Water-reducible cleaning agent for integrated circuit board scaling powder

An integrated circuit and water-diluted technology, applied in the field of cleaning agent, can solve the problems of difficult drying and slow volatilization speed, and achieve the effect of stable cleaning agent, moderate volatilization degree and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

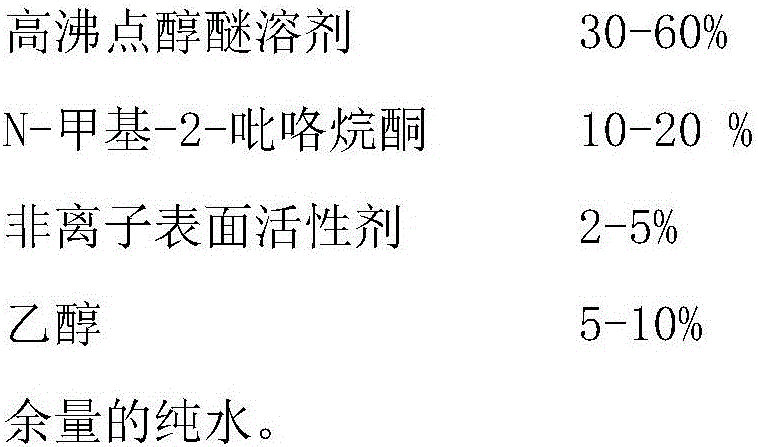

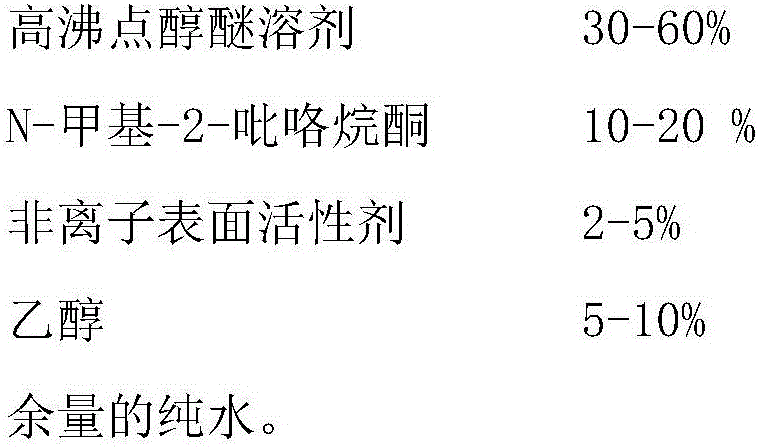

Method used

Image

Examples

Embodiment 1

[0023] In the reactor, mix diethylene glycol ethyl ether, diethylene glycol butyl ether, dipropylene glycol methyl ether, and dipropylene glycol butyl ether at the percentages of 20%, 20%, 10%, and 10% by weight, and add 10 % Ethanol, continue to stir and add 20% N-methyl-2-pyrrolidone, then add 5% high-purity water, stir for 15 minutes, add non-ionic surfactants FMEE, BEROL-226SA total 5%, continue to stir for 15 minutes to obtain a Water-diluted integrated circuit board flux cleaning agent, pay attention to keep the temperature of the reactor not exceeding 20 ℃ during the stirring process.

Embodiment 2

[0025] In the reaction kettle, mix diethylene glycol ether: diethylene glycol butyl ether: dipropylene glycol methyl ether in proportions of 30%, 10%, and 10% by weight, add 5% ethanol, continue to stir and add 20 %N-methyl-2-pyrrolidone, then add 20% high-purity water, stir for 15 minutes, add non-ionic surfactants FMEE, BEROL-226SA total 5%, continue stirring for 15 minutes to obtain a water-diluted integrated circuit board flux Cleaning agent, pay attention to keep the temperature of the reactor not exceeding 20°C during the stirring process.

Embodiment 3

[0027] In the reaction kettle, mix diethylene glycol butyl ether, dipropylene glycol methyl ether, and dipropylene glycol butyl ether at 10%, 20%, and 30% by weight, add 8% ethanol, continue to stir and add 10% N -Methyl-2-pyrrolidone, then add 14% high purity water, stir for 15 minutes, add non-ionic surfactants FMEE, BEROL-226SA total 8%, continue to stir for 15 minutes to obtain a water-diluted integrated circuit board flux cleaning agent , Pay attention to keep the temperature of the reactor not exceeding 20℃ during the stirring process.

[0028] The cleaning agent obtained in Examples 1-3 was sprayed directly on the circuit board with rosin flux and solder paste. The residual thickness of the rosin flux and solder paste was 1mm, so that the area with the flux and solder paste was completely covered by the cleaning agent. Cover, after standing at room temperature for 1 hour, directly rinse with water, the workpiece is as bright as new without flux residue.

[0029] If the resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com