Modified polyolefin membrane coated with silicon dioxide layer and preparation method thereof

A polyolefin-based, silica-based technology, applied in separators/films/diaphragms/spacer elements, electrical components, non-aqueous electrolyte batteries, etc. Simple process and improved wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

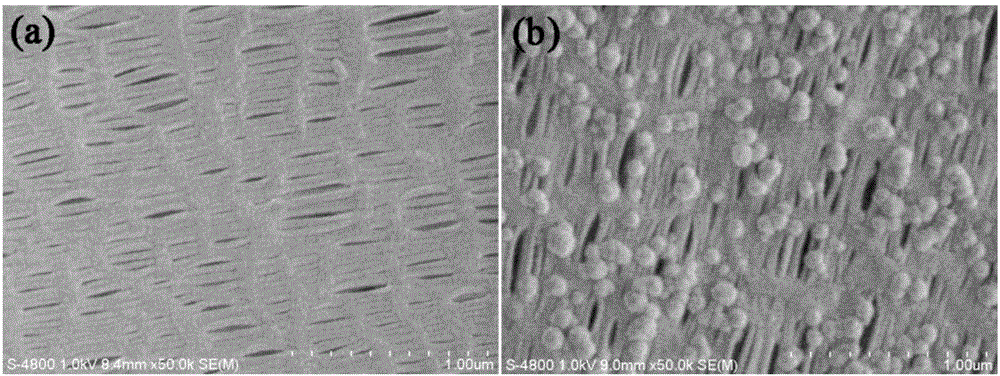

[0021] (1) Add 3 mL of water, 40 mL of ethanol, 2 mL of ammonia water, and 1 g of Tween 80 into a beaker, stir well, then add 1 mL of tetraethyl orthosilicate and stir well.

[0022] (2) Soak the PP diaphragm into the mixed solution of (1) above and soak for 2 hours.

[0023] (3) Rinse the soaked PP diaphragm several times with water and ethanol respectively.

[0024] (4) Dry the washed PP diaphragm at 60°C.

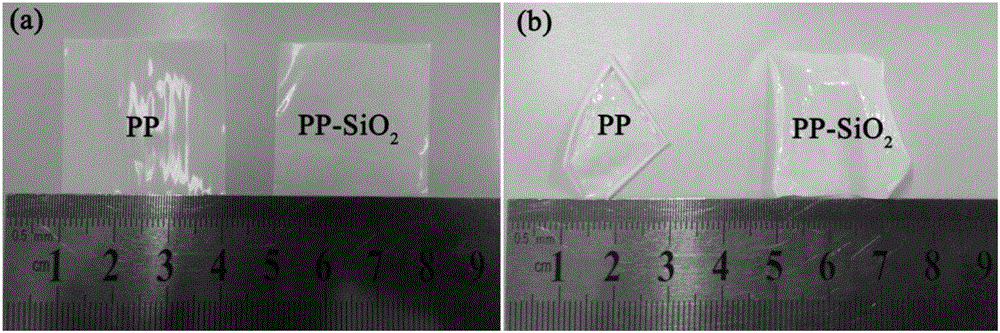

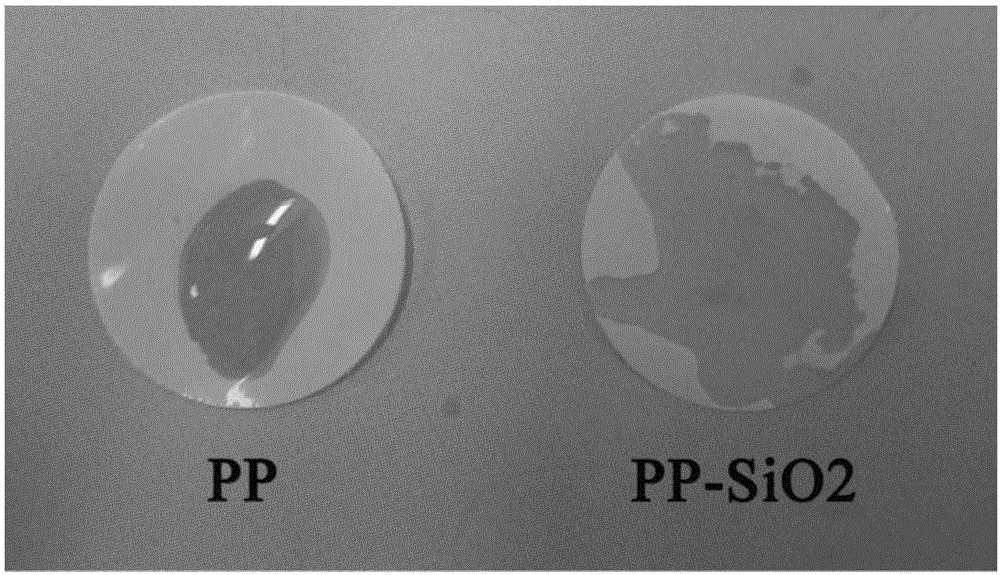

[0025] (5) The PP diaphragm coated with a silicon dioxide layer prepared under the conditions of the present invention was measured for its thermal shrinkage performance at 150° C. (see attached figure 2 ) and the wettability of the electrolyte are greatly improved (see attached image 3 ).

[0026] (6) Assembling the diaphragm into a lithium-sulfur battery, in the voltage range of 1.7-2.8V, the test shows that the material has excellent rate performance (see attached Figure 4 ). The initial discharge capacity of the separator is 937mAh g-1 at 0.2C, and the capaci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com