Titanium dioxide mesoporous layer of a double-size nano network and preparation method thereof

A technology of titanium dioxide and nano-network, applied in the direction of final product manufacturing, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems that are not suitable for large-scale industrial production, spin-coated films have many hole-like defects, and large-area coatings are difficult to achieve and other problems, to achieve the effect of improving photoelectric conversion efficiency, improving sunlight absorption efficiency, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the titanium dioxide mesoporous layer of the double-size nano network of the present invention, the steps are as follows:

[0025] Step 1, the TiO 2 added to ethanol for dilution, the TiO 2 The mass ratio with ethanol is 2:(5~9), the obtained TiO 2 The diluted solution was sonicated for 20-50 minutes to obtain a milky white suspension;

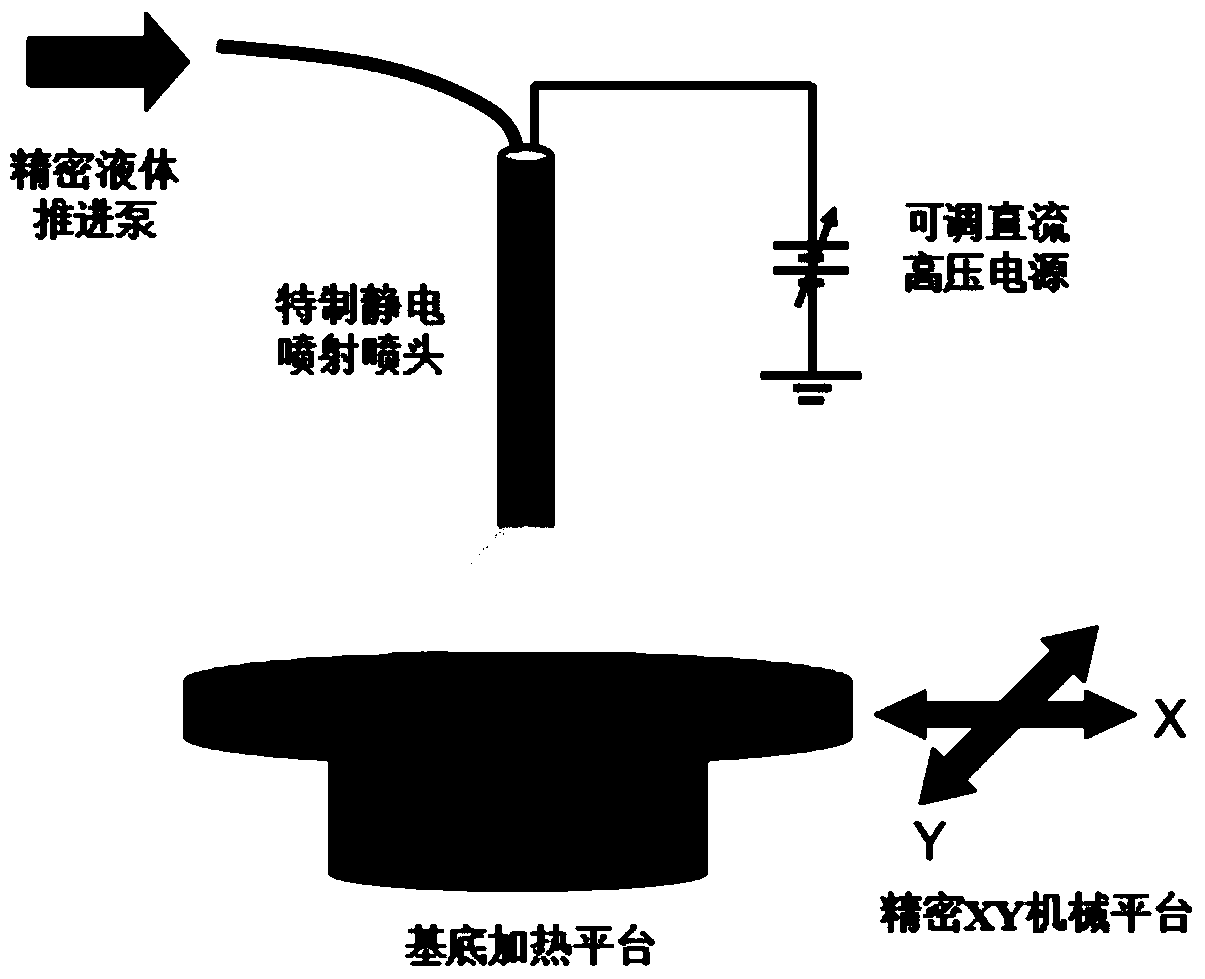

[0026] Step 2, use the electrostatic spray method to prepare the milky white suspension obtained in step 1 as TiO 2 Mesoporous layer primary film, the spraying parameters of the electrostatic spraying method are: height 10cm, flow rate 20-150μL / min, voltage 20kV, time 20-40s;

[0027] Step 3, the TiO 2 The mesoporous primary film is dried on a heating plate at 110°C to 140°C, then placed in an annealing furnace for annealing treatment, heated from room temperature to 480°C to 520°C, and then annealed at this temperature for 20 to 40 minutes to obtain TiO 2 mesoporous film.

