A kind of water-based multifunctional printing ink

A printing ink and multi-functional technology, applied in the field of water-based multi-functional printing ink, can solve the problems of many varieties, occupying storage space, increasing difficulty in production and management, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

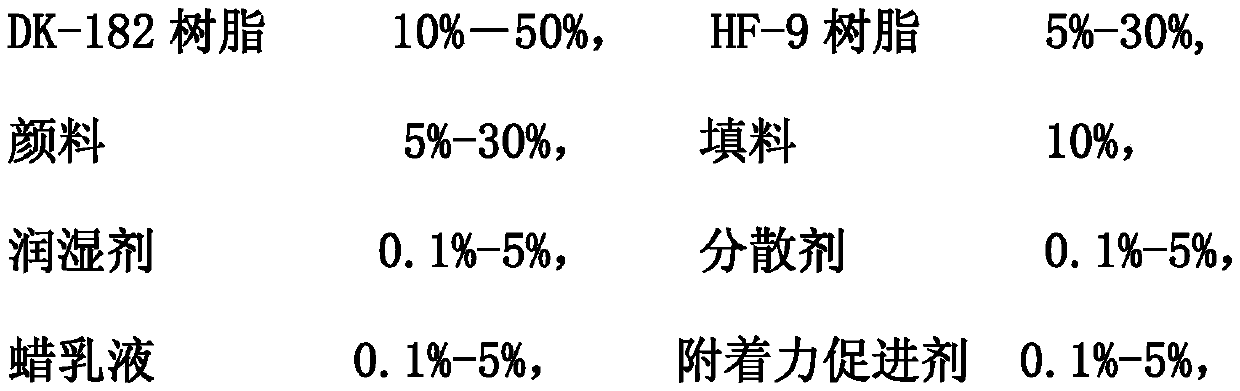

[0028] A kind of water-based multifunctional printing ink, the weight percent of its formula composition is:

[0029]

[0030]

[0031] Its preparation method comprises the following steps:

[0032] Put HF-9 resin, wetting agent, dispersant, and alcohol into the pot, start stirring; put the pigment into it and disperse it evenly for 20-30 minutes, and then use a sand mill to grind and disperse until the fineness is ≤10 microns. Put in the remaining materials, stir for 20-30 minutes, adjust the viscosity and hue, pass the inspection, filter with 120-mesh gauze, and pack into finished products.

[0033] The pigment is primary red.

