Simulation method and device for generation value of combustion characteristic of pulverized coal of power station boiler

A technology of boiler combustion and pulverized coal combustion, which is applied in the field of electric power and can solve the problems of unrealistic test benches and irregular characteristic measurements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

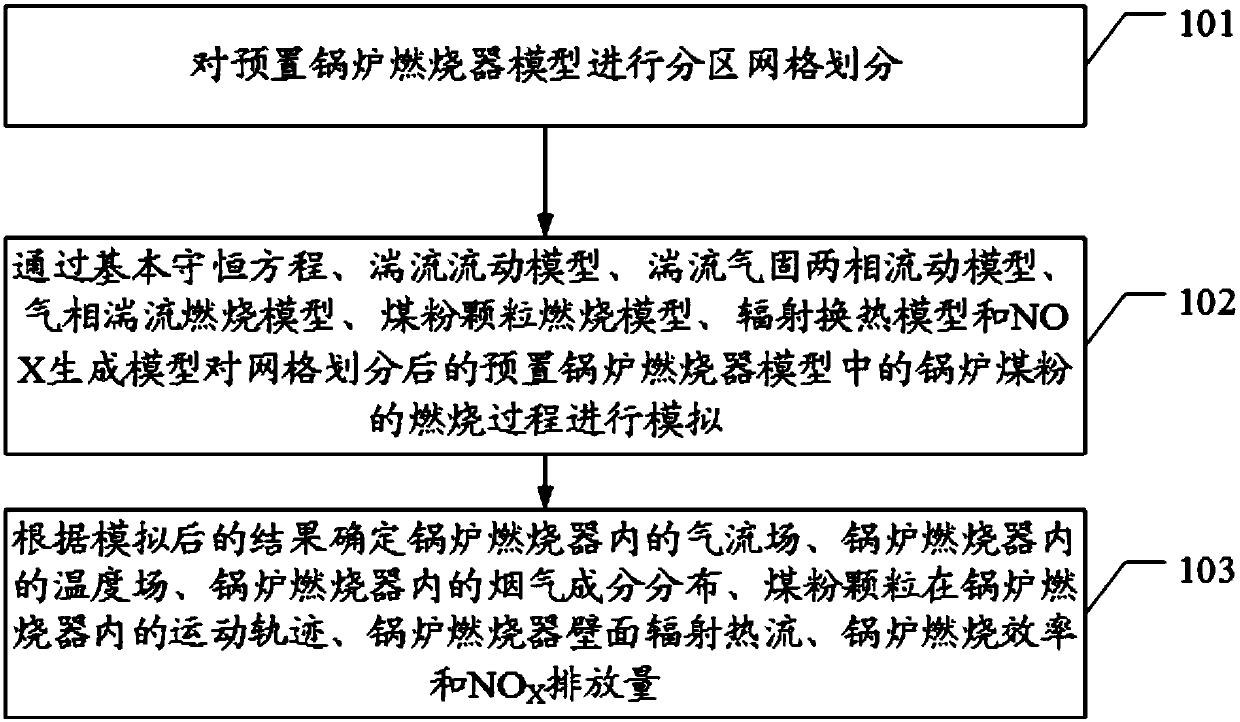

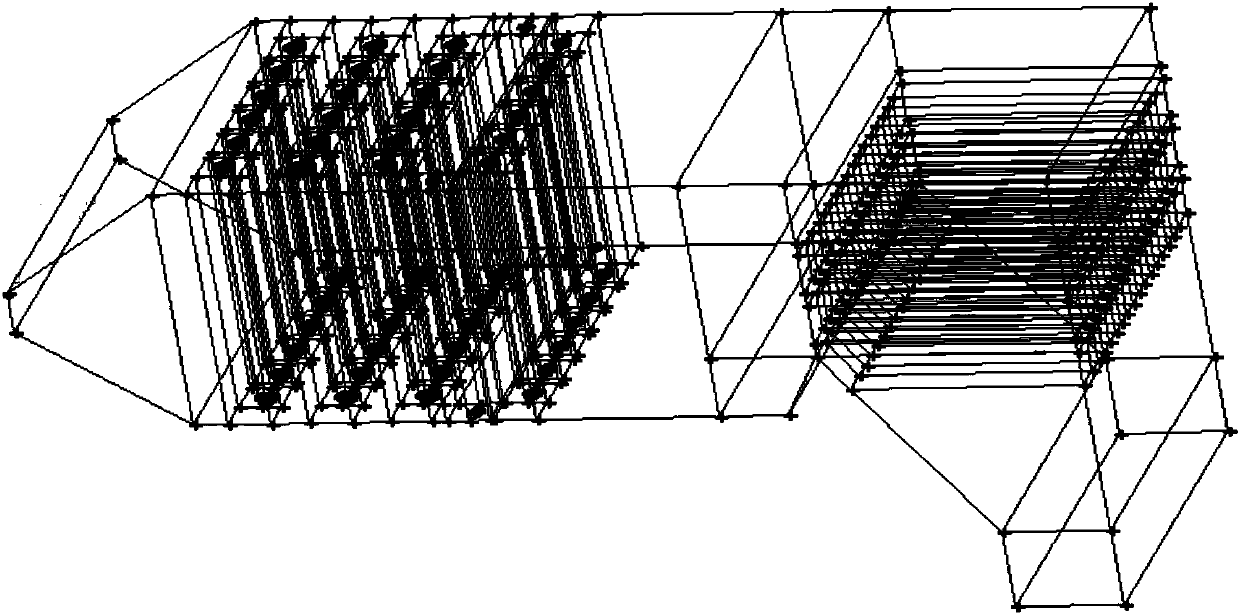

Method used

Image

Examples

Embodiment Construction

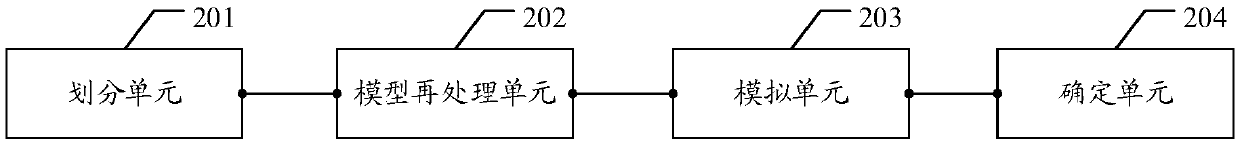

[0019] The embodiment of the present invention provides a method and device for simulating the combustion characteristics of power plant boiler pulverized coal to generate numerical values, which solves the problem that it is impractical to manufacture a full-scale model test bench due to the increasing size of the furnace. The technical problem of measuring the overall law characteristics of combustion, flow and heat transfer in the furnace.

[0020] CFD, software (Computational Fluid Dynamics), that is, computational fluid dynamics, is a branch of fluid mechanics, referred to as CFD. CFD is the product of the combination of modern fluid mechanics, numerical mathematics and computer science, and is a fringe science with strong vitality. It uses computer as a tool and applies various discrete mathematical methods to conduct numerical experiments, computer simulations and analytical research on various problems in fluid mechanics to solve various practical problems.

[0021] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com