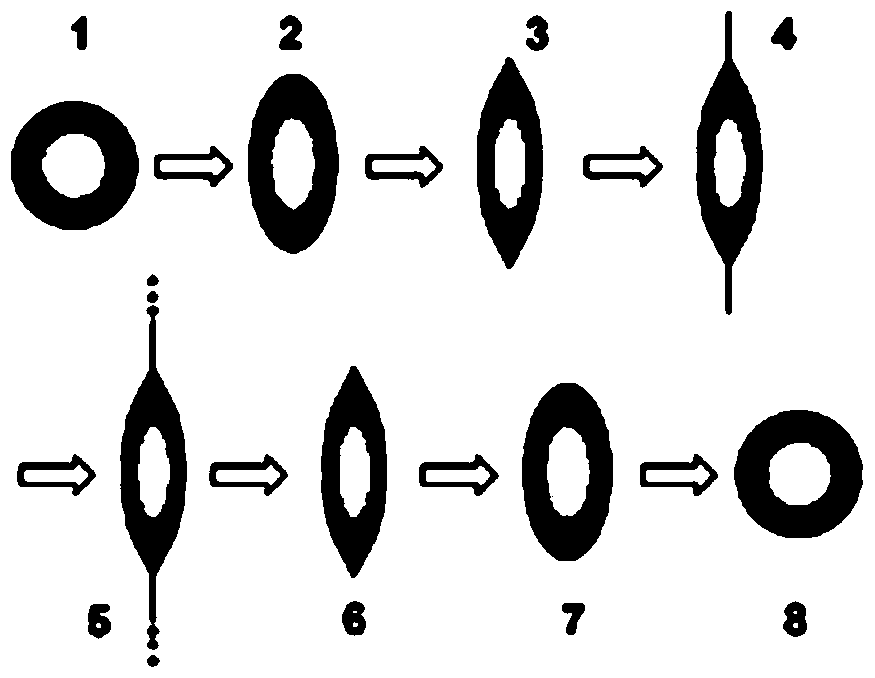

[0028] The multi-jet electrost...

Embodiment 1

[0031] The preparation method of the titanium dioxide mesoporous layer of the double-size nano network of the present invention, the steps are as follows:

[0032] Step 1, the TiO 2 added to ethanol for dilution, the TiO 2 The mass ratio with ethanol is 2:7, the obtained TiO 2 The diluted solution was sonicated for 30 minutes to obtain a milky white suspension;

[0033]Step 2, use the electrostatic spray method to prepare the milky white suspension obtained in step 1 as TiO 2 Mesoporous layer primary film, the spraying parameters of the electrostatic spraying method are: height 10cm, flow rate 60μL / min, voltage 20kV, time 30s;

[0034] Step 3, the TiO 2 The mesoporous layer primary film is dried on a heating plate at 125°C, then placed in an annealing furnace for annealing treatment, heated from room temperature to 500°C, and then annealed at this temperature for 30 minutes to obtain TiO 2 mesoporous film.

Embodiment 2

[0036] The preparation method of the titanium dioxide mesoporous layer of the double-size nano network of the present invention, the steps are as follows:

[0037] Step 1, the TiO 2 added to ethanol for dilution, the TiO 2 The mass ratio with ethanol is 2:7, the obtained TiO 2 The diluted solution was sonicated for 30 minutes to obtain a milky white suspension;

[0038] Step 2, use the electrostatic spray method to prepare the milky white suspension obtained in step 1 as TiO 2 Mesoporous layer primary film, the spraying parameters of the electrostatic spraying method are: height 10cm, flow rate 100μL / min, voltage 20kV, time 30s;

[0039] Step 3, the TiO 2 The mesoporous layer primary film is dried on a heating plate at 125°C, then placed in an annealing furnace for annealing treatment, heated from room temperature to 500°C, and then annealed at this temperature for 30 minutes to obtain TiO 2 mesoporous film.

[0040] 4) Characterization

[0041] image 3 (a) is TiO2 wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com