Black fungus selenium-rich culture medium and method for producing black fungi thereof

A technology of black fungus and culture medium, applied in the field of black fungus liquid fermentation medium and its use of liquid strain technology to produce black fungus, can solve the problems of low nutritional content of products, long culture period, low efficiency, etc., and achieve the goal of improving selenium The effect of content, easy source and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

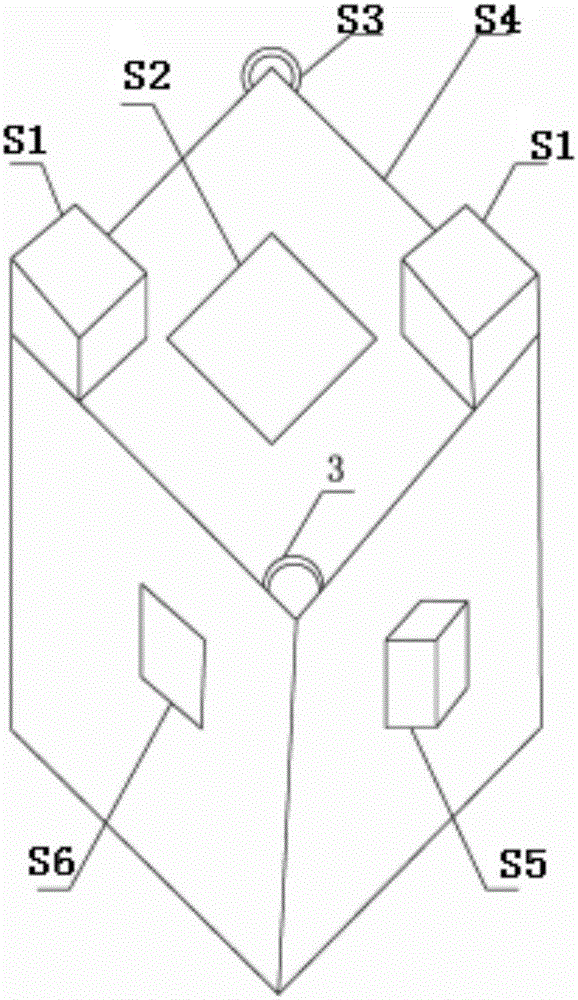

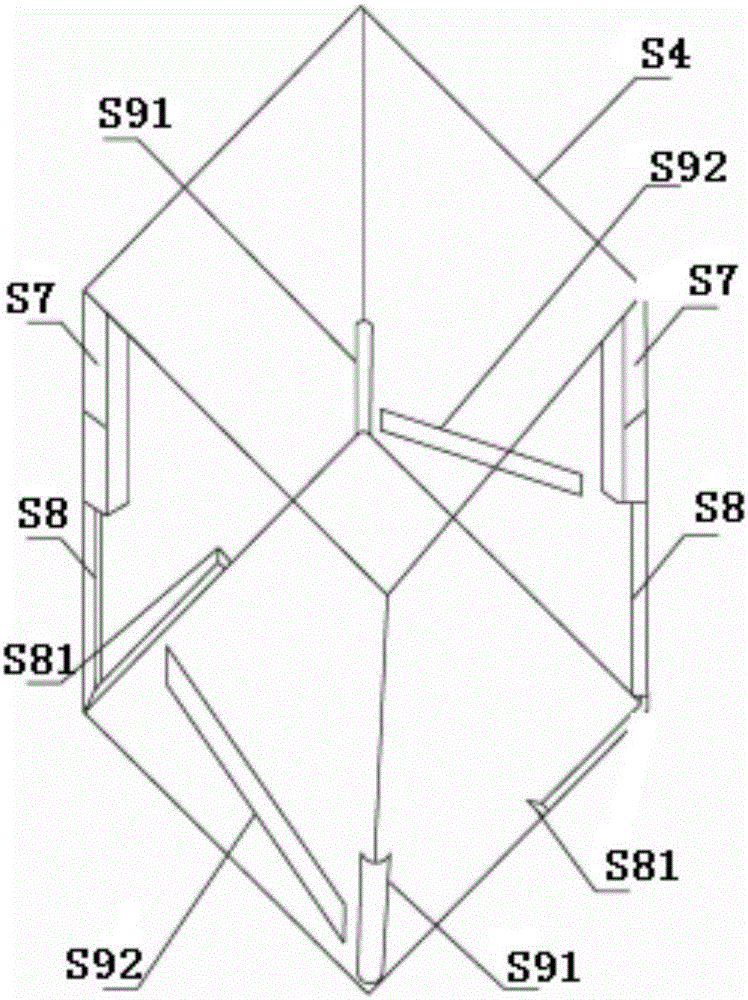

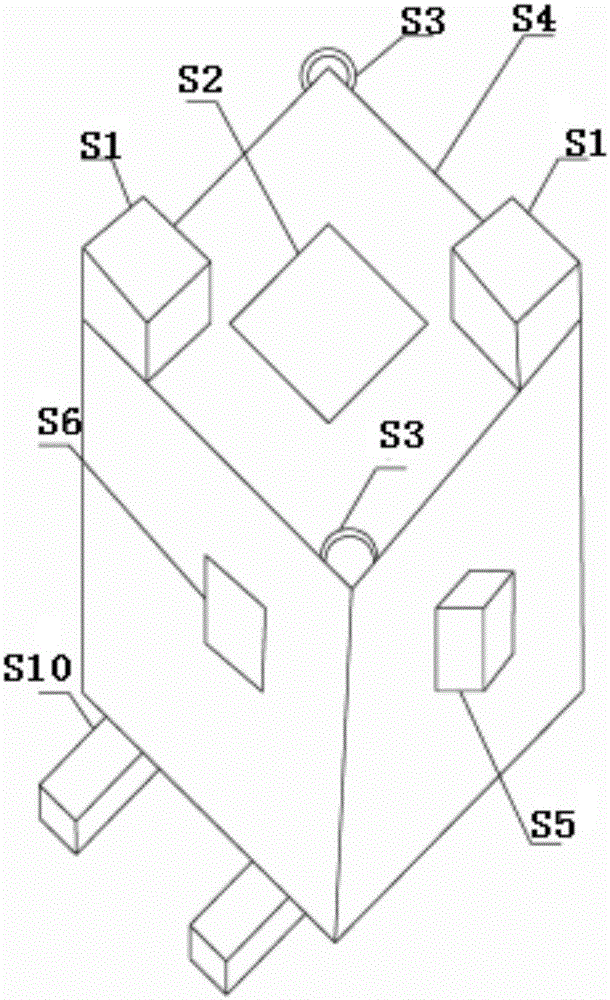

Image

Examples

Embodiment 1

[0052] Preparation of liquid selenium-enriched strains: add 2.5% potato flour, 3.0% bran flour, 3.5% corn flour, 0.7% sugar, 0.3% glucose, 5mg / kg sodium selenite, and 100g potassium dihydrogen phosphate to the fermenter , magnesium sulfate 50g, water 100L, canning, sterilizing, cooling, injecting 1000mL of black fungus bottle liquid stock under aseptic conditions, the inoculum volume is 2% by volume; the fermentation temperature is 23±2°C, ventilated The volume is 105±5m 3 / h, the initial pH value is 7.0, fermented for 6 days, and the obtained black fungus industrial production liquid selenium-enriched strain;

[0053] Solid selenium-enriched medium: material preparation: by weight percentage, weigh 8,700g of sawdust, 1,000g of selenium-enriched Juncao, 200g of wheat bran, and 100g of gypsum, and set aside; add 350g of fresh soybean oil, bag, sterilize, and cool to obtain solid-enriched Selenium medium;

[0054] Inoculation and cultivation: the liquid selenium-enriched strai...

Embodiment 2

