A kind of preparation method of sio2/tio2 anti-reflection film

An anti-reflection film and substrate technology, applied in the direction of instruments, coatings, optics, etc., can solve the problems of cumbersome implementation, changes in the microstructure of the film, difficult adjustment of the refractive index, etc., and achieve strong operability and continuously adjustable refractive index , fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

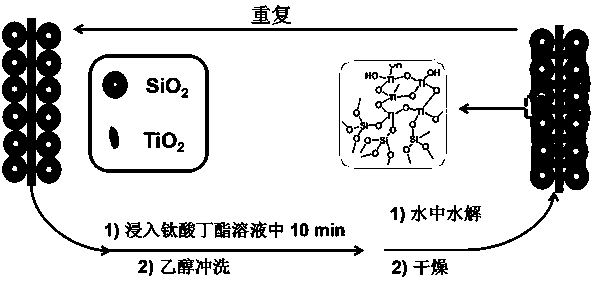

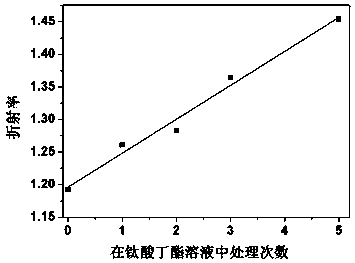

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0025] SiO of the present invention 2 / TiO 2 The preparation method of the anti-reflection film, the specific operation steps are as follows:

[0026] Step 1, mix anhydrous ethanol, ammonia water, deionized water and ethyl orthosilicate with a molar ratio of 37.6:0.17:3.25:1, stir evenly and let stand in a stable environment for about 7 days to obtain alkali-catalyzed SiO 2 Sol; SiO 2 The mass percent concentration of sol is 3%, SiO 2 The effect of sol concentration on the obtained SiO 2 Thin films (about 100nm in thickness) will have an impact; in the above reaction system, ammonia water is the catalyst, tetraethyl orthosilicate is the silicon source, and absolute ethanol is the solvent;

[0027] Step 2, add a certain amount of butyl titanate into the mixture of absolute ethanol and toluene (the volume ratio of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com