Embodiment 2

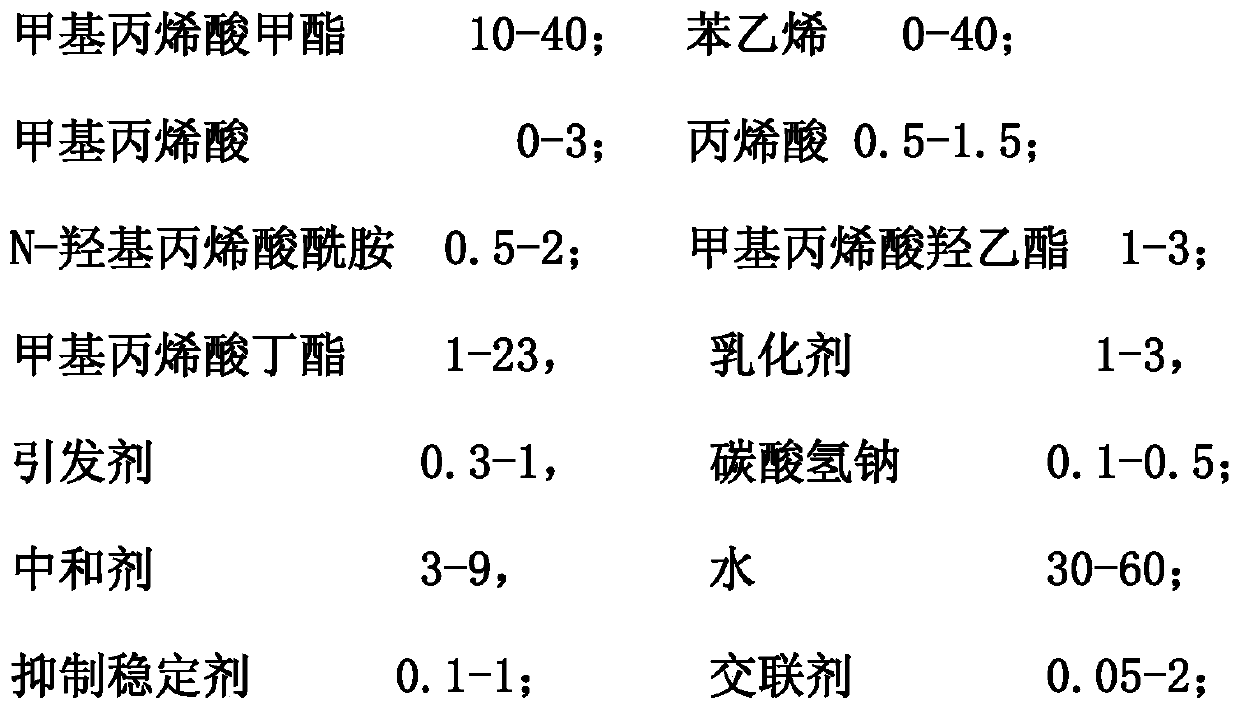

[0035] A water-based multifunctional printing ink is characterized in that: the weight percentage of its formula composition is:

[0036]

[0037] The sum of the weight percentages of each raw material is 100%.

[0038] Its preparation method comprises the following steps:

[0039] Put HF-9 resin, wetting agent, dispersant and alcohol into the pot, start stirring; then put in pigments and fillers to disperse evenly, and the dispersion time is 20-30 minutes; then grind and disperse with a sand mill until the fineness≤ 10 microns, put the rest of the materials in, stir for 20-30 minutes, adjust the viscosity and hue, pass the inspection, filter with 120 mesh gauze, and pack into finished products.

Embodiment 3

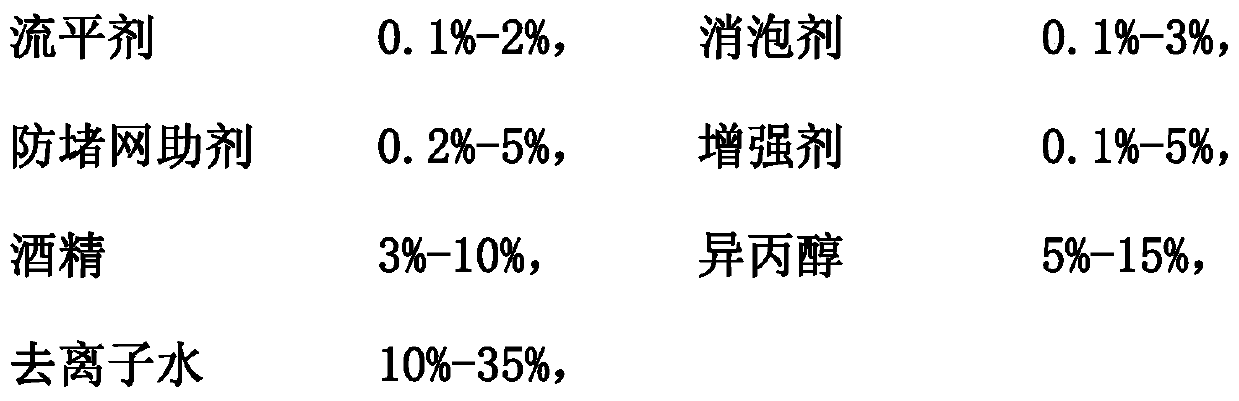

[0042] A water-based multifunctional printing ink is characterized in that: the weight percentage of its formula composition is:

[0043]

[0044] Its preparation method comprises the following steps:

[0045] Put HF-9 resin, wetting agent, dispersant and alcohol into the pot, start stirring; then put in pigments and fillers to disperse evenly, and the dispersion time is 20-30 minutes; then grind and disperse with a sand mill until the fineness≤ 10 microns, put the rest of the materials in, stir for 20-30 minutes, adjust the viscosity and hue, pass the inspection, filter with 120 mesh gauze, and pack into finished products.

[0046] The pigment is high pigment carbon black.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com