Method and system for hot spark plug fouling detection

A spark plug and fouling technology, applied in ignition safety devices, spark ignition controllers, engine ignition, etc., can solve problems such as accumulation of fuel additives that cannot be easily removed, exhaust catalyst efficiency degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

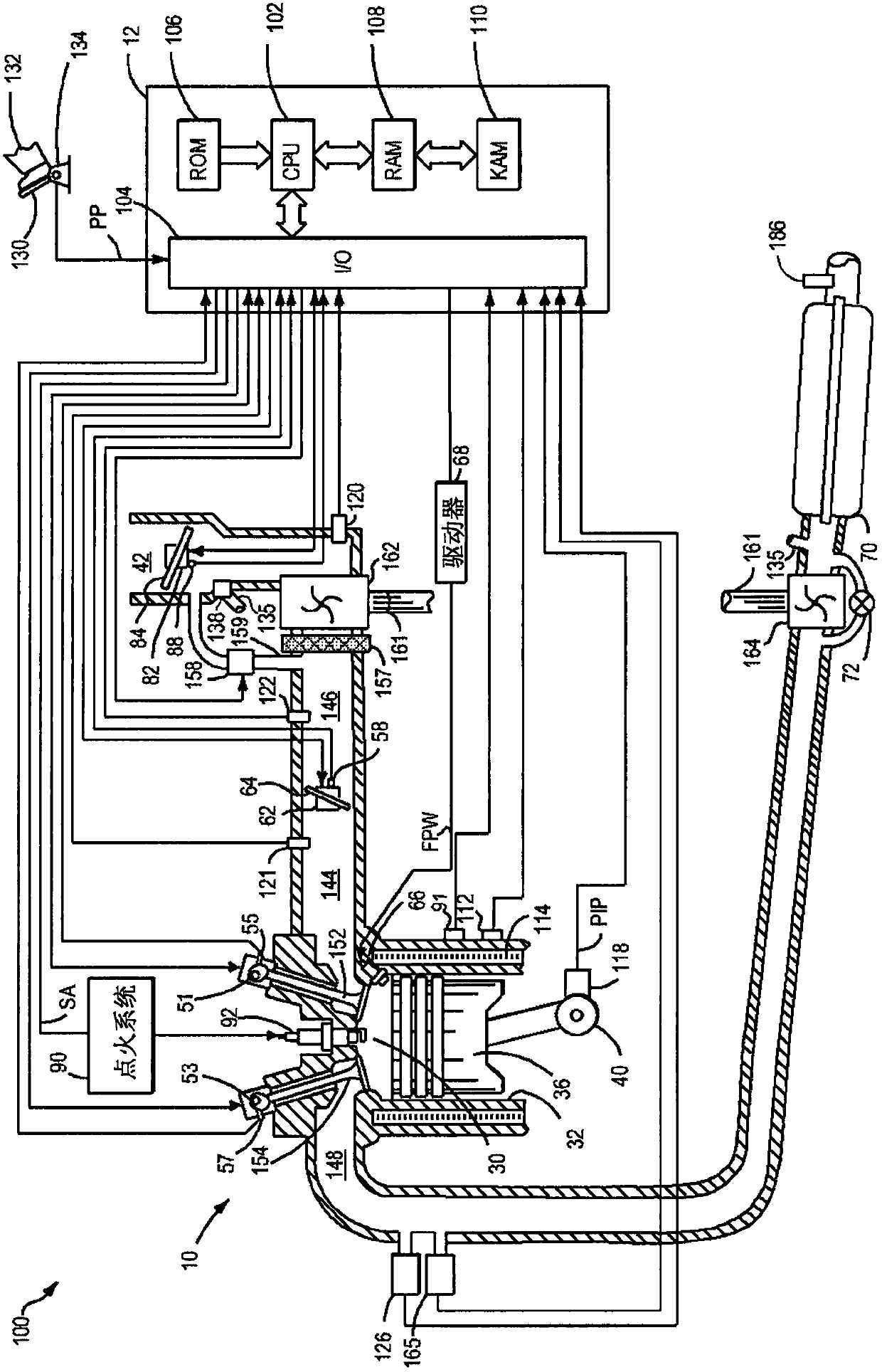

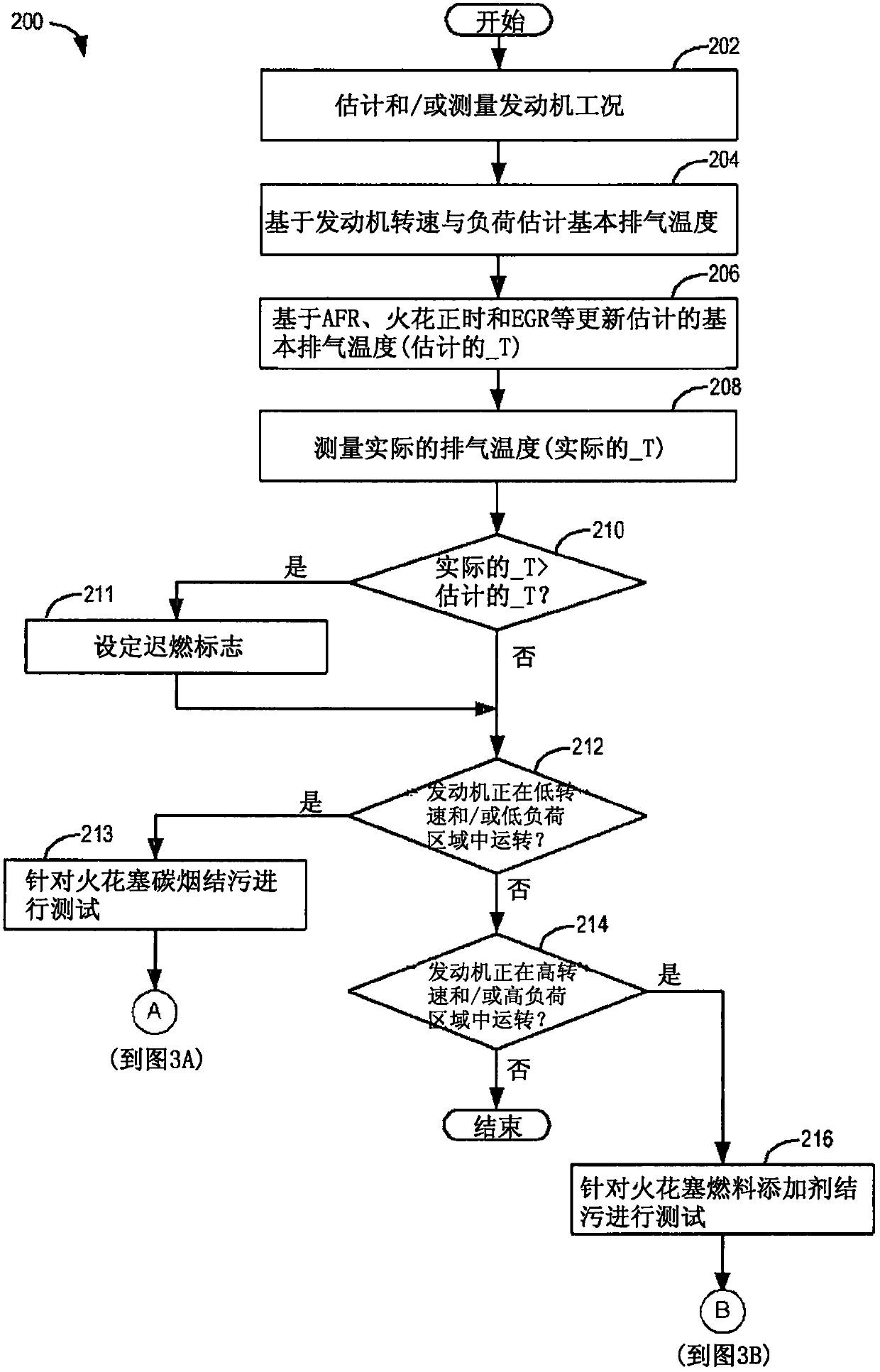

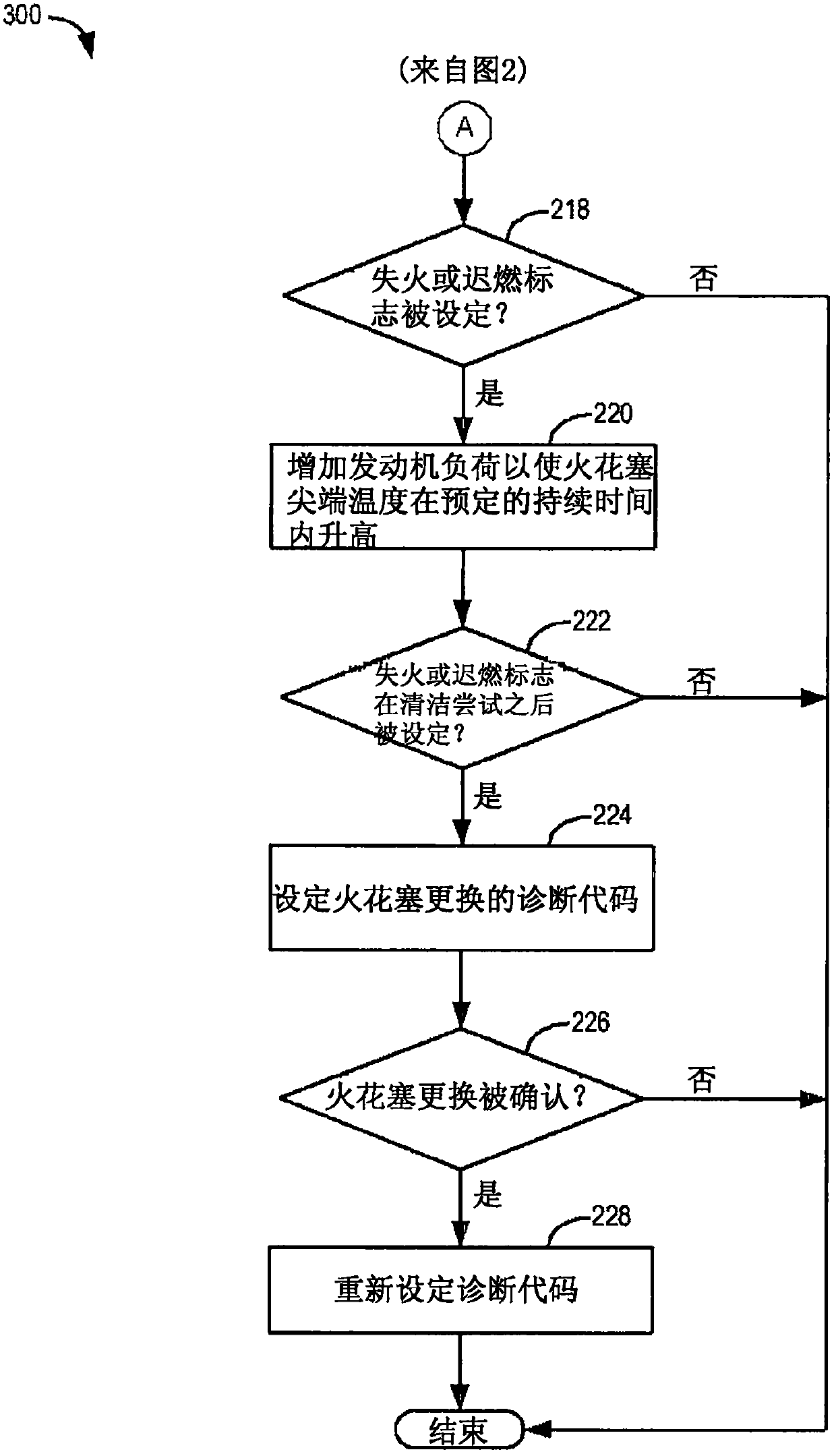

[0013] The following description relates to systems and methods for inferring fouling of spark plugs due to accumulation of fuel additives thereon. Spark plugs are included in engine systems such as figure 1 engine system). Spark plug fouling may be inferred based on a comparison between actual and estimated exhaust gas temperatures. The controller can execute control programs such as figure 2 example program) to respond to actual exhaust gas temperatures higher than those based on engine operating conditions (such as air-fuel ratio, Figure 5 ) estimated presumed spark plug thermal fouling. The controller may also monitor a number of parameters for other signals of spark plug fouling to increase confidence in spark plug fouling predictions based on exhaust gas temperature. For example, the engine controller may monitor changes in the adaptive knock term, engine pre-ignition rate, engine misfire rate, and engine exhaust oxygen sensor switching frequency (or other paramete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com