Bio-oil and combustion process taking bio-oil as fuel

A technology of bio-oil and process, which is applied in the direction of fuel, petroleum industry, liquid carbon-containing fuel, etc., and can solve problems such as complex operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in combination with specific embodiments.

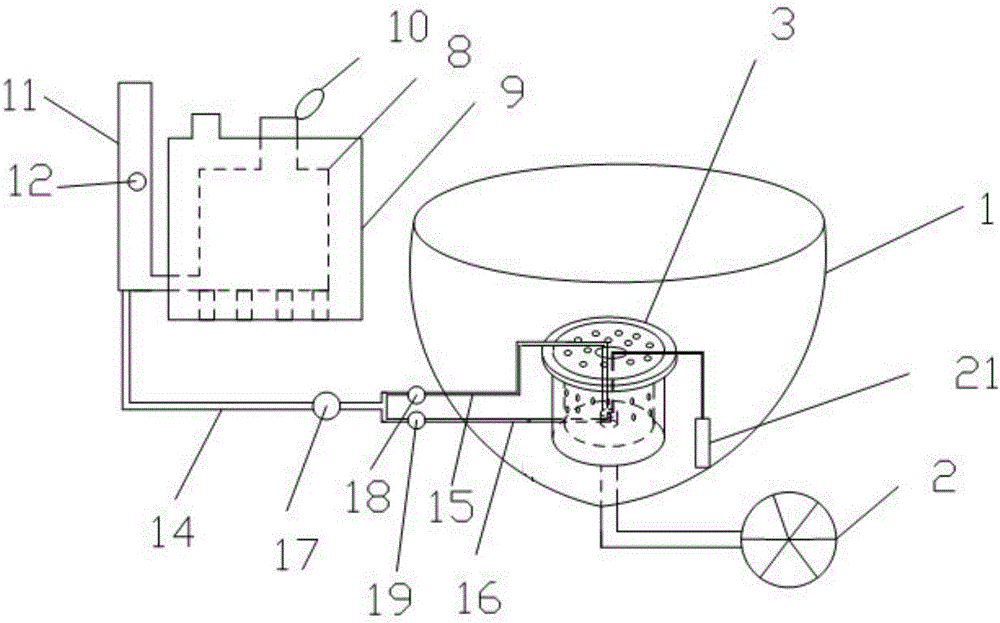

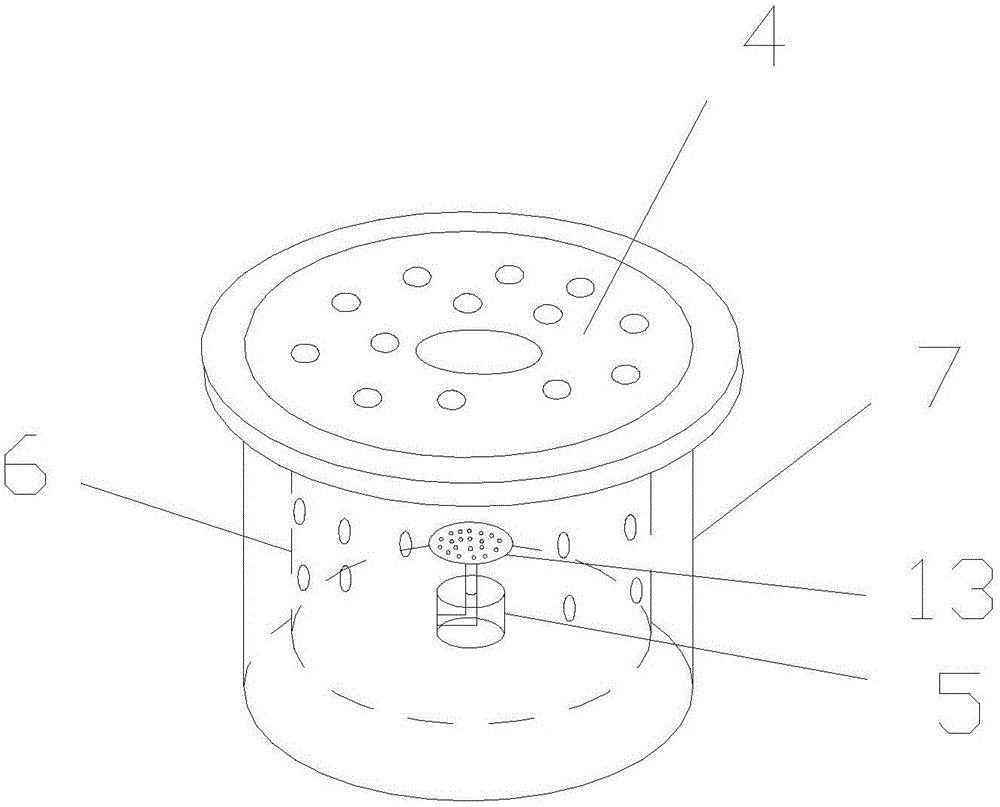

[0040] refer to figure 1 , 2 As shown, the fuel stove includes a mixed gas generator 3, and the mixed gas generator includes a fire cover 4, a stove core 5, a generator liner 6 and a generator shell 7; the generator liner is nested in the generator shell, and the generator There is a gap between the inner tank and the generator shell, and the wall of the generator inner tank is provided with a ventilation hole. The stove core 5 is fixed at the bottom center of the generator inner tank, and an "L-shaped" through-hole is arranged inside the stove core. The oil channel and the fire cover cover the opening of the inner tank of the generator, and the fire cover is evenly distributed with fire holes, and the bottom of the generator shell is provided with an air inlet, which is connected to the fan;

[0041] Add an atomizing nozzle 13 on the stove core (to realize shor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com