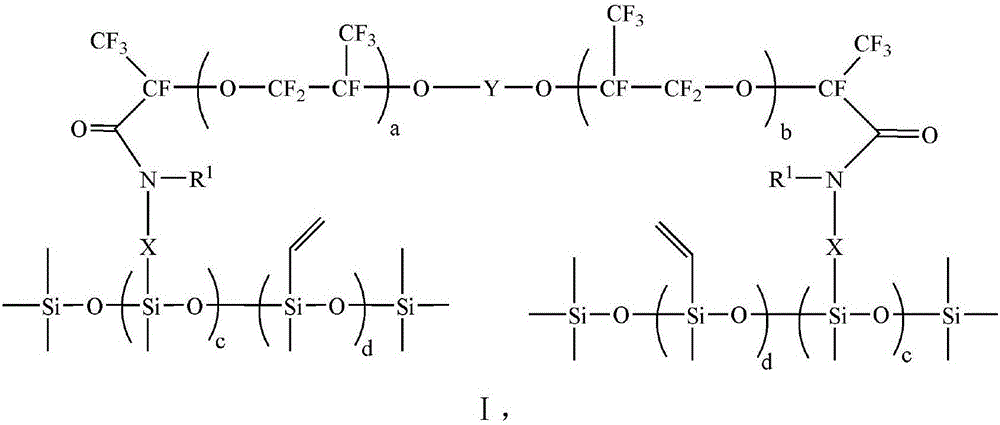

Vinyl perfluorinated polyether fluoride silicone oil and preparation method thereof

A technology of vinylamine-based silicone oil and perfluoropolyether, which is applied in the field of polyvinyl perfluoropolyether fluorosilicone oil and its preparation, and can solve the problems of low vinyl functionality, low cross-linking density, and poor mechanical properties , to achieve the effects of simple preparation method, easy operation, improved mechanical strength and acid corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

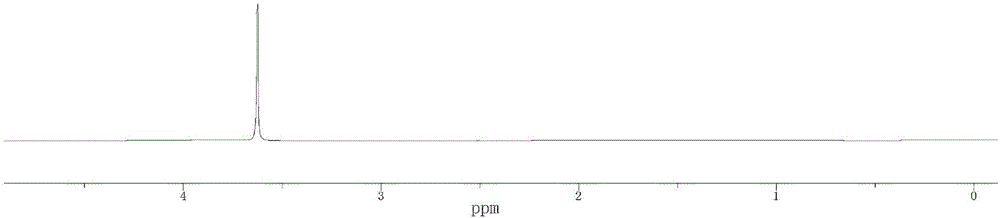

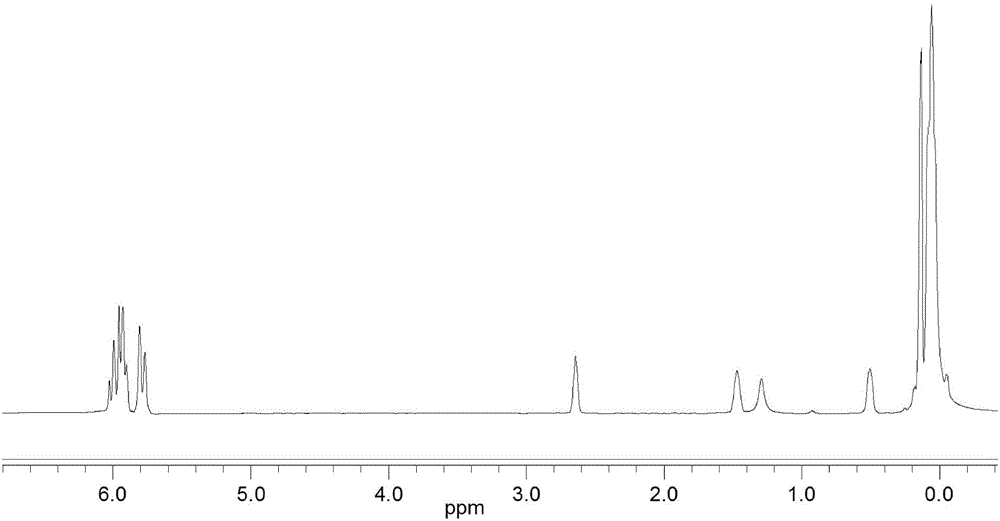

[0060] This embodiment provides a perfluoropolyether dimethyl ester, the structural formula of which satisfies the formula III, wherein, a+b=20, R 3 =CH 3 , Y=CF 2 CF 2 CF 2 .

[0061] Step 1: Add 10g of anhydrous cesium fluoride (provided by Nanjing Sitaibao Trading Co., Ltd.) and 200g of tetraethylene glycol dimethyl ether (dehydrated and distilled by metal sodium in advance) into the stainless steel reactor under the protection of high-purity nitrogen. Purification, provided by Anhui Yipu Chemical Co., Ltd.), start stirring and cool down to -5°C, add 100g perfluoromalonyl fluoride (provided by Bailingwei Technology Co., Ltd.);

[0062] Step 2: Under the condition of keeping the reaction temperature constant, stir and slowly introduce 300g of hexafluoropropylene oxide (Quzhou Jiangtian Fluorine Chemical Co., Ltd.), and keep the reaction for 12 hours;

[0063] Step 3: Cool the above reaction product to -38°C, continue to feed 2500g of hexafluoropropylene oxide, and keep ...

Embodiment 2

[0067] This embodiment provides a perfluoropolyether dimethyl ester, the structural formula of which satisfies the formula III, wherein, a+b=40, R 3 =CH 3 , Y=CF 2 CF 2 CF 2 .

[0068] In this embodiment, the mass of the added raw material hexafluoropropylene oxide was changed to 4700 g after the temperature was lowered to -38° C. in step 3, and the others were the same as in embodiment 1.

Embodiment 3

[0070] This embodiment provides a perfluoropolyether dimethyl ester, the structural formula of which satisfies the formula III, wherein, a+b=60, R 3 =CH 3 , Y=CF 2 CF 2 CF 2 .

[0071] In this embodiment, the mass of the added raw material hexafluoropropylene oxide was changed to 7000 g after the temperature was lowered to -38° C. in step 3, and the others were the same as in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com