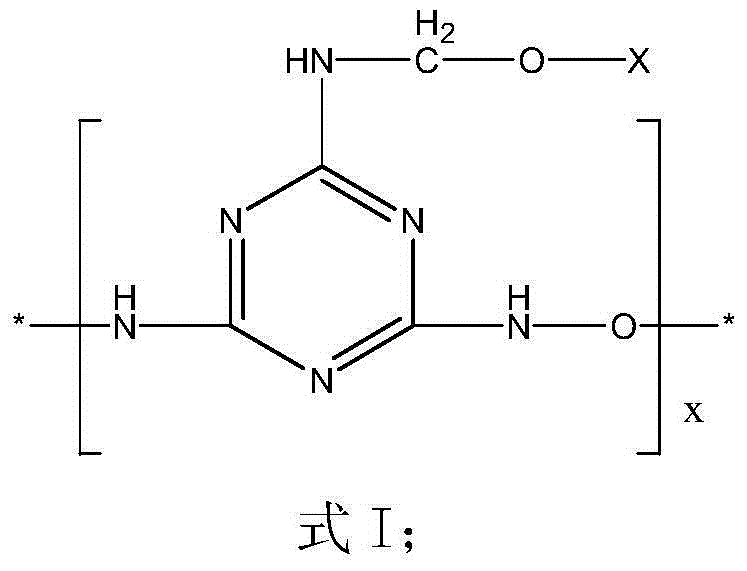

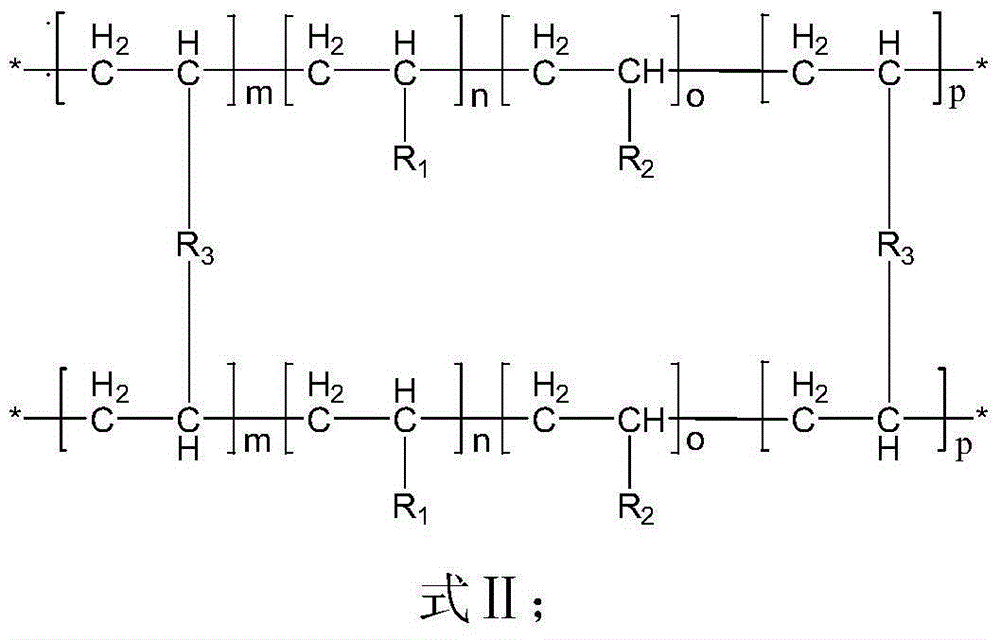

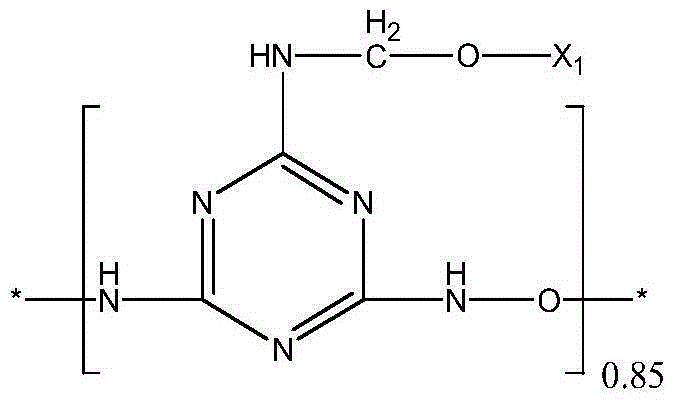

Gel plugging agent and preparation method thereof

A technology of plugging agent and gel, which is applied in the field of gel plugging agent and its preparation, can solve the problem that the gel plugging material cannot be further reacted and solidified, achieve good water absorption and expansion ability, improve burst resistance, and reduce repeated missing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Gel plugging agent, the preparation method is as follows:

[0034] (1) Weigh 50g of formaldehyde, pour it into a four-neck flask, adjust the pH value to 8.5 with triethanolamine, then add 22g of melamine, and heat it in a water bath at 65°C for 10min, the melamine dissolves and forms a transparent solution. Rapidly raise the temperature to 74°C, heat up to 85°C after the hydroxymethylation reaction for 70 minutes, adjust the pH value to 7.0 with oxalic acid solution, and react for 30 minutes to obtain the reactive material A 1 .

[0035] (2) Mix 8g of AA (acrylic acid) and 60g of reactive material A 1 Add 60g of clear water, stir well and adjust the pH to 7 with aqueous sodium hydroxide solution; then add 0.04g of cross-linking agent N, N-methylenebisacrylamide and 32g of AM (acrylamide), stir and dissolve, and then add When the temperature is raised to 40°C, add 0.2g potassium persulfate and 0.2g sodium sulfite, and let it stand to react into a gel; take out the prod...

Embodiment 2

[0040] Gel plugging agent, the preparation method is as follows:

