Modified chitosan and its preparation method and its application as shale inhibitor and drilling fluid and its application

A chitosan and modification technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problem of difficulty in combining inhibition effect and temperature resistance, and achieve excellent inhibition effect, inhibition of hydration and dispersion, The effect of good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

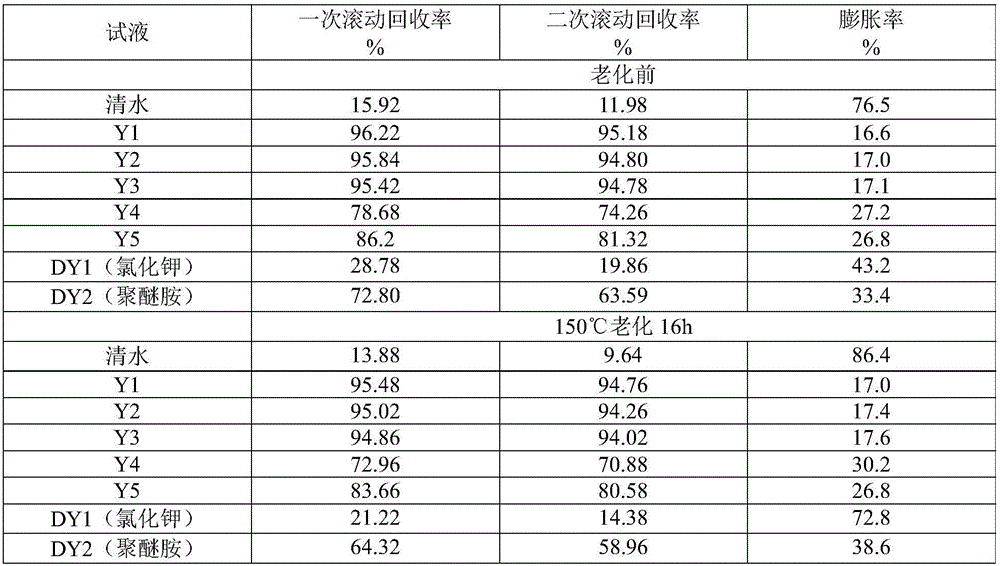

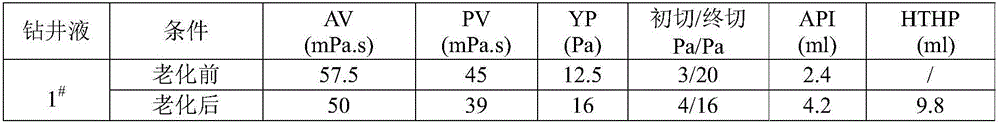

Examples

preparation example Construction

[0041] The present invention also provides a kind of preparation method of modified chitosan, the method comprises:

[0042] (1) in the presence of an alkaline compound, in a solvent, the chitosan is alkalized;

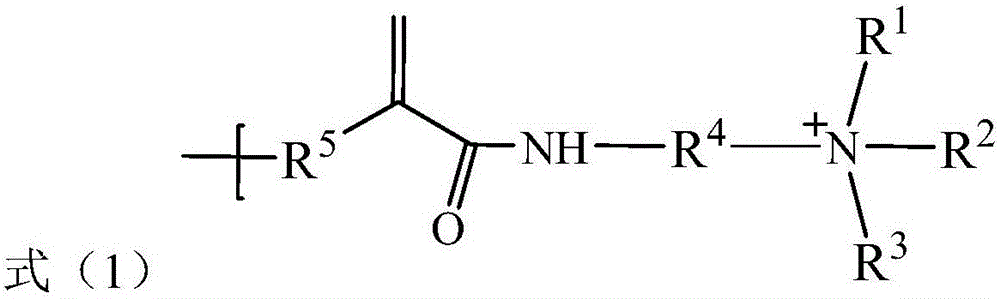

[0043] (2) carrying out quaternization reaction with the ammonium salt of the modifying group shown in the following formula (1) to the product after the alkalization treatment,

[0044] Formula 1)

[0045] Among them, R 1 -R 3 each independently selected from C1-C8 alkyl, R 4 and R 5 each independently selected from C1-C8 alkylene groups.

[0046] According to the present invention, although the product required by the present invention that can be used as a shale inhibitor can be obtained as long as it is prepared according to the preparation method of the above-mentioned modified chitosan, especially the above-mentioned method will produce the modified chitosan described above. Polycan, that is, the modified chitosan obtained by the method has a modified gr...

Embodiment 1

[0078] This embodiment is used to illustrate modified chitosan of the present invention and preparation method thereof.

[0079] (1) The chitosan of 100g (purchased from Huantai County Taili Chemical Co., Ltd., number average molecular weight is 35000, the same below) is dissolved in the isopropanol of 1300g, then adds sodium hydroxide aqueous solution (this aqueous solution concentration is 60 % by weight, in an amount such that the amount of sodium hydroxide added is 4g), and alkalized at 60°C for 4h;

[0080] (2) Continue to add (3-(2-chloromethyl)acrylamido)propyltrimethylammonium chloride (purchased from Huantai County Taili Chemical Co., Ltd. Company, hereinafter the same) aqueous solution (this aqueous solution concentration is 65% by weight, and consumption makes (3-(2-chloromethyl) acrylamido) the add-on of propyltrimethyl ammonium chloride is 100g), and stirring mix 30min; then carry out quaternization reaction at 80°C for 4h;

[0081] (3) Cool the product after th...

Embodiment 2

[0084] This embodiment is used to illustrate modified chitosan of the present invention and preparation method thereof.

[0085] (1) The chitosan of 100g is dissolved in the propanol of 1000g, then adds sodium hydroxide aqueous solution (this aqueous solution concentration is 65% by weight, consumption makes the add-on of sodium hydroxide be 4g), and at 55 DEG C chemical treatment for 3.5h;

[0086] (2) Continue to add an aqueous solution of (3-(2-chloromethyl)acrylamido)propyltrimethylammonium chloride (the concentration of the aqueous solution is 65 wt. %, the amount makes the addition of glycidyltrimethylammonium chloride 100g), and stirred and mixed for 30min; then carried out quaternization reaction at 75°C for 5h;

[0087] (3) Cool the product after the above quaternization reaction to room temperature, and adjust the pH to 7 with hydrochloric acid; then filter with suction, wash the filter cake 3 times with propanol, and dry the filter cake in a vacuum oven at 90°C Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com