Nanometal particles and preparation method thereof

A technology of nano-metal particles and metal precursors, applied in metal processing equipment, nanotechnology, nanotechnology, etc., can solve the problems of uneven and insufficient reaction, metal particle size and particle size distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

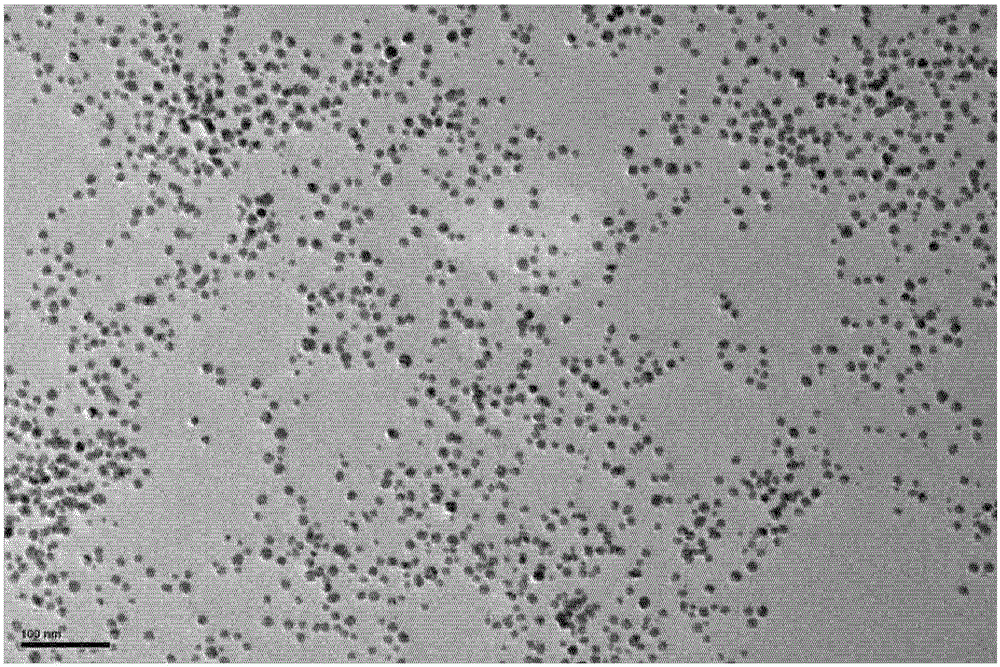

Embodiment 1

[0104] Step A: Preparation of Silver Nitrate Solution

[0105] A saturated silver nitrate solution was prepared by dissolving 585 g of silver nitrate (purchased from Sigma Aldrich) in 100 g of deionized water at 80°C. Add extra silver nitrate to it to keep it saturated. Then, the saturated solution was flushed with nitrogen gas for 10 minutes, and additional water was added thereto to compensate for the water lost during flushing. Next, the solution was allowed to stand to ensure that undissolved silver nitrate crystals settled at the bottom of the solvent, and the solution was maintained at 80°C.

[0106] Step B: Prepare the stock solution

[0107] 23g of PVP (K30, available from Sigma Aldrich) was dissolved in 1kg of deionized water, 34g of tannic acid (available from Sigma Aldrich) was dissolved in 1kg of deionized water, 25.5g of ammonia water (28wt% concentration, purchased from from Sigma Aldrich) was dissolved in 1 kg of deionized water, and the above three solutions...

