Anti-bending and anti-thermal shock far-infrared fine pottery billet and anti-bending and anti-thermal shock far-infrared fine pottery product and method prepared therefrom

一种远红外、抗热震的技术,应用在黏土制品、应用、家里用具等方向,能够解决难以满足生产的发展和市场应用的需求、耐热震性能低、抗冲击能力差等问题,达到提高远红外发射功能、成型性能好、提高可塑性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

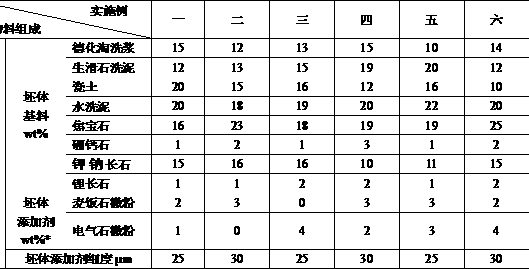

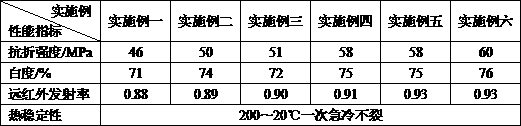

[0019] The present invention will be further described in detail below in conjunction with the examples.

[0020] Those skilled in the art will understand that the following examples are only for illustrating the present invention and should not be considered as limiting the scope of the present invention. The chemical composition (mass percentage) of Dehua elutriated pulp in the present invention is: SiO 2 66.64%, Al 2 o 3 22.54%, Fe 2 o 3 0.74%, MgO 0.35%, K 2 O 2.45%, burning reduction 7.28%. The chemical composition (mass percentage) of raw talc washing mud is: SiO 2 59.95%, Al 2 o 3 1.33%, Fe 2 o 3 0.16%, MgO 28.82%, CaO 2.08%, ignition loss 7.66%. The chemical composition (mass percentage) of potassium albite feldspar is: SiO 2 67.46%, Al 2 o 3 17.63%, Fe 2 o 3 0.14%, CaO 0.41%, K 2 0 10.15%, Na 2 O 2.89%, BaO 0.8%, ignition loss 0.52%. The chemical composition (mass percentage) of lithium feldspar is: SiO 2 67.50%, Al 2 o 3 19.68%, Fe 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com