Preparing method of PVC composite board

A composite board and auxiliary extrusion technology, which is applied in the field of PVC composite board preparation, can solve the problems that the decorative layer is easy to foam, crack, and affect the appreciation of the PVC composite board, and achieve the effect of good compatibility and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings of the description.

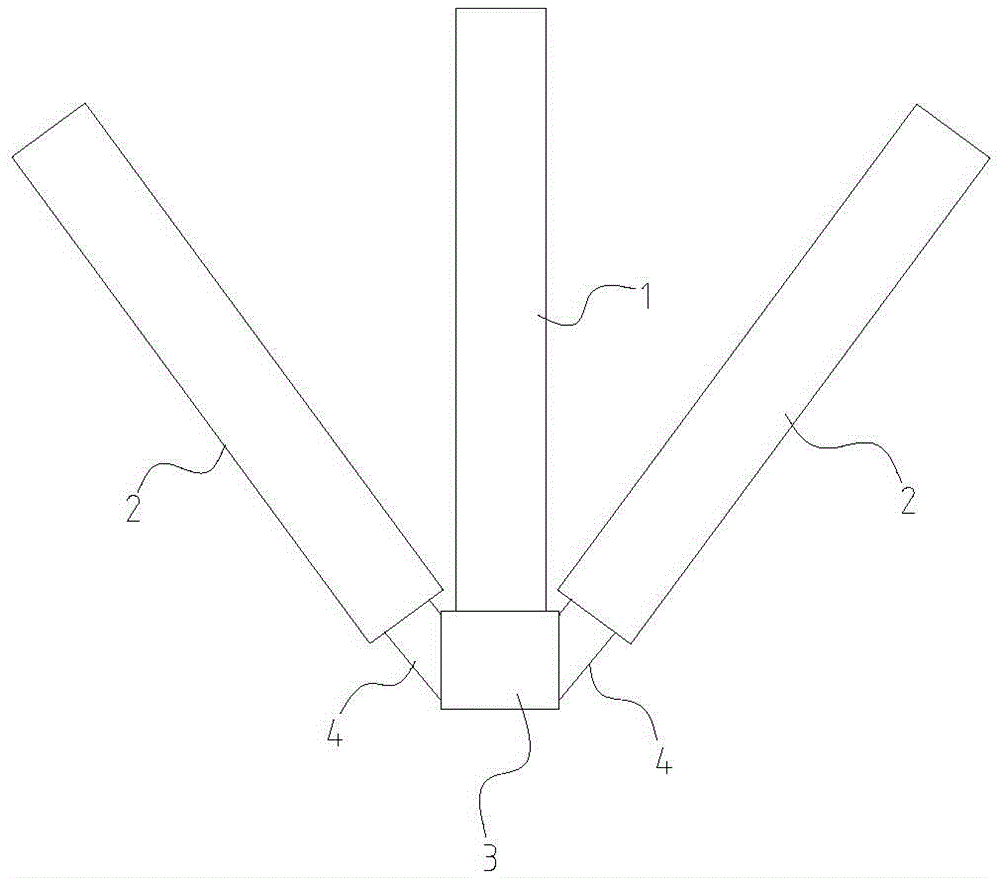

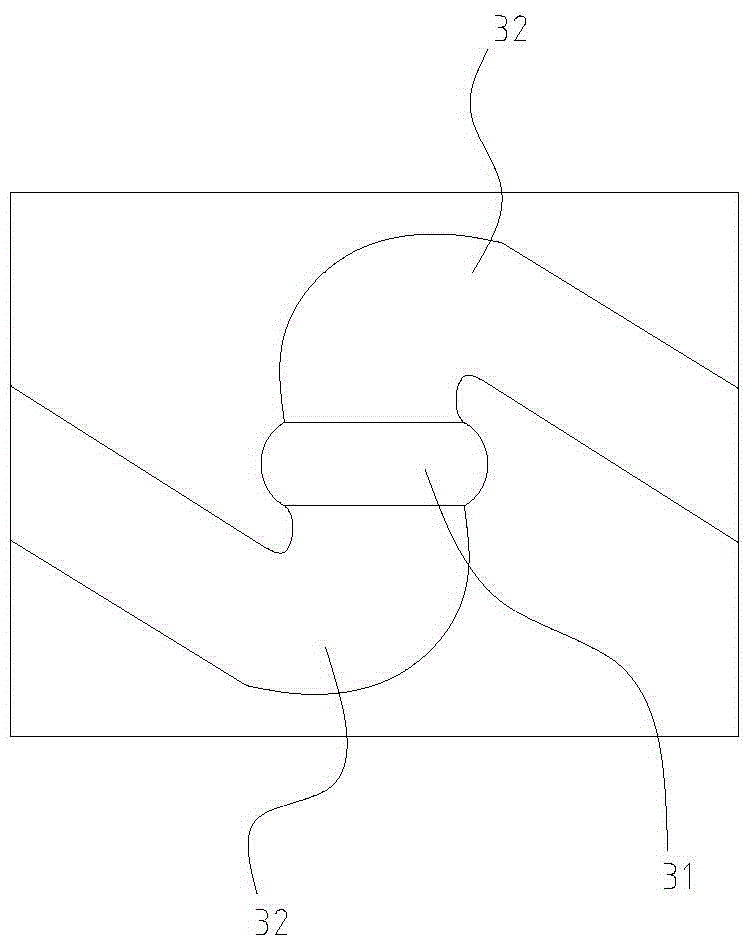

[0024] Such as figure 1 Shown, a kind of preparation method of PVC composite board, described composite board is compounded by co-extrusion process by middle layer and upper and lower two surface layers, middle layer is PVC wood-plastic layer, surface layer is PVC layer, middle layer is through main extruding Extruder 1 is formed, and the two layers of skin are respectively formed by two auxiliary extruders 2.

[0025] According to the weight ratio, the main raw materials used in the middle layer include 90~120 parts of PVC resin, 75~100 parts of calcium carbonate, 10~12 parts of wood powder, 6~8 parts of stabilizer, 1.5~2 parts of lubricant, and 3 parts of plasticizer. ~4 parts and 5~8 parts of blowing agent. In proportion by weight, the auxiliary raw materials used in the surface layer include 90~120 parts of PVC resin powder, 75~100 parts of cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com