Composite powdery sewage treatment agent for PVA-containing desizing waste water and preparation method of composite powdery sewage treatment agent

A sewage treatment agent, desizing wastewater technology, applied in water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, sterilization/microdynamic water/sewage treatment, etc., the recovery rate can only reach 60%. -70%, the removal rate can only reach 60-70%, and the requirements of environmental protection and recycling are not met, and the effects of excellent coagulation performance, high recovery rate and easy production are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

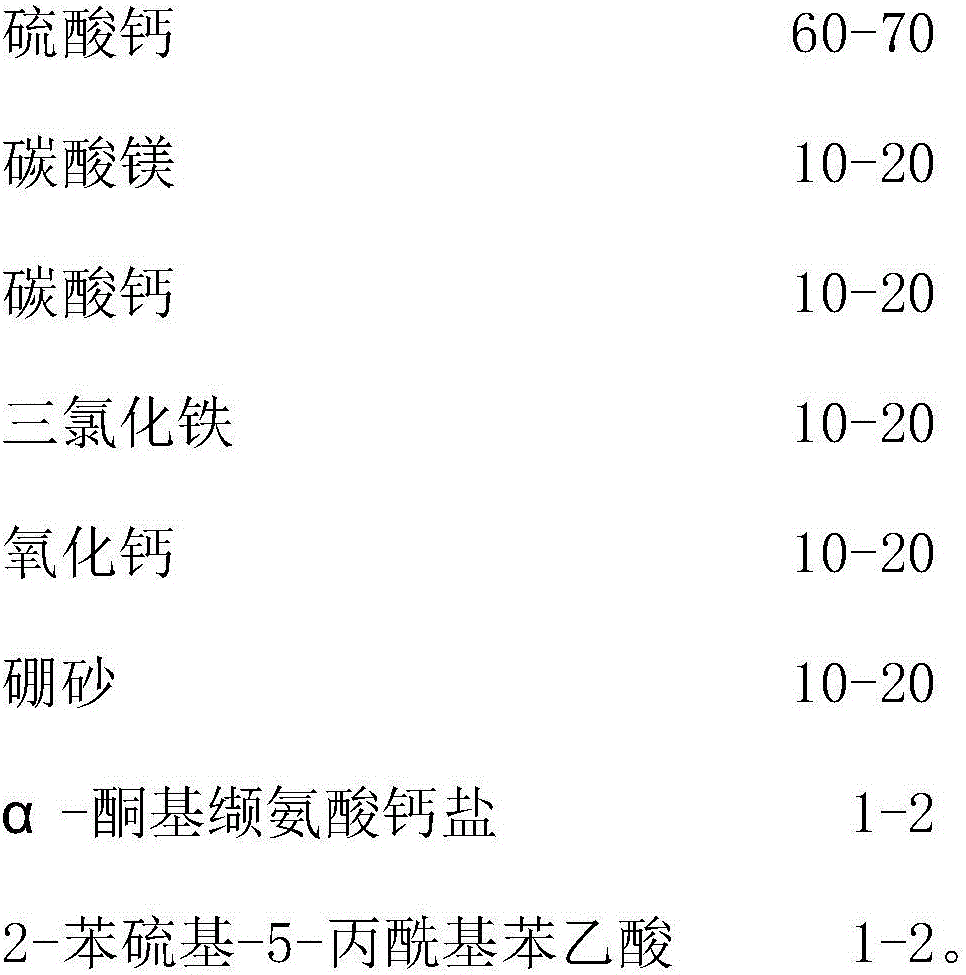

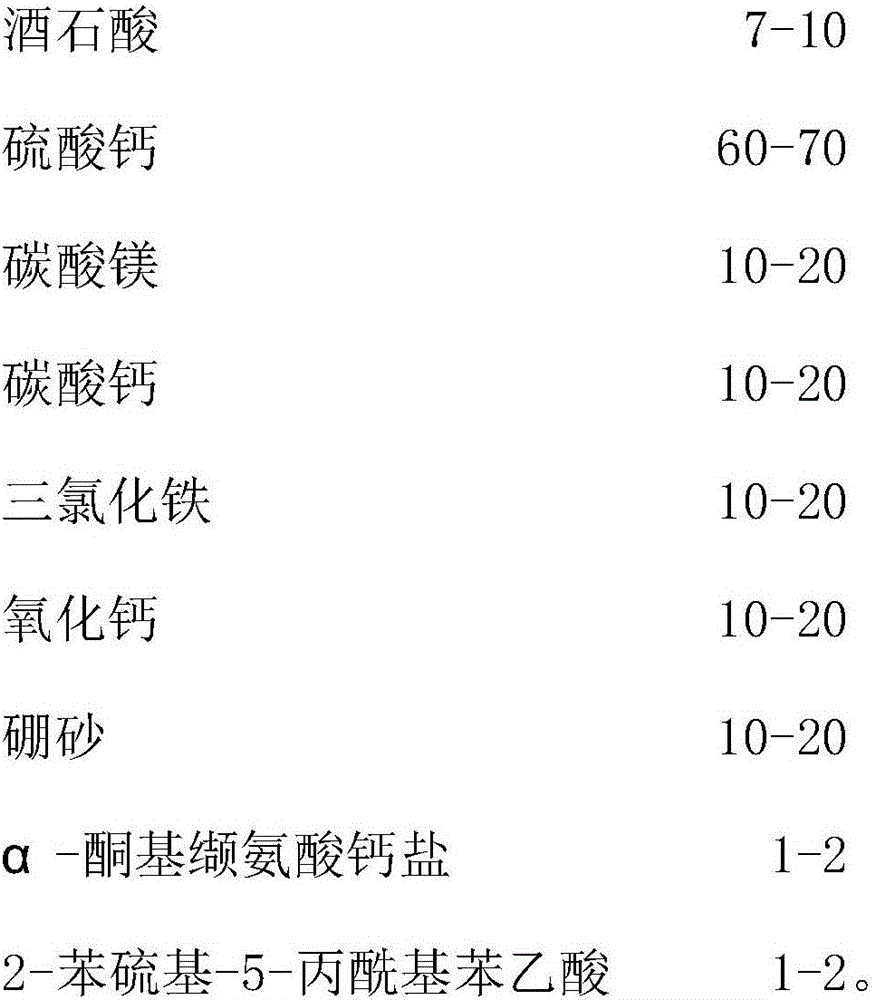

Method used

Image

Examples

Embodiment 1

[0019] Mix 7 parts by weight of 80 mesh tartaric acid with 1 weight part of 80 mesh 2-phenylthio-5-propionylphenylacetic acid for 50 minutes, then add 1 weight part of 80 mesh α-ketovaline calcium salt, and mix for 50 minutes , then add 60 parts by weight of 80 mesh calcium sulfate, mix for 50 minutes, then add 10 parts by weight of 80 mesh magnesium carbonate, mix for 40 minutes, then add 10 parts by weight of 80 mesh calcium carbonate and mix for 40 minutes, then add 10 parts by weight of 80 mesh calcium carbonate Ferric chloride, mixed for 40 minutes, then added 10 parts by weight of 80-mesh calcium oxide and mixed for 40 minutes, then added 10 parts by weight of 80-mesh borax, and mixed for 120 minutes.

Embodiment 2