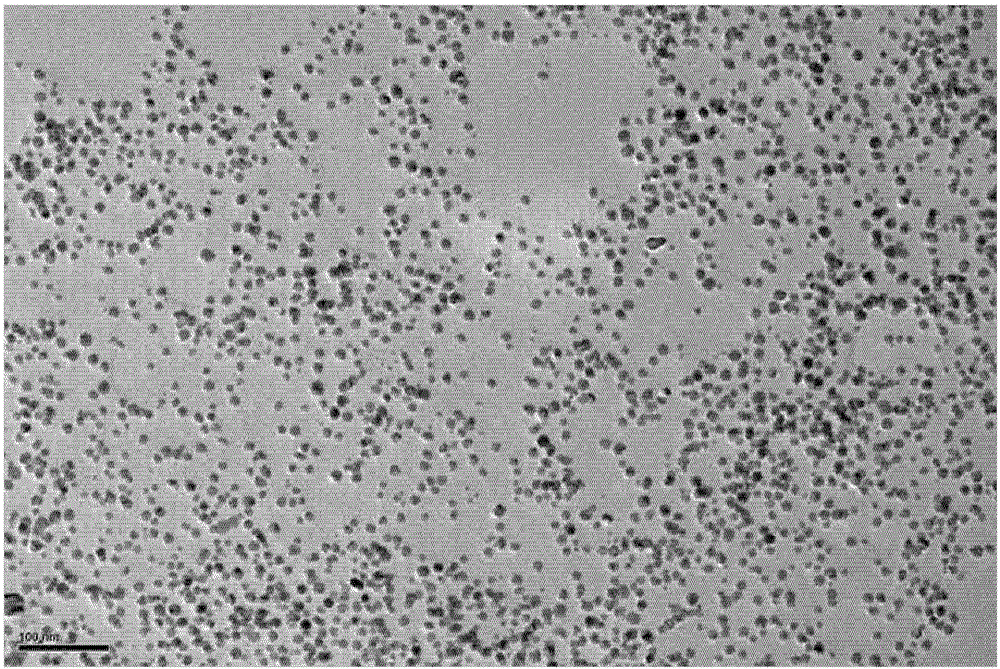

Embodiment 2

[0113] Step A: Preparation of silver nitrate solution A saturated silver nitrate solution was prepared by dissolving 222 g of silver nitrate (purchased from Sigma Aldrich) in 100 g of deionized water at 20°C. Add extra silver nitrate to it to keep it saturated. Then, the saturated solution was flushed with nitrogen gas for 10 minutes, and additional water was added thereto to compensate for the water lost during flushing. The solution was then allowed to stand to ensure that undissolved silver nitrate crystals settled at the bottom of the solvent, and the solution was maintained at 20°C.

[0114] Step B: Prepare the stock solution

[0115] 23g of PVP (K30, available from Sigma Aldrich) was dissolved in 1kg of deionized water, 34g of tannic acid (available from Sigma Aldrich) was dissolved in 1kg of deionized water, 25.5g of ammonia water (28wt% concentration, purchased from (from Sigma Aldrich) was dissolved in 1 kg of deionized water, the above solution was mixed into a 20 ...

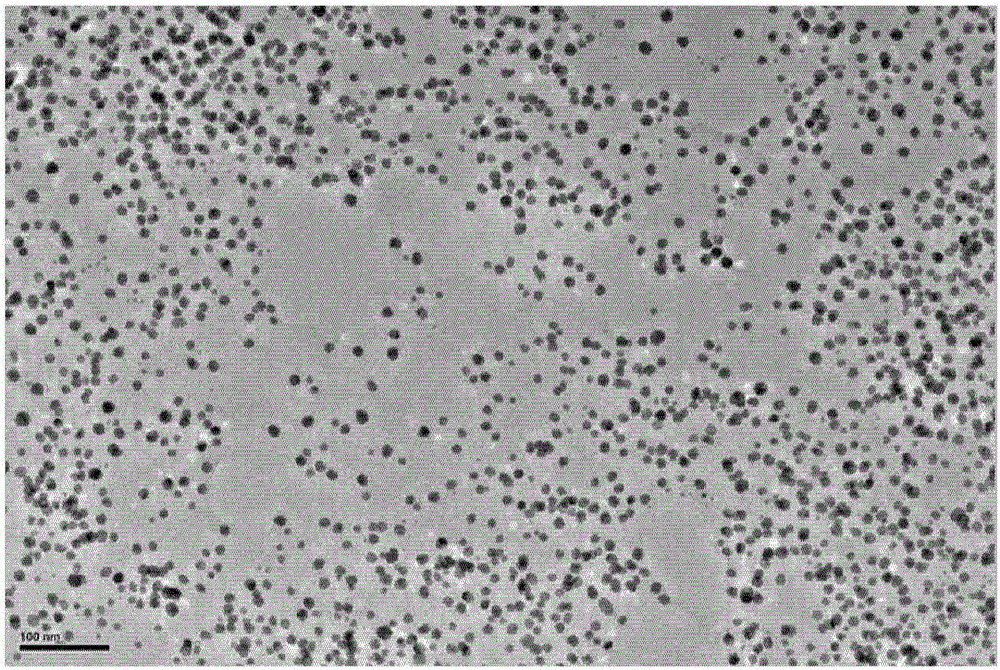

Embodiment 3

[0121] Step A: Preparation of Silver Nitrate Solution

[0122] A saturated silver nitrate solution was prepared by dissolving 585 g of silver nitrate (purchased from Sigma Aldrich) in 100 g of deionized water at 80°C. Add extra silver nitrate to it to keep it saturated. Then, the saturated solution was flushed with nitrogen gas for 10 minutes, and additional water was added thereto to compensate for the water lost during flushing. Next, the solution was allowed to stand to ensure that undissolved silver nitrate crystals settled at the bottom of the solvent, and the solution was maintained at 80°C.

[0123] Step B: Prepare the stock solution

[0124] 23g of PVP (K30, available from Sigma Aldrich) was dissolved in 1kg of deionized water, 34g of tannic acid (available from Sigma Aldrich) was dissolved in 1kg of deionized water, 25.5g of ammonia water (28wt% concentration, purchased from Dissolved from Sigma Aldrich) in 1 kg of deionized water, the above three solutions were mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com