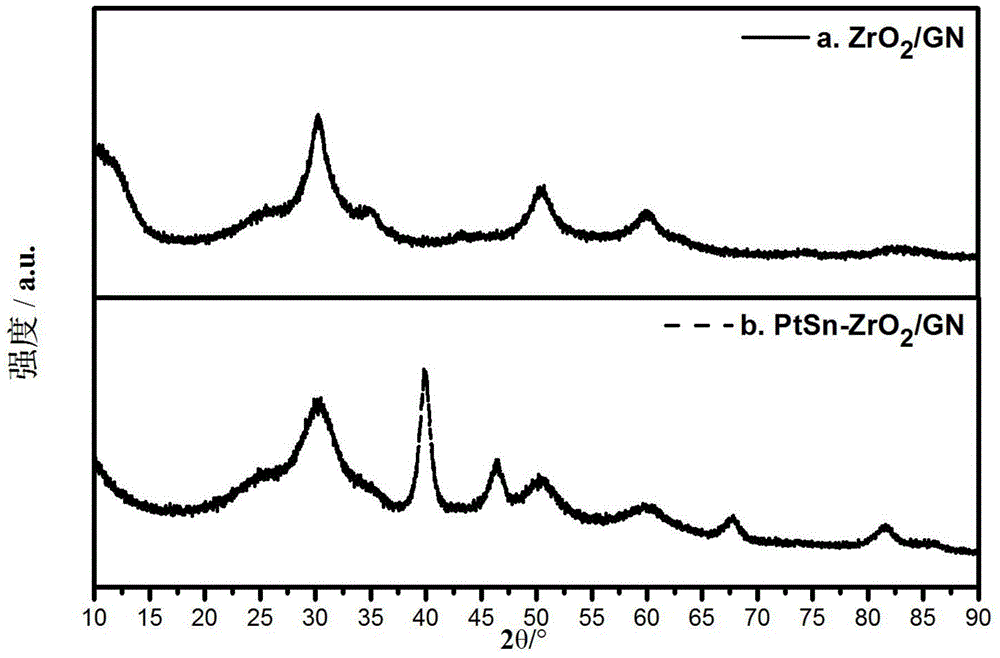

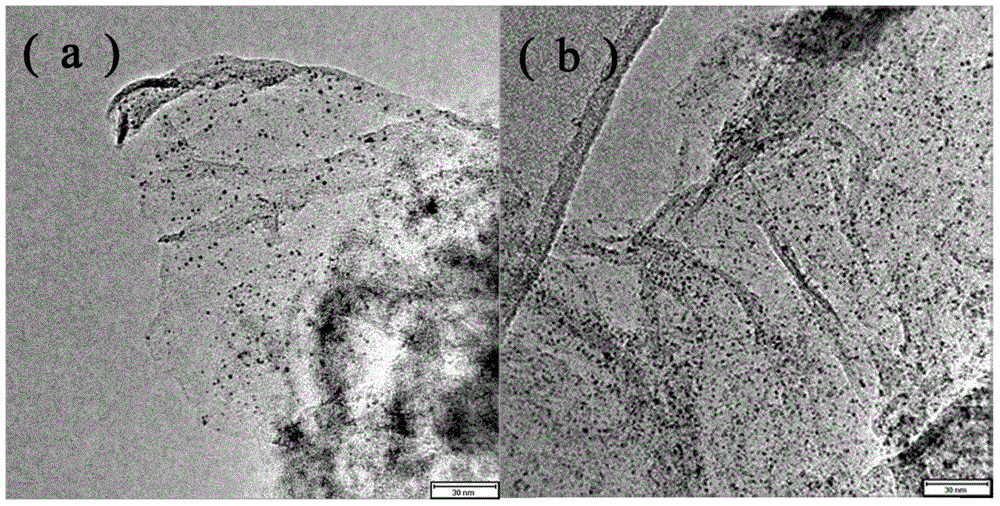

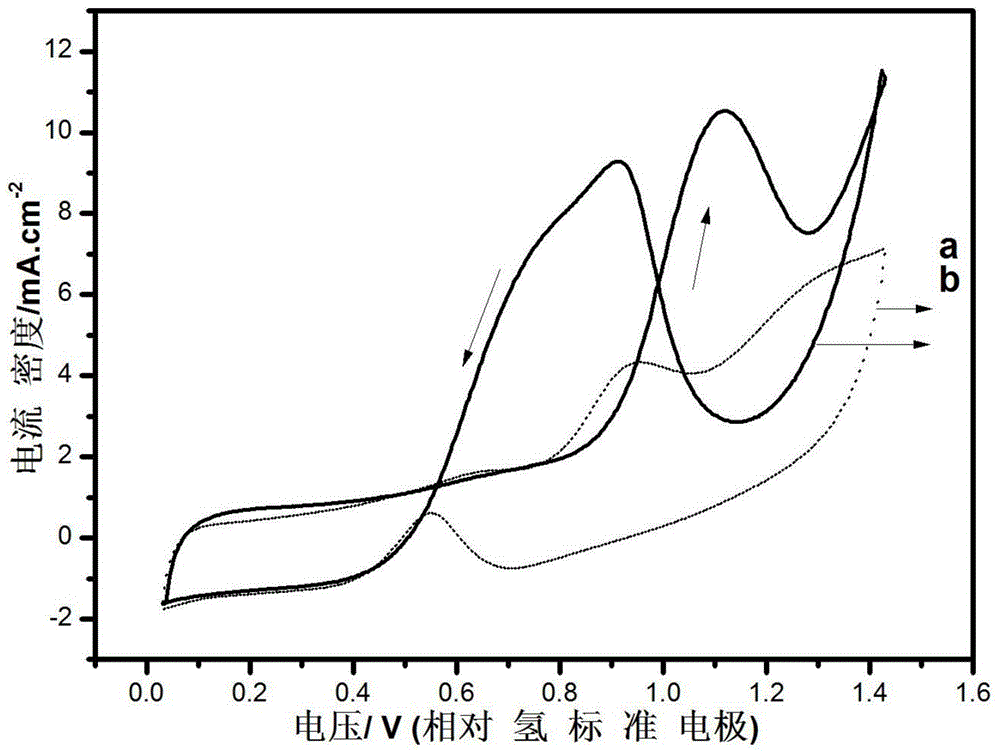

[0021] A. Disperse 22.57g of zirconium nitrate and 200mg of graphite oxide (GO) in deionized water to prepare 100ml of suspension A, add dropwise 15ml of 10g / L sodium borohydride aqueous solution, stir for 1h, filter with suction, and use 80% ethanol solution Washed and dried to obtain pre-reduced ZrO 2 / GN powder;

[0022] B. Ultrasonic disperse 1 g of the sample obtained in step A in 100ml ethylene glycol solution to prepare suspension B, and ultrasonically disperse for 10 minutes. React suspension B at 130°C for 5 hours, filter with suction, and use 80% Washed with ethanol solution and dried to obtain ZrO 2 / GN Powder. Calcination at 550°C for 1 hour under a nitrogen atmosphere;

[0023] C. Take 1.1ml of chloroplatinic acid solution with a concentration of 3g / 100ml and 14.4mg of stannous chloride, and mix them according to the Pt:Sn molar ratio of 1:1 to prepare solution C, and mix solution C with 66ml of ethylene glycol. Use 1mol L -1 Sodium hydroxide solution in ethy...

Embodiment 2

[0027] A. Disperse 8.03mg of zirconium nitrate and 200mg of graphite oxide (GO) in deionized water to prepare 100ml of suspension A, add dropwise 25ml of 10g / L sodium borohydride aqueous solution, stir for 1.5h, filter with suction, and use 80% ethanol The solution was washed and dried to obtain pre-reduced ZrO 2 / GN powder;

