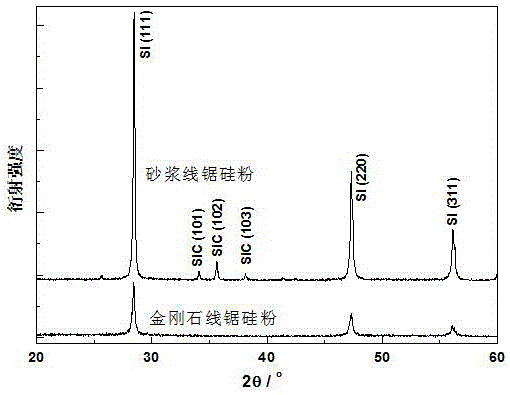

Pretreatment method of polysilicon film texturing for cutting solar cell by diamond wire saw

A technology of diamond wire saw and polysilicon wafer, which is applied in the direction of circuits, photovoltaic power generation, electrical components, etc., to achieve the effects of low cost, weak appearance, and simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

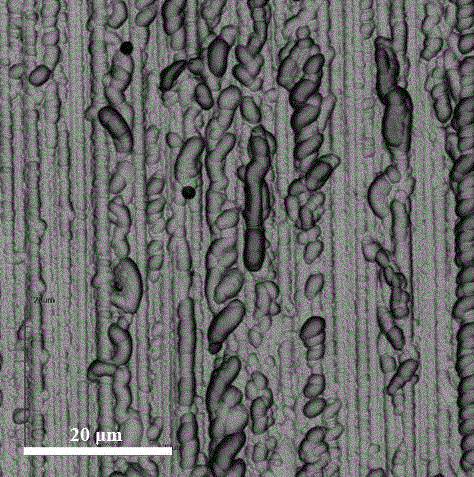

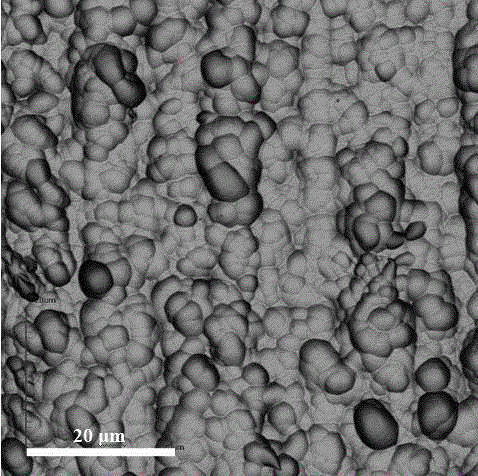

[0018] The diamond wire saw cut polysilicon wafer sample was heated to 950°C in the air in a box-type muffle furnace for 1 hour, then the power was turned off, and the temperature was lowered to below 100°C with the furnace and released from the furnace. The sample was etched for 4 minutes under conventional wet texturing conditions, rinsed with dilute alkali solution, rinsed with pure water, dried, and then measured for surface light reflectance.

Embodiment 2

[0020] The diamond wire saw cut polysilicon wafer sample was heated to 800°C in the air in a box-type muffle furnace for 1 hour, then the power was turned off, and the temperature was lowered to below 100°C with the furnace and released from the furnace. The sample was etched for 2.5 minutes under conventional wet texturing conditions, rinsed with dilute alkaline solution, rinsed with pure water, dried, and then measured for surface light reflectance.

Embodiment 3

[0022] The diamond wire saw cut polysilicon wafer sample was heated to 700°C in the air in a box-type muffle furnace for 2 hours, then the power was turned off, and the temperature was lowered to below 100°C with the furnace. The sample was etched for 1.5 minutes under conventional wet texturing conditions, rinsed with dilute alkali solution, rinsed with pure water, dried, and then measured for surface light reflectance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com