Waterborne transparent fire-proof coating for wood materials and preparation method thereof

A technology for wood materials and fire-resistant coatings, applied in fire-resistant coatings, coatings, etc., can solve the problems of easy cracking, poor flame retardancy, and poor coating transparency, and achieve the effect of not easy cracking, good weather resistance, and transparent coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

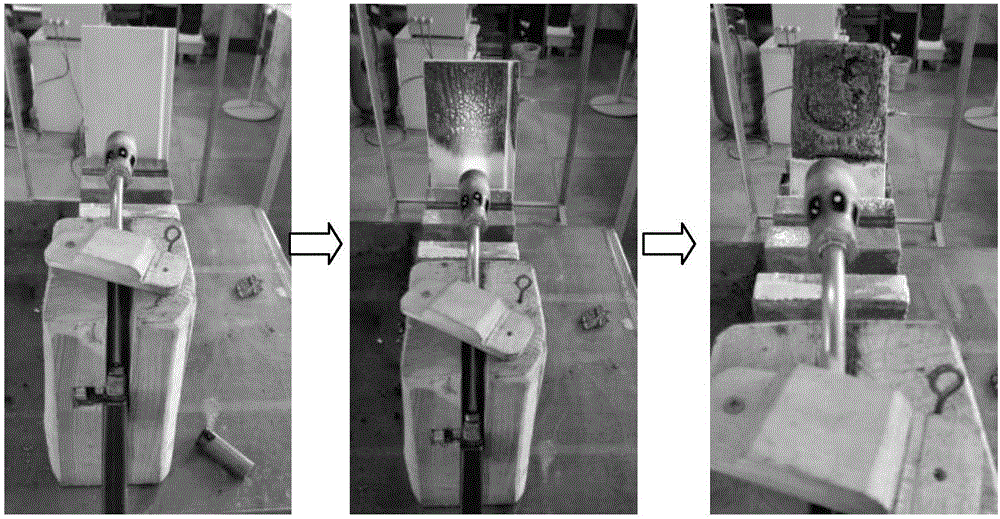

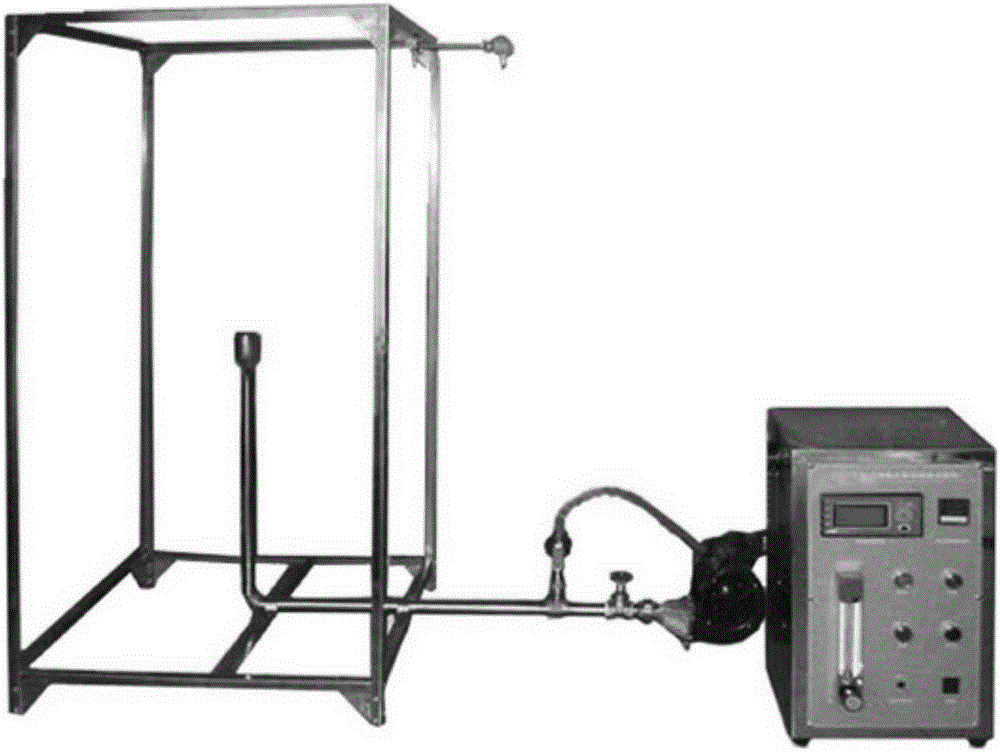

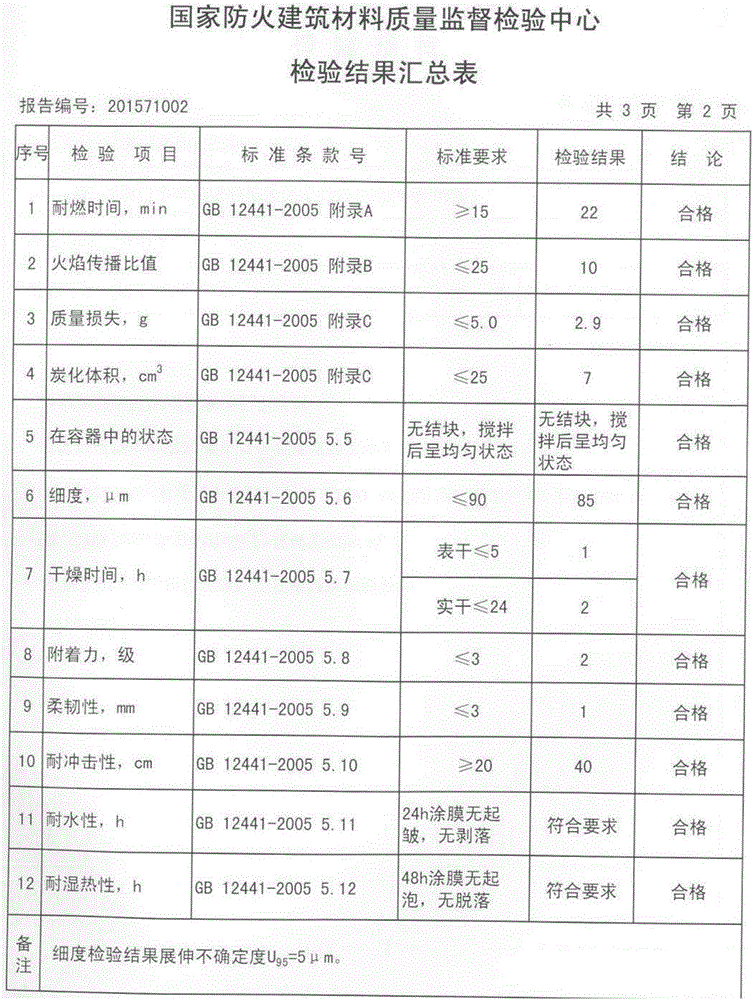

Image

Examples

Embodiment 1

[0028] (1) Weigh each raw material component according to the following weight percentages: 50% of amino resin MFR-5398-99, 7% of polysiloxane emulsion, 25% of ammonium polyphosphate, 15% of pentaerythritol, and thickener XS-167 0.3% , Light stabilizer UV1130 0.5%, UV absorber UV292 0.4%, dispersant SP-762 0.4%, film forming aid PPH 0.5%, leveling agent XS-12 0.3% and defoamer A203E 0.4%, the balance is Deionized water;

[0029] (2) Add deionized water, part of defoamer A203E, dispersant SP-762, ammonium polyphosphate and pentaerythritol into the stirring device in sequence, stir at 1500~2000r / min for 20~30min, then place it on a three-roll mill for grinding 2~3h;

[0030] (3) Put the material obtained in step (2) into a dispersing machine for dispersion at a speed of 1500-2000r / min, while adding polysiloxane emulsion to mix evenly;

[0031] (4) Reduce the speed of the disperser to 500~800r / min, continue to add the film-forming assistant PPH, amino resin, the remaining defoamer A20...

Embodiment 2

[0061] (1) Weigh each raw material component according to the following weight percentages: amino resin MFR-5398-99 45%, polysiloxane emulsion 10%, ammonium polyphosphate 25%, pentaerythritol 15%, thickener XS-167 0.5% , Light stabilizer UV1130 0.3%, ultraviolet absorber UV292 0.5%, dispersant SP-762 0.4%, film forming aid PPH 0.3%, leveling agent XS-12 0.5% and defoamer A203E 0.3%, the balance is Deionized water;

