Connecting plate as well as preparation method and application thereof

A technology for connecting plates and equipment, applied in the fields of grease-resistant connecting plates, high temperature resistance and ozone resistance, can solve the problems of poor heat-resistant air aging, increased use costs of connecting plates, poor hardness, etc., and achieves good resistance to lubricant media. , The effect of improving ozone resistance and improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

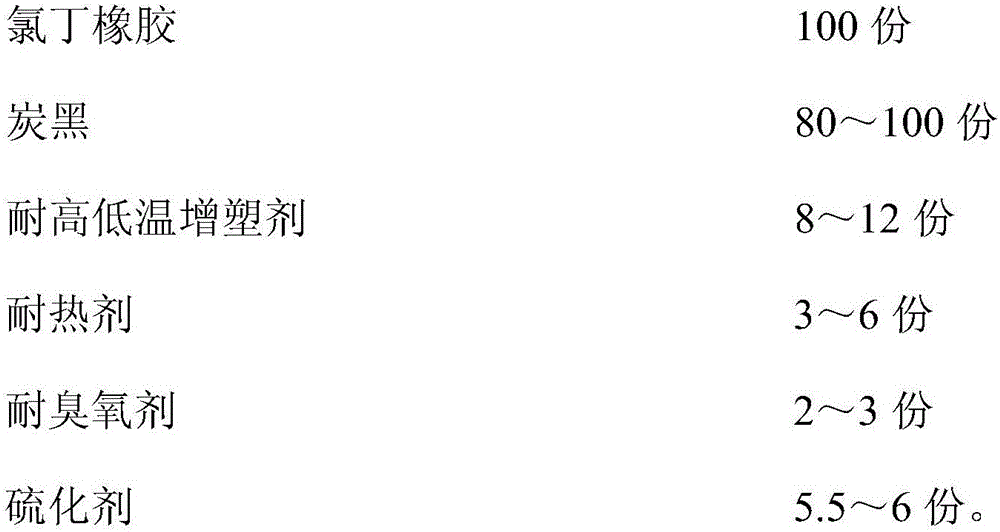

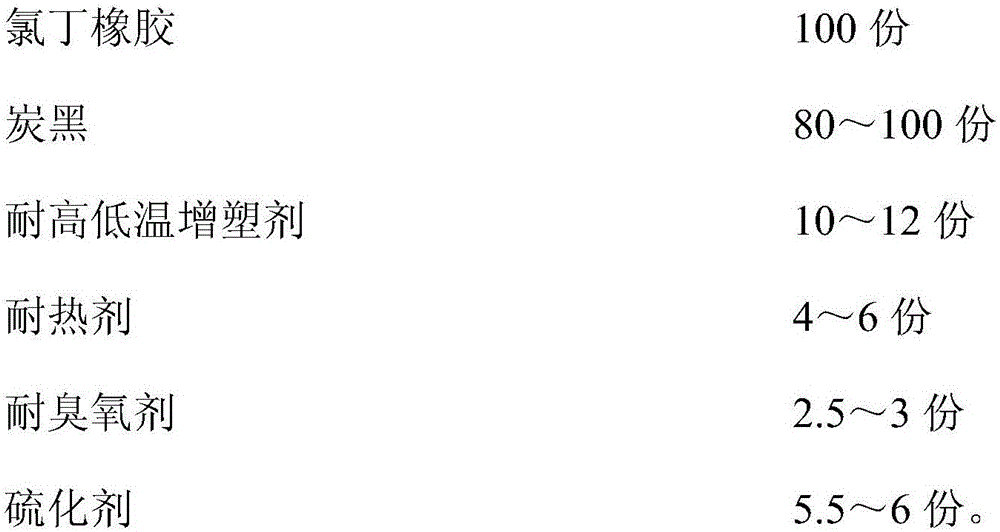

Method used

Image

Examples

Embodiment 1

[0058] (1) First, 100 parts of chloroprene rubber, 90 parts of carbon black, 10 parts of high and low temperature resistant plasticizer (mixture of fatty oil plasticizer and synthetic plasticizer), 5 parts of heat resistant agent ( Substituted diphenylamine: phenylnaphthylamine: p-phenylenediamine derivative = 2:1:2), 3 parts of anti-ozone agent are placed in the internal mixer at a temperature of 95°C and a pressure of 110Kgf / cm 2 Carry out banburying under the condition of banburying for 6 minutes, obtain banburying rubber;

[0059] (1)' Then, the above-mentioned banbury rubber is detected, and screening out hardness therefrom is 76 degrees, and intensity is 15.6MPa, and elongation is 216% banbury rubber.

[0060] (2) Put the screened banbury rubber into an open mill and carry out open milling for 4 minutes at a temperature of 55° C. and extrude to obtain molded rubber;

[0061] (3) Then put the molded rubber into the mold in the vulcanization equipment, pressurize 170Kgf / c...

Embodiment 2

[0065] (1) First, 100 parts of chloroprene rubber, 80 parts of carbon black, 10 parts of high and low temperature resistant plasticizers (mixture of fatty oil plasticizers and synthetic plasticizers), 4 parts of heat resistant agents ( Substituted diphenylamine: phenylnaphthylamine: p-phenylenediamine derivative = 1:1:2), 3 parts of anti-ozone agent are placed in the internal mixer at a temperature of 95°C and a pressure of 110Kgf / cm 2 Under the above conditions, banburying was carried out for 6 minutes to obtain banburying rubber.

[0066] (1)' Then, the above-mentioned banburying rubber is detected, and screening out hardness is 72 degree therefrom, and intensity is 16.4MPa, the banburying rubber of elongation 237%;

[0067] (2) Put the screened banbury rubber into an open mill and carry out open milling for 4 minutes at a temperature of 55° C. and extrude to obtain molded rubber;

[0068] (3) Then put the molded rubber into the mold in the vulcanization equipment, pressuri...

Embodiment 3

[0072] (1) First, 100 parts of chloroprene rubber, 100 parts of carbon black, 10 parts of high and low temperature resistant plasticizer (mixture of fatty oil plasticizer and synthetic plasticizer), 6 parts of heat resistant agent ( Substituted diphenylamine: phenylnaphthylamine: p-phenylenediamine derivatives = 2:2:2), 3 parts of ozone resistant agent are placed in the internal mixer at a temperature of 95°C and a pressure of 110Kgf / cm 2 Under the above conditions, banburying was carried out for 6 minutes to obtain banburying rubber.

[0073] (1)' Then, the above-mentioned banbury rubber is detected, and screening out hardness is 78 degree therefrom, and intensity is 16.1MPa, and elongation is 204% banbury rubber;

[0074] (2) Put the screened banbury rubber into an open mill and carry out open milling for 4 minutes at a temperature of 55° C. and extrude to obtain molded rubber;

[0075] (3) Then put the molded rubber into the mold in the vulcanization equipment, pressurize ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com