HSK ultrasonic tool handle structure with automatic tool replacement function

A tool handle structure and automatic tool change technology, applied in the accessories of tool holders, fluids using vibration, tools used in lathes, etc., can solve problems that are difficult to popularize in actual production, low ultrasonic composite processing, easy-wearing spindle speed, etc. problems, to achieve the effect of being conducive to widespread promotion and use, easy to install and implement, and improving work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

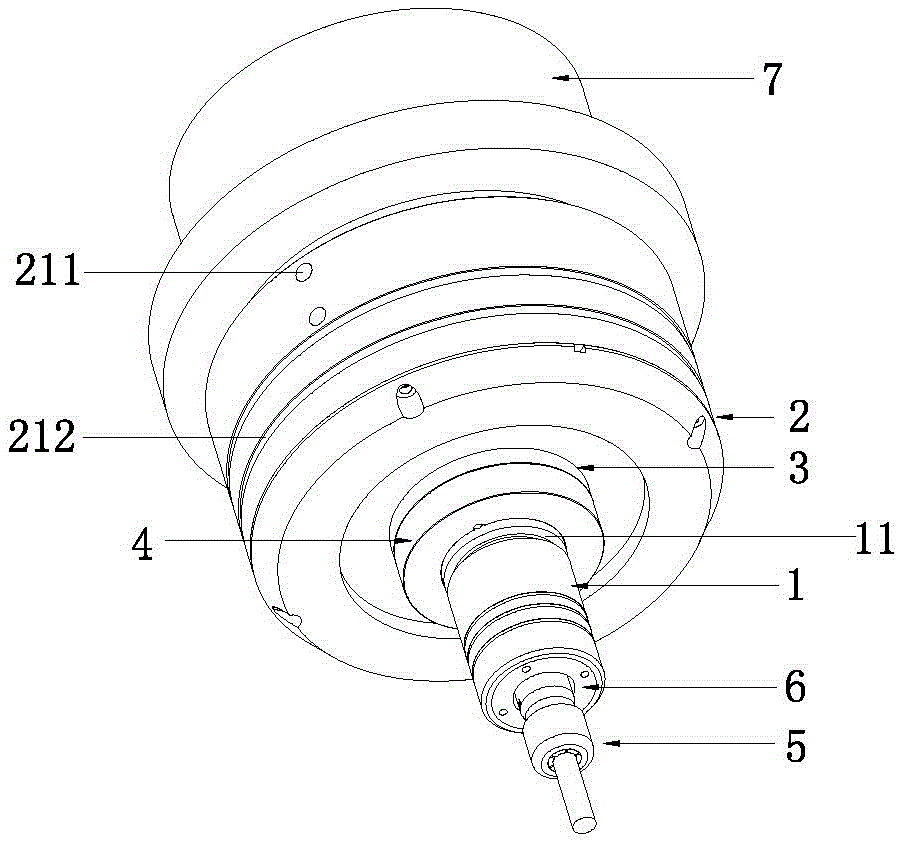

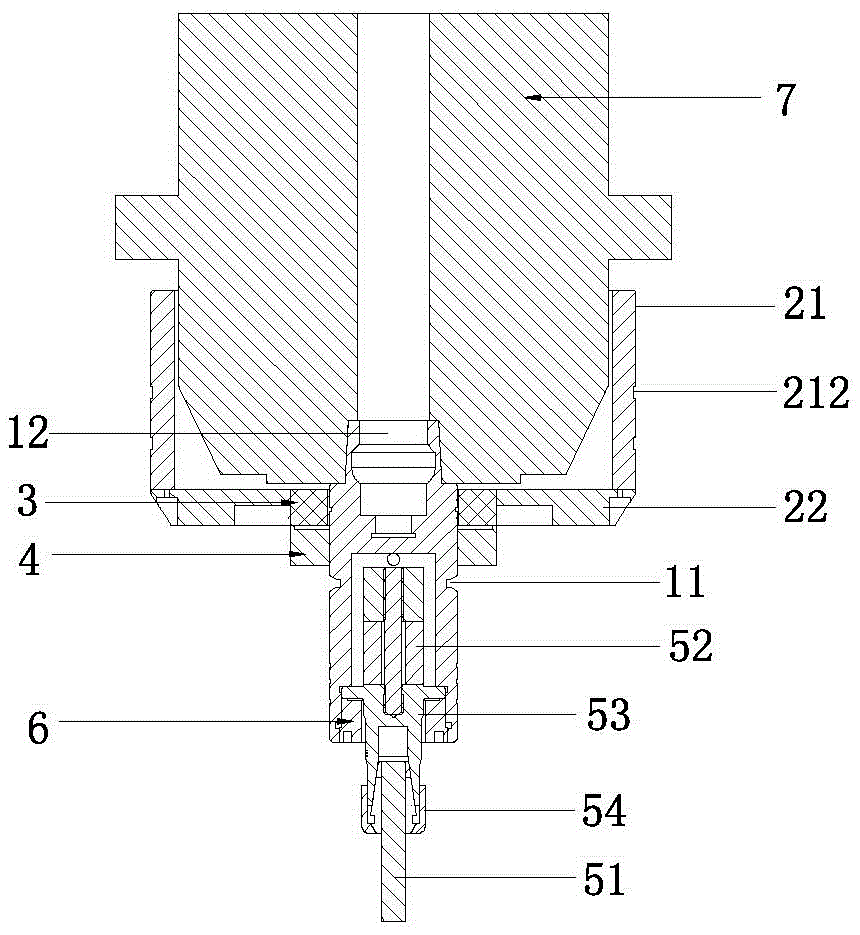

[0019] Example: see figure 1 and figure 2 , an HSK ultrasonic tool handle structure capable of automatic tool change provided by the present invention, which includes an HSK tool handle 1, a cage 2, a wireless energy transmitting end 3, a wireless energy receiving end 4, an ultrasonic transducer 5 and a pressure plate 6, The cage 2 includes a sleeve 21 and a disc 22 that closes the lower end opening of the sleeve 21. The sleeve 21 is sleeved on the electric spindle, and the center of the disc 22 is provided with a The fitting opening of the HSK tool holder 1, one end of the HSK tool holder 1 extends into the electric spindle 7 through the assembly opening, and is provided with an assembly clamp 12 for connecting with the electric spindle, and the other end There is an installation cavity for installing the ultrasonic transducer 5, the ultrasonic transducer 5 is installed on the installation cavity, and is fixed by the pressure plate 6, and the wireless power transmitting end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com