[0041] (1) Weigh 66g of formaldehyde, pour it into a four-neck flask, adjust the pH value to 8.5 with triethanolamine, then add 22g of melamine, and heat it in a water bath at 60°C for 15min, the melamine dissolves and forms a transparent solution. Rapidly raise the temperature to 80°C, heat up to 90°C after the hydroxymethylation reaction for 90 minutes, adjust the pH value to 7.5 with oxalic acid solution, and react for 1 hour to obtain the reactive material A 2 .

[0042] (2) Mix 10g AA and 70g reactable material A 2 Add 60g of clear water, stir evenly and adjust the pH to 7 with aqueous sodium hydroxide solution; then add 30g of N,N-dimethylacrylamide and 0.04g of N,N-methylenebisacrylamide, stir and dissolve, and place in a water bath When the temperature is raised to 40°C under the conditions, add 0.2g potassium persulfate and 0.2g sodium sulfite, and let it stand still to react into a gel; take out the...

Embodiment 3

[0047] Gel plugging agent, the preparation method is as follows:

[0048] (1) Weigh 60g of formaldehyde, pour it into a four-neck flask, adjust the pH value to 8.0 with triethanolamine, then add 22g of melamine, and heat it in a water bath at 60°C for 10min, the melamine dissolves and forms a transparent solution. Rapidly raise the temperature to 70°C, hydroxymethylation reaction for 60min, then raise the temperature to 80°C, adjust the pH value to 7.5 with oxalic acid solution, and react for 2h to obtain the reactive material A 3 .

[0049] (2) Combine 18g AA and 70gA 3 Add 120g of clear water, stir well and adjust the pH to 7 with aqueous sodium hydroxide solution; then add 0.04g of N,N-methylenebisacrylamide, 14g of AM (acrylamide) and 8g of N,N-diethylacrylamide, and stir After dissolving, when the temperature is raised to 40°C in a water bath, 0.2g potassium persulfate and 0.2g sodium sulfite are added, and the reaction becomes gel after standing; the product is taken out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com