[0028] B. Ultrasonic disperse 1.5g of the sample obtained in step A in 100ml ethylene glycol solution to prepare suspension B, ultrasonically disperse for 15min, react suspension B at 140°C for 4 hours, suction filter, and use 80% Washed with ethanol solution, dried to get ZrO 2 / GN Powder. Calcination at 600°C for 1 hour under nitrogen atmosphere;

[0029] C. Take 1.26ml of chloroplatinic acid solution with a concentration of 3g / 100ml and 11.0mg of stannous chloride to prepare solution C according to the Pt:Sn molar ratio of 1.5:1, and mix solution C with 75.6ml of ethylene glycol. Use 2mol L -1 Adjust pH=11 with sodium hydroxide and ethylene glyco...

Embodiment 3

[0036] A. Disperse 6.28g of zirconium nitrate and 200mg of graphite oxide (GO) in deionized water to prepare suspension A, add dropwise 30ml of 10g / L sodium borohydride aqueous solution, stir for 2h, filter with suction, and wash with 80% ethanol solution , dried to obtain pre-reduced ZrO 2 / GN powder;

[0037] B. Ultrasonic disperse 2g of the sample prepared in step A in 100ml ethylene glycol solution to prepare suspension B, and ultrasonically disperse for 20min, react suspension B at 160°C for 3 hours, filter with suction, and use 80% Washed with ethanol solution and dried to obtain ZrO 2 / GN Powder. Calcination at 650°C for 1 hour under nitrogen atmosphere;

[0038] C. Take 1.36ml of chloroplatinic acid solution with a concentration of 3g / 100ml and 8.9mg of stannous chloride to prepare solution C according to the Pt:Sn molar ratio of 2:1, and mix solution C with 81.6ml of ethylene glycol. Use 3mol L -1 Adjust pH=12 with sodium hydroxide and ethylene glycol solution; r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com