[0062] (2) Add deionized water, part of defoamer A203E, dispersant SP-762, ammonium polyphosphate and pentaerythritol into the stirring device in sequence, stir at 1500~2000r / min for 20~30min, then place it on a three-roll mill for grinding 2~3h;

[0063] (3) Put the material obtained in step (2) into a dispersing machine for dispersion at a speed of 1500-2000r / min, while adding polysiloxane emulsion to mix evenly;

[0064] (4) Reduce the speed of the disperser to 500~800r / min, continue to add the film-forming assistant PPH, amino resin, the remaining defoamer A203E, th...

Embodiment 3

[0066] (1) Weigh each raw material component according to the following weight percentages: amino resin MFR-5398-9955%, polysiloxane emulsion 5%, ammonium polyphosphate 30%, pentaerythritol 10%, thickener XS-167 0.4% , Light stabilizer UV1130 0.4%, ultraviolet absorber UV292 0.3%, dispersant SP-762 0.5%, film forming aid PPH 0.4%, leveling agent 0.4% and defoamer A203E 0.5%, the balance is deionized water ;

[0067] (2) Add deionized water, part of defoamer A203E, dispersant SP-762, ammonium polyphosphate and pentaerythritol into the stirring device in sequence, stir at 1500~2000r / min for 20~30min, then place it on a three-roll mill for grinding 2~3h;

[0068] (3) Put the material obtained in step (2) into a dispersing machine for dispersion at a speed of 1500-2000r / min, while adding polysiloxane emulsion to mix evenly;

[0069] (4) Reduce the speed of the disperser to 500~800r / min, continue to add the film-forming assistant PPH, amino resin, the remaining defoamer A203E, thickener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com