Compound active carbon decolorizing agent

An activated carbon decolorization and composite technology, applied in the field of decolorizers, can solve the problems of insufficient filtration speed, poor deodorization ability, and insufficient mother liquor transmittance, and achieves increased application area and space, and strong anti-reversion ability. , the effect of reducing the original dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of composite activated carbon decolorizing agent, it is made up of following material component and weight percentage:

[0026] Coconut shell activated carbon 50%, wood activated carbon 30%, resin 10%, activated clay 5%, diatomaceous earth 5%.

[0027] Fully mix the above-mentioned powdered material raw materials with good proportions, carry out preliminary screening (for example, according to the standard of 6-50 mesh), and then dry with hot air until the moisture content is 10%-25%, kneading, and then carry out in the rotary kiln Activation, followed by recovery and rinsing, and finally dehydration and drying, ball milling, sorting, inspection and packaging to obtain the final product. The finished product is used to decolorize brown sugar into white sugar. Compared with independent activated carbon, it has stronger adsorption, high decolorization efficiency, and better color of white sugar. Moreover, compared with conventional activated carbon of equal quality...

Embodiment 2

[0035] A kind of composite activated carbon decolorizing agent, it is made up of following material component and weight percentage:

[0036] Coconut shell activated carbon 55%, wood activated carbon 25%, resin 10%, activated clay 5%, diatomaceous earth 5%.

[0037] Fully mix the above-mentioned powdered material raw materials with good proportions, carry out preliminary screening (for example, according to the standard of 10-60 mesh), and then dry with hot air until the moisture content is 10%-25%, kneading, and then carry out kneading in a rotary kiln Activation, followed by recovery and rinsing, and finally dehydration and drying, ball milling, sorting, inspection and packaging to obtain the final product. The finished product is applied to the decolorization of monosodium glutamate. Compared with independent activated carbon, it has stronger adsorption, high decolorization efficiency, good color of the prepared white sugar, fast filtration speed and high light transmittanc...

Embodiment 3

[0039] A kind of composite activated carbon decolorizing agent, it is made up of following material component and weight percentage:

[0040] Coconut shell activated carbon 50%, wood activated carbon 25%, resin 15%, activated clay 5%, diatomaceous earth 5%.

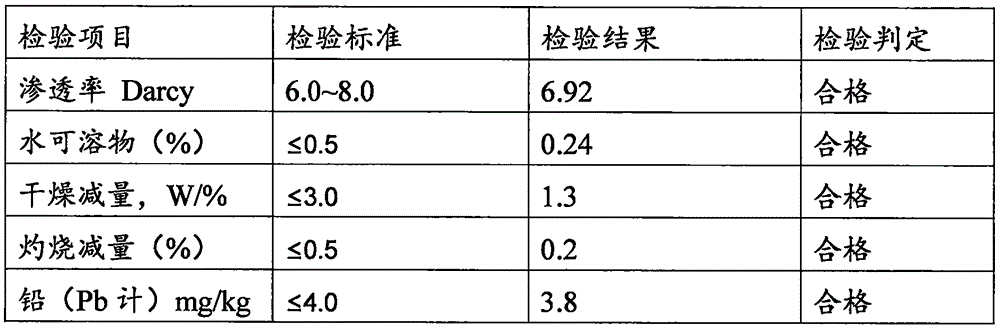

[0041] Fully mix the above-mentioned powdered material raw materials with good proportions, carry out preliminary screening (for example, according to the standard of 20-70 mesh), and then dry with hot air until the moisture content is 10%-25%, kneading, and then carry out kneading in a rotary kiln Activation, followed by recovery and rinsing, and finally dehydration and drying, ball milling, sorting, inspection and packaging to obtain the final product. The finished product is applied to beer filtration, and compared with independent activated carbon, it has stronger adsorption, high decolorization efficiency, and the fineness of the prepared liquor is good.

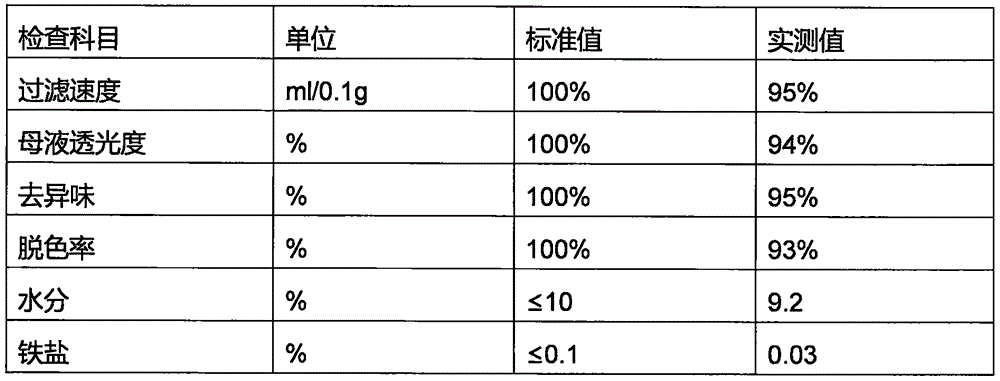

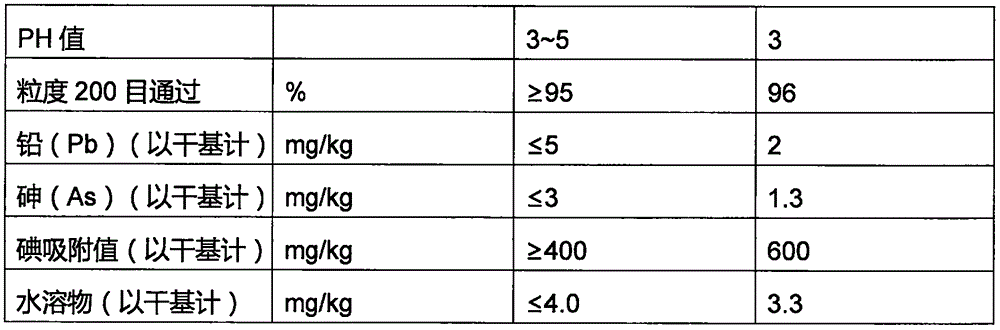

[0042] The detection report that the composite decolorizer t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com