Surface corrosion-preventing and color-fixing agent for metal, preparation method and application

A technology of metal surface and color fixing agent, which is applied in the direction of metal material coating process, etc., can solve the problem of easy fading of products, and achieve the effect of overcoming anti-corrosion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention will be described in detail below through specific examples, and these examples are only used to explain and illustrate the present invention and should not be construed as limiting the present invention.

[0032] A metal surface anticorrosion and color-fixing agent, which consists of 2-mercaptobenzimidazole MBI, 2-mercaptobenzoxazole MBO, benzotriazole BTA, imidazole derivatives, polyacrylic resin, polyethylene wax, lubricant And surfactant, wherein polyethylene wax accounts for 3-5% of total weight. In weight percentage, the ratio of 2-mercaptobenzimidazole MBI: 2-mercaptobenzoxazole MBO: benzotriazole BTA: imidazole derivative is 2:1:1:1. The lubricant is one or a combination of stearic acid, butyl stearate or oleamide.

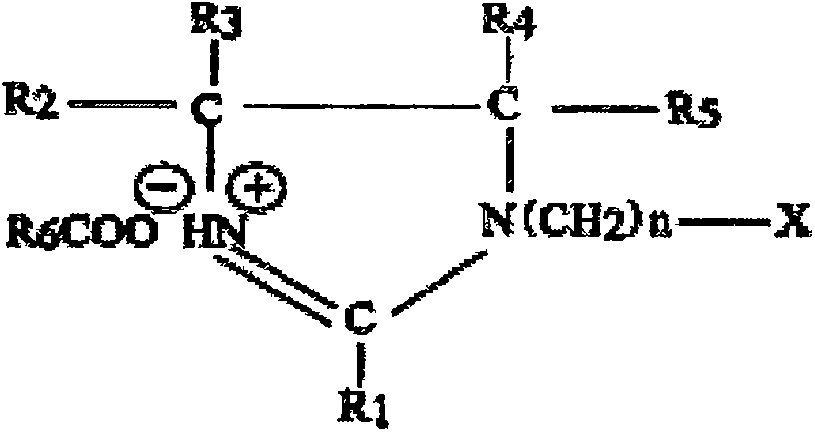

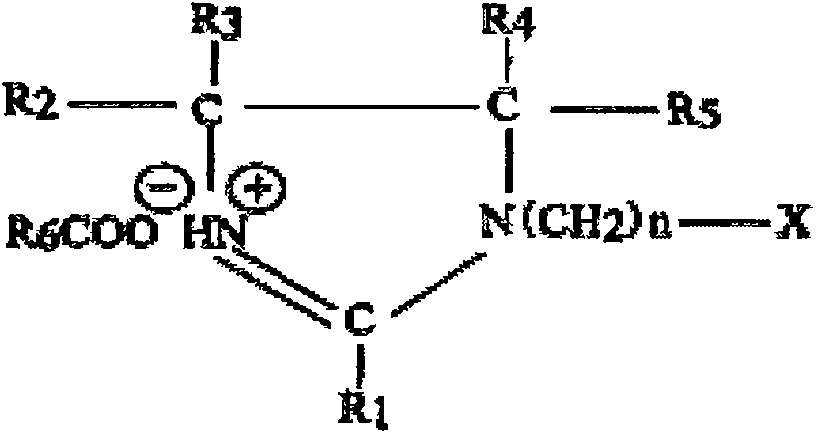

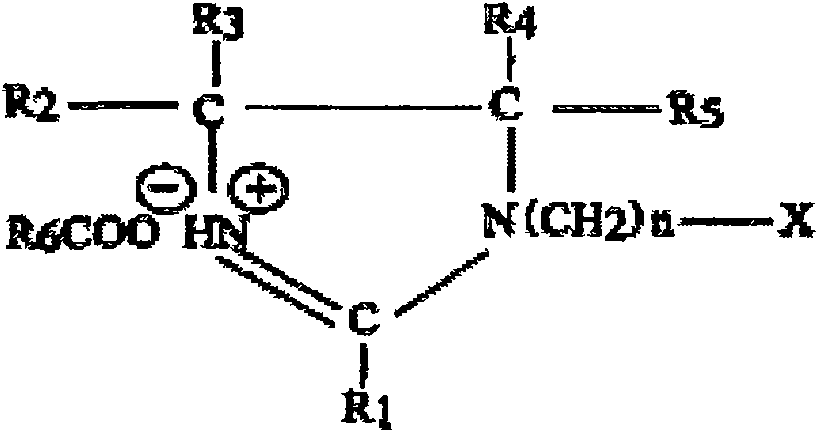

[0033] The imidazole derivative structural formula is as follows:

[0034]

[0035] where: R 2 , R 3 , R 4 and R 5 = H or alkyl; R 1 and R 6 =H alkyl or alkenyl; X = H 3 NOOCR 7 ; 7 = alk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com