Multi-shield ammo box

A kind of ammunition box, multi-layer technology, applied in the direction of ammunition, ammunition storage, conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problem of inability to meet the technical requirements of new ammunition multi-protection packaging boxes, poor box structure sealing performance, Reduce problems such as sealing performance, achieve the effects of improving mechanical strength and thermodynamic stability, reducing product weight, and high production efficiency

Active Publication Date: 2014-11-05

秦皇岛耀华装备集团股份有限公司

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the past, aiming at the performance limitations of HIPS plastics, the method of simply increasing the thickness of the packaging box shell was often used, that is, the use of alternative methods such as increasing the mass ratio and cost of packaging materials in the packaging, reducing the sealing performance, etc. to make up for the material. Insufficient in strength and rigidity, however, this can no longer meet the technical requirements of the new ammunition multi-protection packaging box

Therefore, there is an urgent need to solve the high temperature sensitivity (hot soft and cold brittle), low elastic modulus (low rigidity of the box), high volume resistance (static insulation, electromagnetic wave transmission) and poor sealing performance of the box structure of the existing HIPS plastic materials. Key technical issues can ensure that the new plastic ammunition box not only has general technical performance but also has multiple protection functions, and can meet all the technical requirements of the new type of ammunition for the box with a high performance-price ratio