[0021] Mix 7 parts by weight of 200 mesh tartaric acid with 1.6 parts by weight of 180 mesh 2-phenylthio-5-propionylphenylacetic acid for 90 minutes, then add 1.5 parts by weight of 160 mesh α-ketovaline calcium salt, and mix for 90 minutes , then add 70 parts by weight of 200 mesh calcium sulfate, mix for 90 minutes, then add 20 parts by weight of 200 mesh magnesium carbonate, mix for 50 minutes, then add 20 parts by weight of 200 mesh calcium carbonate and mix for 50 minutes, then add 20 parts by weight of 200 mesh calcium carbonate Ferric chloride, mixed for 50 minutes, then added 20 parts by weight of 200-mesh calcium oxide and mixed for 50 minutes, then added 20 parts by weight of 200-mesh borax, and mixed for 130 minutes.

Embodiment 3

[0023] Mix 8 parts by weight of 400 mesh tartaric acid and 2 parts by weight of 400 mesh 2-phenylthio-5-propionylphenylacetic acid for 120 minutes, then add 2 parts by weight of 400 mesh α-ketovaline calcium salt, and mix for 120 minutes , then add 70 parts by weight of 400 mesh calcium sulfate, mix for 120 minutes, then add 15 parts by weight of 400 mesh magnesium carbonate, mix for 60 minutes, then add 20 parts by weight of 400 mesh calcium carbonate and mix for 60 minutes, then add 20 parts by weight of 400 mesh three Ferric chloride, mixed for 60 minutes, then added 20 parts by weight of 400 mesh calcium oxide and mixed for 60 minutes, then added 16 parts by weight of borax of 400 mesh, and mixed for 150 minutes.

[0024] The technical index of embodiment 1-3 is as shown in table 1:

[0025] Table 1:

[0026] Example 1 Example 2 Example 3 Density g / ㎝ 3 (20°C)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com