[0056] Preparation of liquid selenium-enriched strains: add 2.5% potato flour, 3.0% bran flour, 3.5% corn flour, 0.7% sugar, 0.3% glucose, 5mg / kg sodium selenite, and 100g potassium dihydrogen phosphate to the fermenter , magnesium sulfate 50g, water 100L, canning, sterilizing, cooling, injecting 1000mL of black fungus bottle liquid stock under aseptic conditions, the inoculum volume is 2% by volume; the fermentation temperature is 23±2°C, ventilated The volume is 105±5m 3 / h, the initial pH value is 7.0, fermented for 6 days, and the obtained black fungus industrial production liquid selenium-enriched strain;

[0057] Solid selenium-enriched medium: material preparation: by weight percentage, weigh 8200g of sawdust, 1500g of selenium-enriched Juncao, 200g of wheat bran, and 100g of gypsum, and set aside; add 350g of fresh soybean oil, bag, sterilize, and cool to obtain solid rich Selenium medium;

[0058] Inoculation and cultivation: the liquid selenium-enriched strains are...

Embodiment 3

[0060] Preparation of liquid selenium-enriched strains: add 2.5% potato flour, 3.0% bran flour, 3.5% corn flour, 0.7% sugar, 0.3% glucose, 5mg / kg sodium selenite, and 100g potassium dihydrogen phosphate to the fermenter , magnesium sulfate 50g, water 100L, canning, sterilizing, cooling, injecting 1000mL of black fungus bottle liquid stock under aseptic conditions, the inoculum volume is 2% by volume; the fermentation temperature is 23±2°C, ventilated The volume is 105±5m 3 / h, the initial pH value is 7.0, fermented for 6 days, and the obtained black fungus industrial production liquid selenium-enriched strain;

[0061] Solid selenium-enriched medium: material preparation: by weight percentage, weigh 6100g of sawdust, 2300g of selenium-enriched Juncao, 1500g of wheat bran, 100g of gypsum, and set aside; add 350g of fresh soybean oil, bag, sterilize, and cool to obtain solid rich Selenium medium;

[0062] Inoculation and cultivation: the liquid selenium-enriched strains are in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com