Full-vanadium oxidation reduction flow battery

A liquid flow battery, vanadium oxidation technology, applied in the direction of regenerative fuel cells, etc., can solve the problems affecting the electronic exchange rate of active materials, affecting the performance of the vanadium battery system, affecting the working current density and energy efficiency of the vanadium battery, so as to prolong the life, Effects of improving energy efficiency and improving electrocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

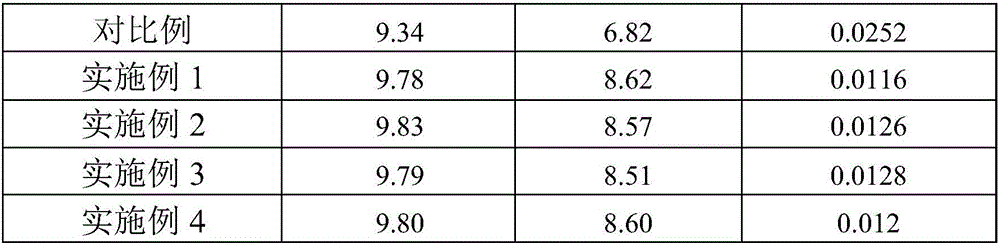

Embodiment 1

[0031] To vanadium ion concentration is 1.6mol / L, and sulfuric acid concentration is 3.0mol / L, and V(III) / V(IV) is in the 250mL vanadium electrolytic solution of 1:1, adds stannous pyrophosphate, makes Sn in the solution 2+ The concentration is 0.2mol / L, and the electrolyte solution to be tested is obtained after stirring and dissolving.

[0032] Assemble the above-mentioned electrolyte without additives, Nafion-117 diaphragm, and unmodified graphite felt electrodes into a single cell, wherein the area of the positive and negative graphite felts is 5*6cm 2 .

Embodiment 2

[0034] To the vanadium ion concentration is 1.6mol / L, sulfuric acid concentration is 3.0mol / L, V(III) / V(IV) is 1:1 in the vanadium electrolytic solution of 250mL, add tin phosphate, make Sn in the solution 4+ The concentration is 0.1mol / L, and the electrolyte solution to be tested is obtained after stirring and dissolving.

[0035] Assemble the above-mentioned electrolyte without additives, Nafion-117 diaphragm, and unmodified graphite felt electrodes into a single cell, wherein the area of the positive and negative graphite felts is 5*6cm 2 .

Embodiment 3

[0037] To the vanadium ion concentration is 1.6mol / L, sulfuric acid concentration is 3.0mol / L, V(III) / V(IV) is 1:1 in the vanadium electrolytic solution of 250mL, add stannous pyrophosphate and stannous phosphate, make solution Middle Sn 2+ The concentration is 0.1mol / L, and the electrolyte solution to be tested is obtained after stirring and dissolving.

[0038] Assemble the above-mentioned electrolyte without additives, Nafion-117 diaphragm, and unmodified graphite felt electrodes into a single cell, wherein the area of the positive and negative graphite felts is 5*6cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com