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Login to View More

Abstract

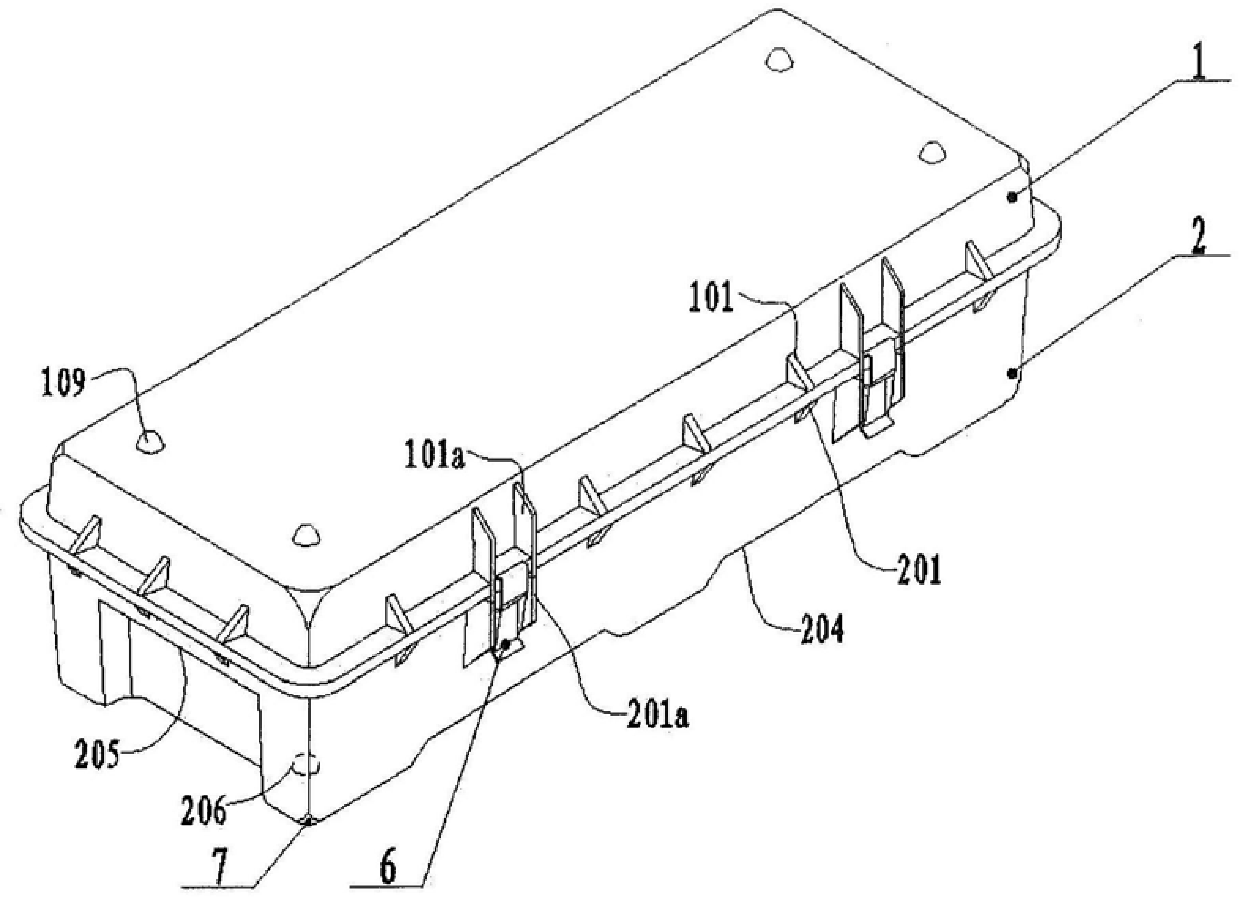

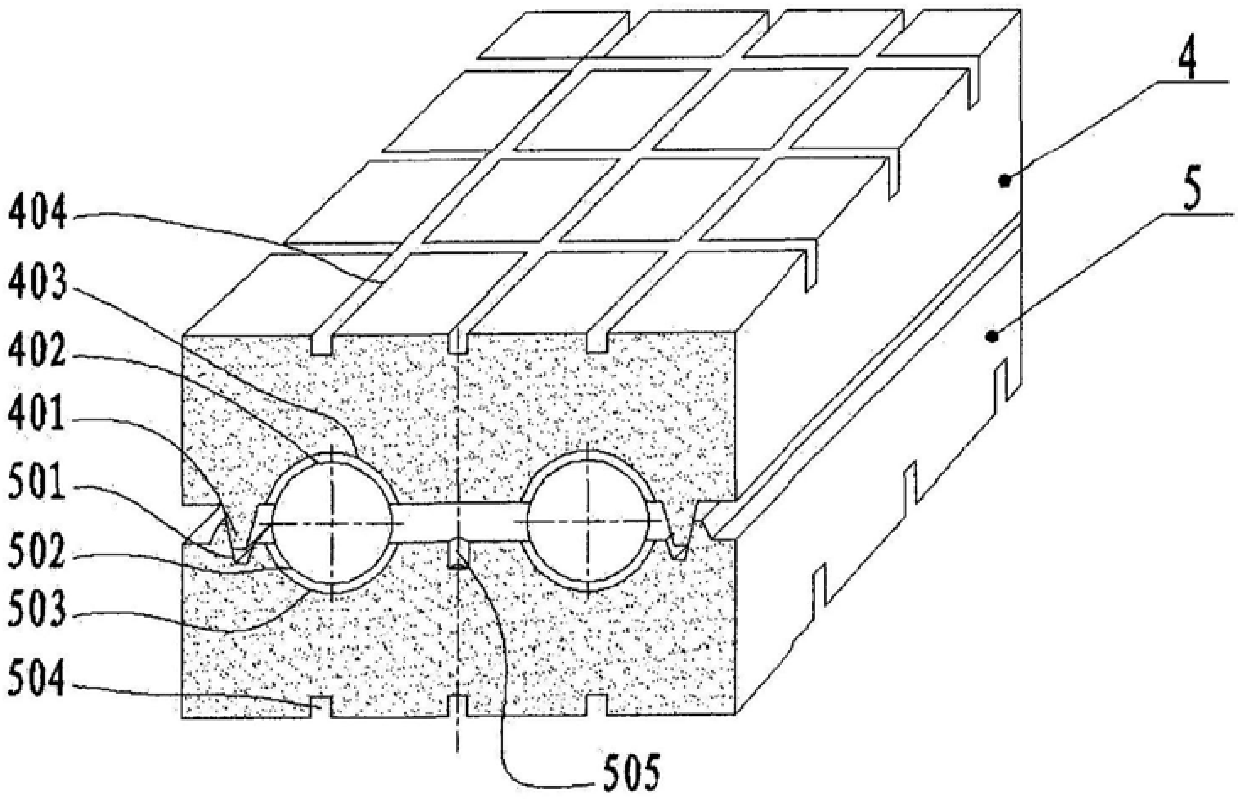

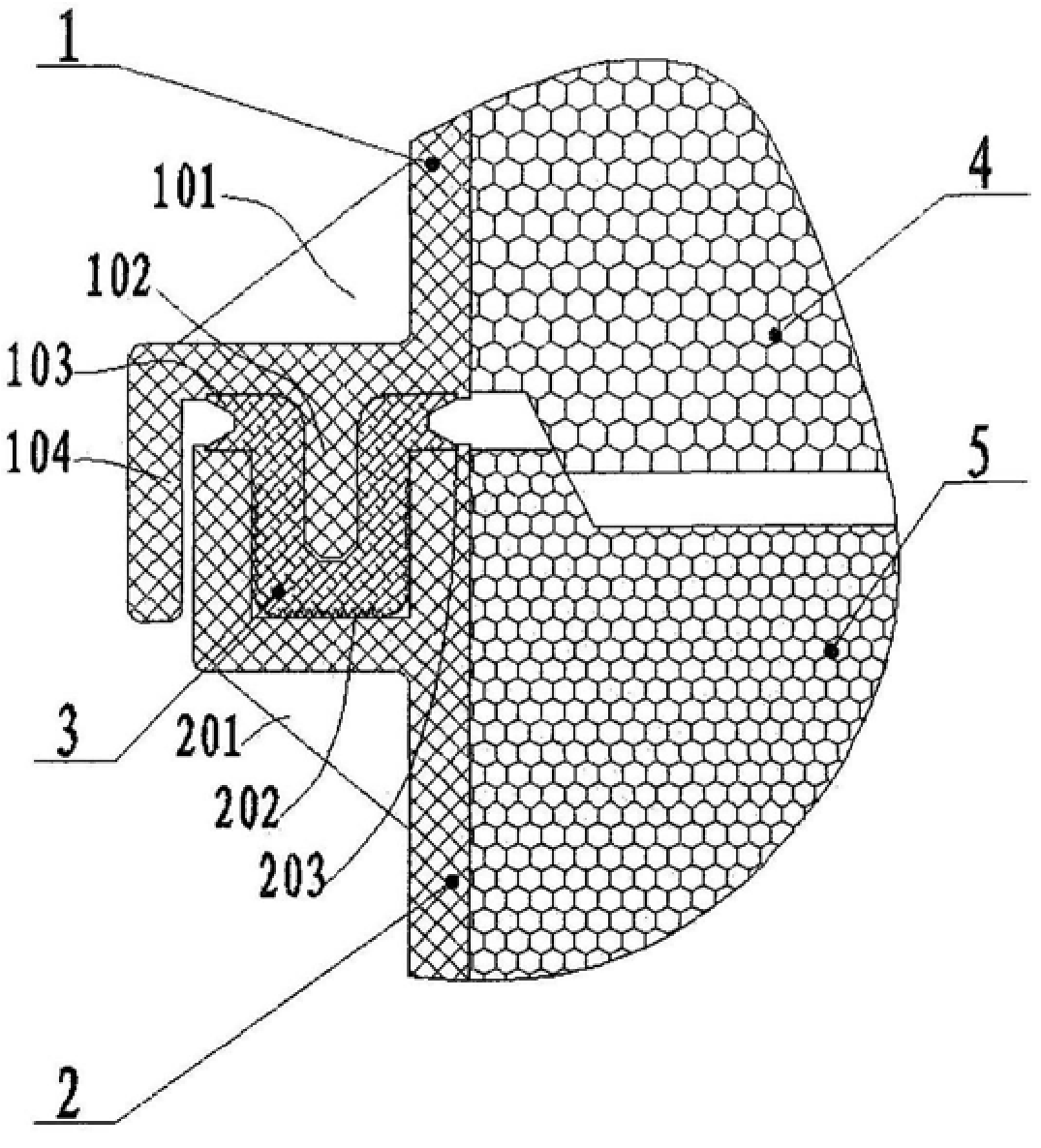

The invention belongs to the field of packaging equipment for weapons and equipment, and in particular relates to an ammunition box with multiple protective functions, including upper and lower box bodies, inner lining blocks and other components. The box body is injection-molded with high-impact polystyrene reinforced with carbon fiber short filaments; the inner liner is expanded polystyrene, and its surface is coated with an antistatic layer; at the joint of the box body, a tongue-shaped composite seal and an elastic body are installed. The airtight cavity has a double-sealed structure; a reinforced structure is added to the weak point of the drop; various types of projectile linings can be used. The present invention is an electrostatic subconductor as a whole, its strength is higher than that of high-impact polystyrene, and it has multiple protection functions such as moisture-proof, anti-collision, anti-static and anti-electromagnetic interference, and good sealing performance; the present invention adopts mature raw materials and processes for production, It has the characteristics of easy-to-obtain and recyclable materials, stable process, short production cycle, reliable function, high cost performance, suitable for packaging standardization and containerized transportation, etc., and can be used for multi-protection ammunition boxes required by new ammunition.

Description

Multi-shield ammo box technical field The invention relates to the field of packaging equipment for weapons and equipment, in particular to a multi-protection ammunition box. Background technique Ammunition is an important ordnance item that is launched to a target area with the help of a weapon (or other delivery vehicle), and damages the target through explosion or achieves other tactical tasks. Conventional ammunition generally consists of a cartridge and a warhead, which are filled with propellant powder, explosives, launch fuze and explosive fuze. Because these fillings inside the ammunition are extremely dangerous inflammable and explosive substances, if they are not handled properly during storage and transportation, such as encountering interference from external factors such as high temperature, open flames, violent vibrations, static sparks, and electromagnetic waves, it may cause Spontaneous combustion and self-explosion, resulting in major accidents. At the s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F42B39/26H01B1/24C09D175/04

Inventor 付秀君孙刚黎燕杜丽云程涛王伟章韬倪晓利

Owner 秦皇岛耀华装备集团股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com